Melamine polymer type intumescent flame retardant and preparation method and application thereof

An intumescent flame retardant, melamine technology, applied in the field of melamine polymer intumescent flame retardant and its preparation, can solve the problems of low flame retardant element content, low flame retardant efficiency, narrow application range, etc., and achieve compatibility Good, little influence on processability, strong water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

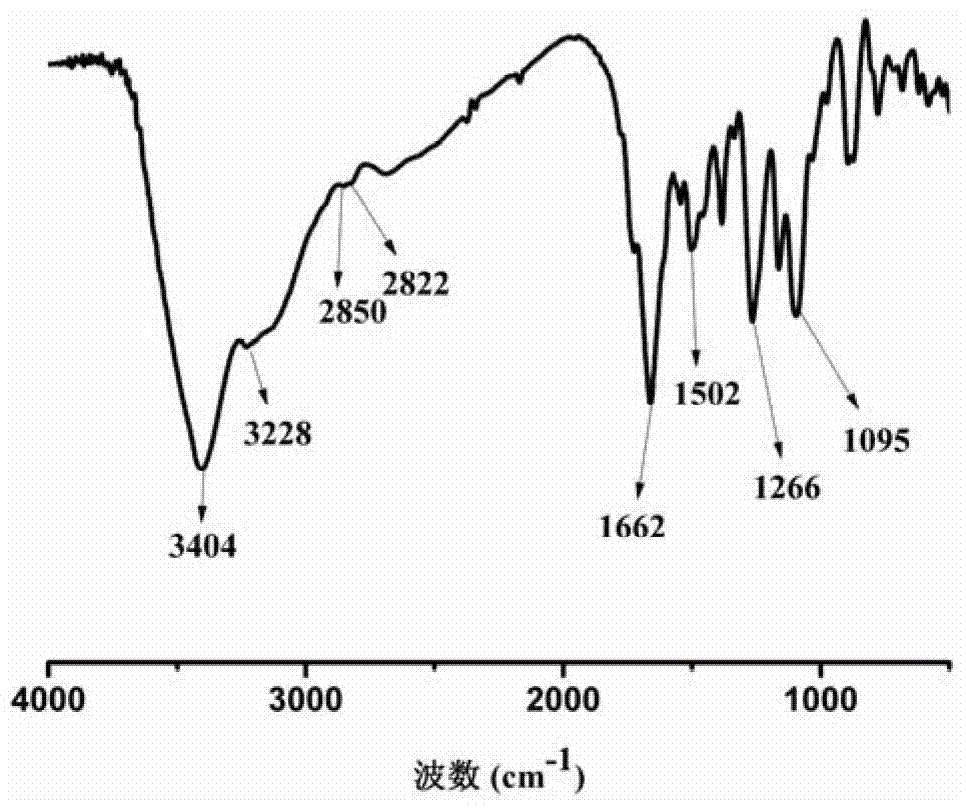

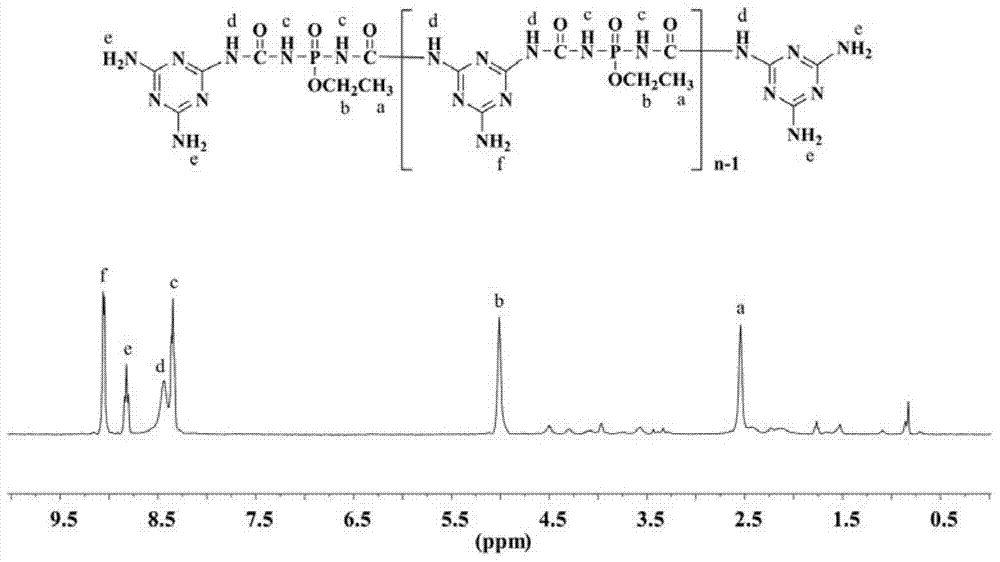

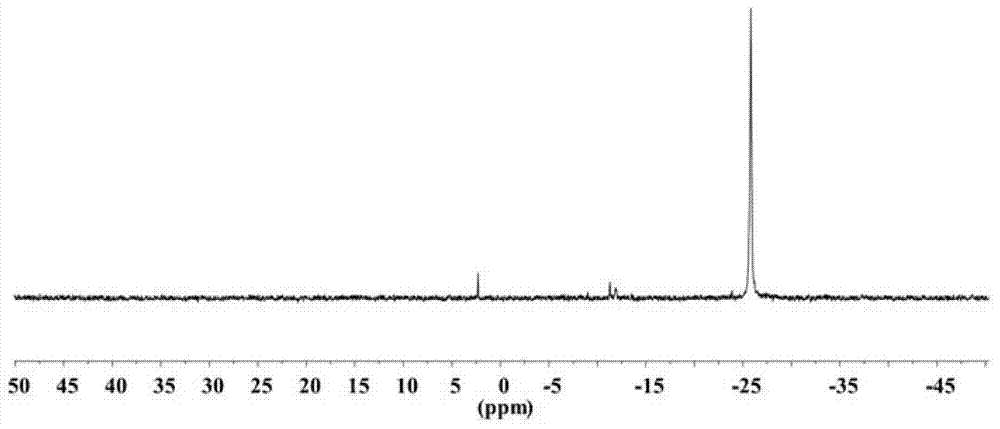

Method used

Image

Examples

Embodiment 1

[0041] Add 0.4 mol of phosphorus oxychloride and 111 ml of triethylamine into 200 ml of benzene and stir evenly, then slowly add 0.8 mol of ethyl carbamate dissolved in 200 ml of benzene into it dropwise while stirring, when the solution of ethyl carbamate After more than half of the dropwise addition, raise the temperature to 70°C, and react for 8 hours after the dropwise addition is complete; lower the temperature to 40°C, add 0.4 mol ethanol and 55 ml triethylamine to the system, stir and react for 0.5 hour, and then distill off the solvent; Disperse 0.4 mol of melamine in 400 ml of m-cresol, then add it to the reaction system, raise the temperature and stir to 190°C for 8 hours, and after the reaction, filter the reaction product, wash it, and dry it in a vacuum oven at 80°C. Obtain yellow powder melamine polymer type intumescent flame retardant PMPC1.

Embodiment 2

