Polyamide-based intumescent flame retardant carbon-forming agent containing piperazine structure in main chain and preparation method and application thereof

A technology of intumescent flame retardant and polyamide, applied in the field of polyamide intumescent flame retardant charcoal agent and its preparation, which can solve the difficulty of deteriorating the mechanical properties, dielectric properties and processing properties of materials, and increasing the balance of various performance indicators , unsatisfactory charring effect, etc., to achieve the effect of simple and easy preparation process, improved vertical combustion level, and large molecules

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

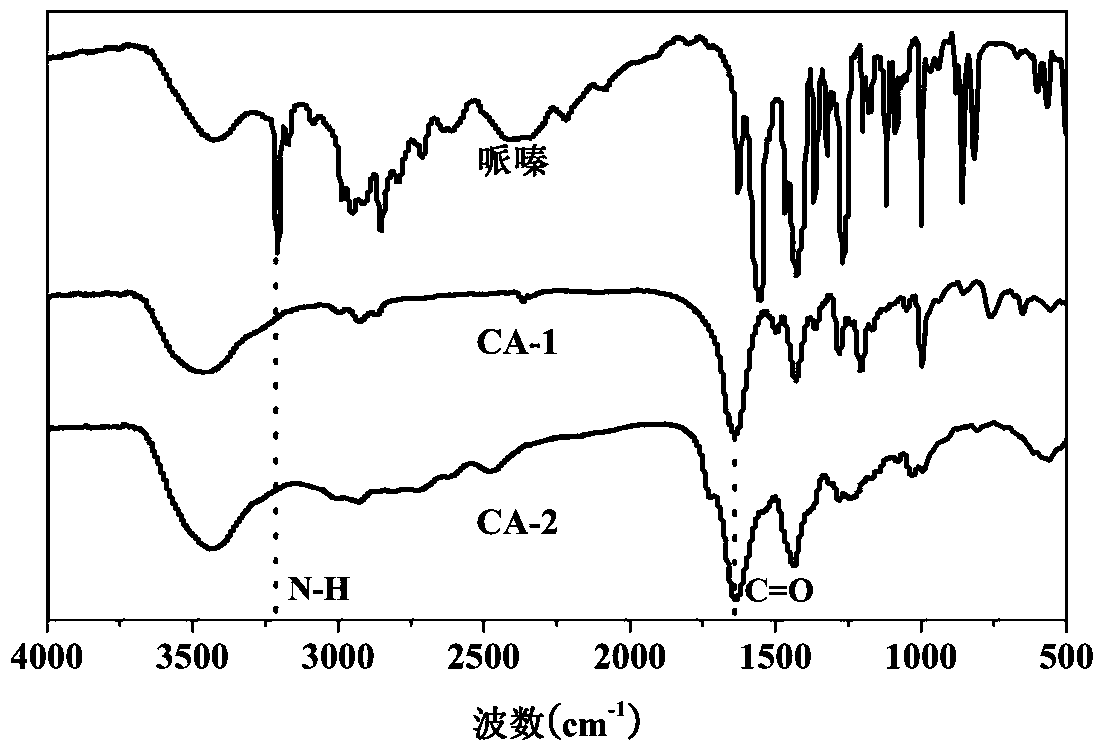

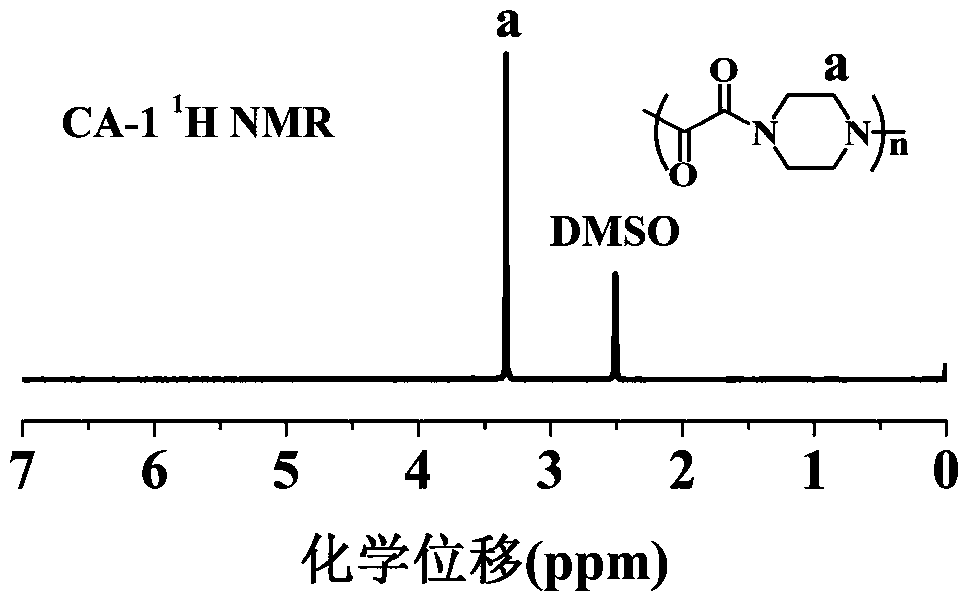

[0036] Add 1 mol of oxalyl chloride into 1L of chloroform to make it evenly dispersed, and record it as liquid A; then add 1 mol of anhydrous piperazine and 2.0 mol of triethylamine acid-binding agent to 500 mL of chloroform to make it Disperse evenly, record it as liquid B, then add liquid B dropwise into liquid A while stirring at 0°C, raise the temperature to 60°C after the dropwise addition, and react for 12 hours. After the reaction is completed, remove the chloroform, add water to the remaining solid, stir and make a slurry, then suction filter, repeat this process at least 3 times, collect the solid, and dry it to obtain the charcoal agent CA-1.

