Preparation method and application of inorganic hybrid smoke-suppression flame retardant

A flame retardant and hybridization technology, which is applied in the preparation and application of inorganic hybrid smoke suppressing flame retardants, can solve the problems of large amount of inorganic flame retardants, poor comprehensive flame retardant effect, and difficult dispersion, and achieve the goal of retardant The effects of improved combustion efficiency, uniform dispersion, and excellent comprehensive flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

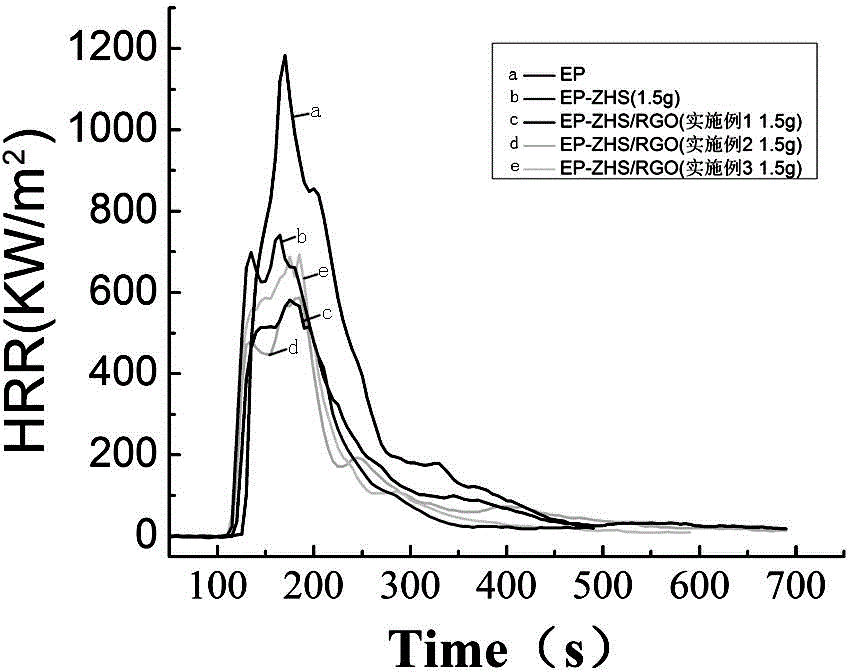

Embodiment 1

[0038] Add distilled water to graphite oxide, ultrasonically disperse evenly, and obtain a graphene oxide suspension with a concentration of 0.5 mg / mL; measure 400 mL of graphene oxide suspension into an 800 mL beaker, add 0.3201 g of Na 2 SnO 3 ·3H 2 O, making Na in the solution 2 SnO 3 The concentration of ZnSO is 3 mmol / L, and stirred at room temperature for 20 minutes to form a uniform solution; then weigh 0.3451g of ZnSO 4 ·7H 2 O was added to the above solution, stirred at room temperature for 30 minutes, and the solution was placed in a 500mL polytetrafluoroethylene hydrothermal reaction kettle, reacted at 160°C for 8 hours, filtered under reduced pressure, washed twice with deionized water, and the precipitate was freeze-dried for 12 Hours, grind black powder inorganic hybrid smoke suppression flame retardant.

Embodiment 2

[0040] Add distilled water to graphite oxide, ultrasonically disperse evenly, and obtain a graphene oxide suspension with a concentration of 0.5 mg / mL; measure 400 mL of graphene oxide suspension into an 800 mL beaker, add 0.6402 g of Na 2 SnO 3 ·3H 2 O, making Na in the solution 2 SnO 3 The concentration is 6 mmol / L, stir at room temperature for 15 minutes to form a uniform solution; then weigh 0.6902g of ZnSO 4 ·7H 2 O was added to the above solution, stirred at room temperature for 30 minutes, and the solution was placed in a 500mL polytetrafluoroethylene hydrothermal reaction kettle, reacted at 160°C for 8 hours, filtered under reduced pressure, washed twice with deionized water, and the precipitate was freeze-dried for 12 Hours, grind black powder inorganic hybrid smoke suppression flame retardant.