[0043] Add 0.4 mol of phosphorus oxychloride and 70 ml of pyridine into 200 ml of benzene and stir evenly, then slowly add 0.88 mol of methyl carbamate dissolved in 200 ml of benzene into it dropwise while stirring, when the methyl carbamate solution is added dropwise After more than half, raise the temperature to 60°C, and react for 9 hours after the dropwise addition is complete; lower the temperature to 30°C, add 0.36mol methanol and 29ml pyridine to the system, stir and react for 0.5 hours, and then distill off the solvent; disperse 0.44mol melamine In 400 ml of dimethyl sulfoxide, then added to the reaction system, heated and stirred to 180 ° C for 7 hours, after the reaction, the reaction product was filtered, washed, and dried in a vacuum oven at 80 ° C to obtain a yellow powder Melamine polymer type intumescent flame retardant PMPC2.

Embodiment 3

[0045] Add 0.4 mol of phosphorus oxychloride and 100 ml of triethylamine into 200 ml of xylene and stir evenly, then slowly add 0.72 mol of ethyl carbamate dissolved in 200 ml of xylene dropwise while stirring, when the ethyl carbamate After more than half of the ester solution has been added dropwise, raise the temperature to 80°C, and react for 8 hours after the dropwise addition is complete; lower the temperature to 40°C, add 0.44mol n-propanol and 60ml triethylamine to the system, stir and react for 1 hour, and then distill Remove the solvent; disperse 0.36mol melamine in 400 ml of nitrogen-methylpyrrolidone, then add it to the reaction system, raise the temperature and stir to 190°C for 9 hours, after the reaction, filter the reaction product, wash it, and place it in a vacuum at 80°C Dry in an oven to obtain yellow powder melamine polymer type intumescent flame retardant PMPC3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com