Embodiment 2

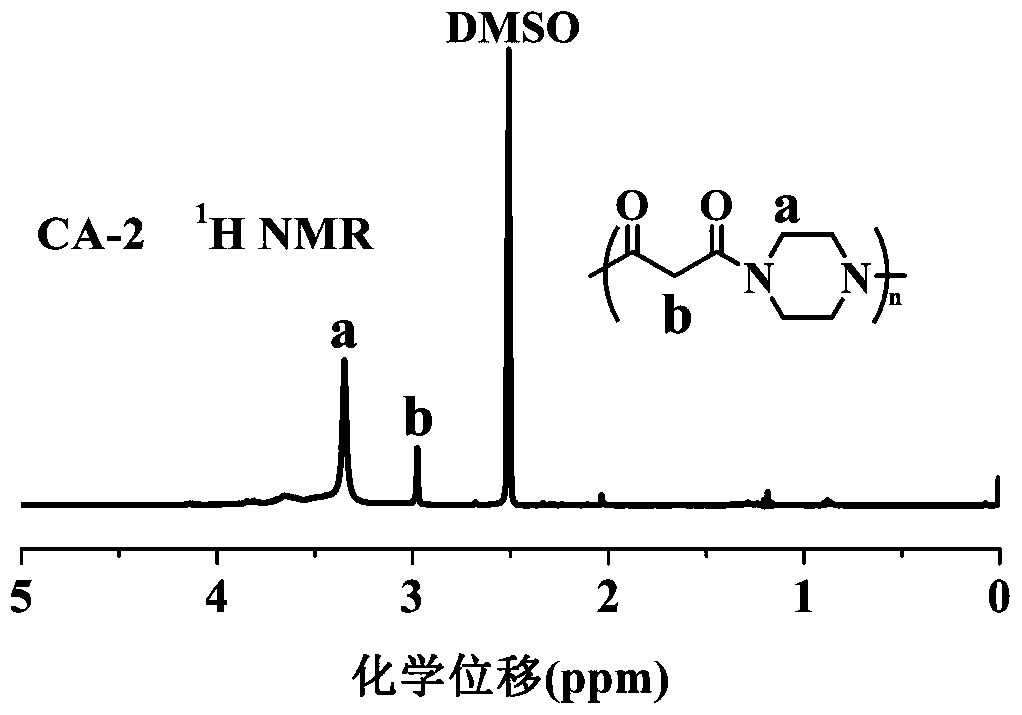

[0038] Add 1 mol of malonyl chloride to 1L of 1,4-dioxane to disperse it evenly, and record it as liquid A; then add 0.95 mol of anhydrous piperazine and 2.1 mol of triethylamine acid-binding agent to Add it into 500mL of 1,4-dioxane to disperse it evenly, record it as liquid B, then drop liquid B into liquid A while stirring at 40°C, raise the temperature to 100°C after the dropwise addition, and react for 8 hours That's it. After the reaction is completed, remove 1,4-dioxane, add ethanol to the remaining solid, stir and beat, then suction filter, repeat this process at least 3 times, collect the solid, and dry it to obtain charcoal agent CA-2.

Embodiment 3

[0040] Add 1mol of succinyl chloride into 1L of chloroform to make it evenly dispersed, and record it as liquid A; then add 0.95mol of anhydrous piperazine and 2.1mol of triethylamine acid-binding agent to 500mL of chloroform to make If the dispersion is uniform, it is recorded as liquid B, and then liquid B is dripped into liquid A while stirring at 0°C. After the dropwise addition, the temperature is raised to 60°C, and the reaction is done for 12 hours. After the reaction is completed, remove the chloroform, add ethanol to the remaining solid, stir and make a slurry, then suction filter, repeat this process at least 3 times, collect the solid, and dry it to obtain the charcoal agent CA-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com