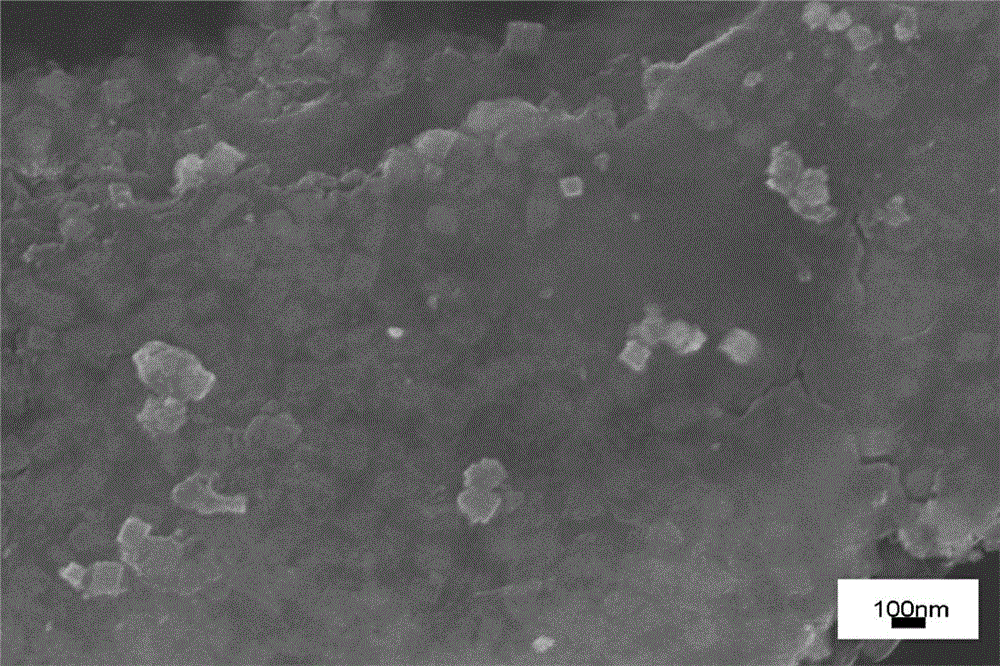

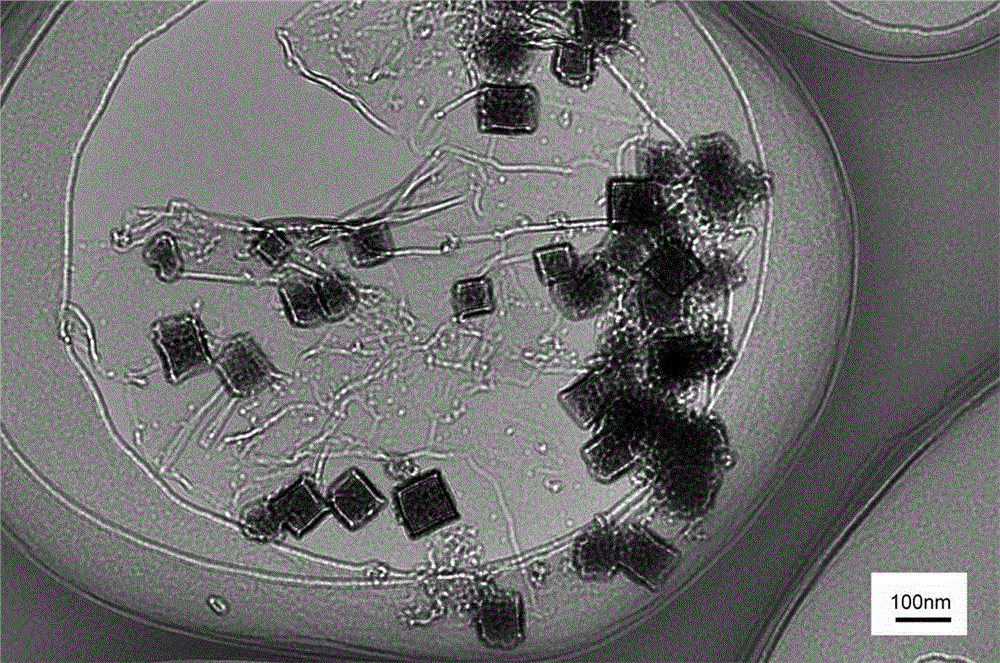

[0041] Taking Example 2 as an example, the prepared powdery inorganic hybrid smoke-suppressing flame retardant is scanned and transmitted with an electron microscope, an...

Embodiment 3

[0043] Add distilled water to graphite oxide, ultrasonically disperse evenly, and obtain a graphene oxide suspension with a concentration of 0.5mg / mL; measure 400mL of graphene oxide suspension into an 800mL beaker, add 0.9603g of Na 2 SnO 3 ·3H 2 O, making Na in the solution 2 SnO3 The concentration of ZnSO is 9 mmol / L, and stirred at room temperature for 20 minutes to form a uniform solution; then weigh 1.0353g of ZnSO 4 Add 7H2O to the above solution, stir at room temperature for 30 minutes, put the solution in a 500mL polytetrafluoroethylene hydrothermal reaction kettle, react at 160°C for 8 hours, filter under reduced pressure, wash twice with deionized water, and freeze-dry the precipitate After 12 hours, grind to obtain a black powdery inorganic hybrid smoke suppressing and flame retardant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com