Patents

Literature

42results about How to "No "blooming" phenomenon" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-hardness extruded silicone rubber composition and preparation method thereof

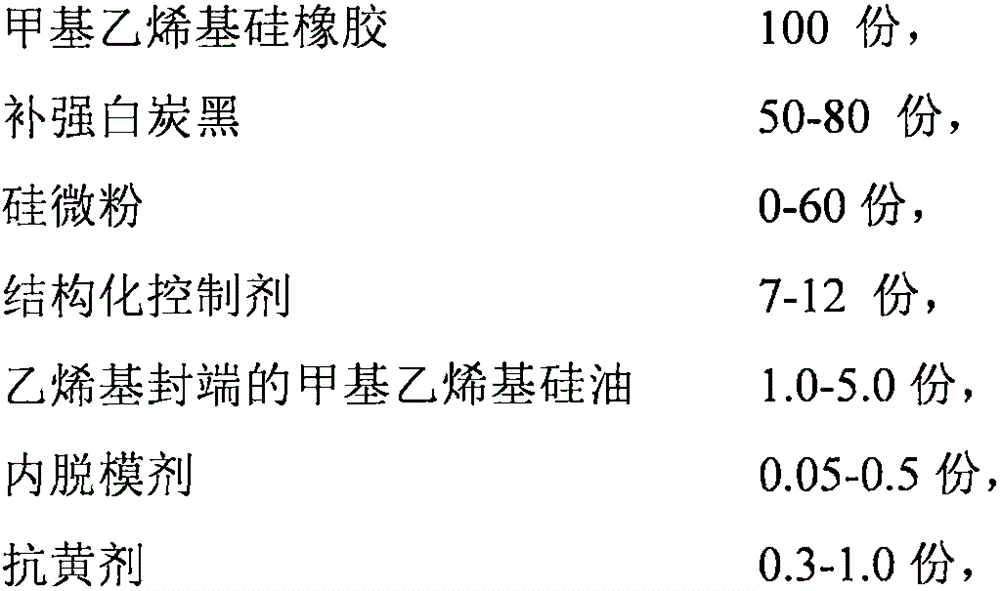

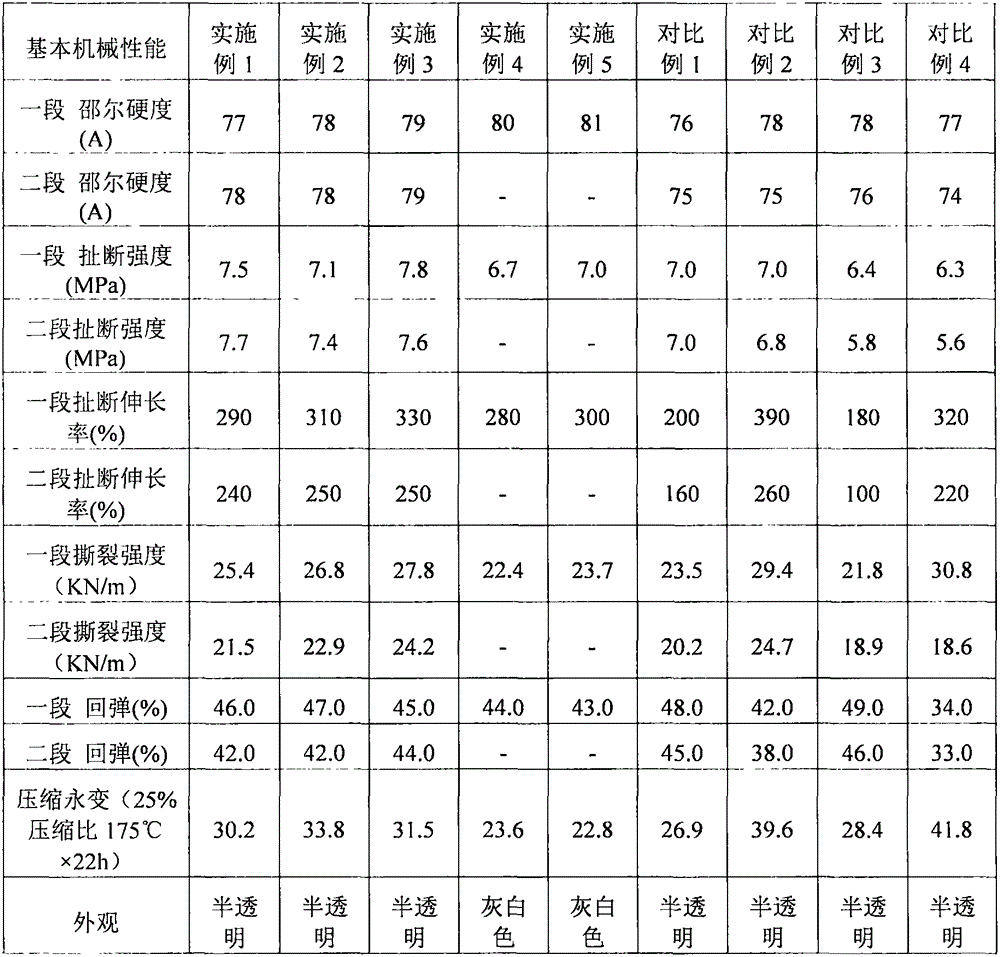

The invention provides high-hardness extruded silicone rubber composition. The silicone rubber takes methyl vinyl siloxane with the average molecular weight of 0.55-0.75 million and the average vinyl molar content of 0.4-0.55% as rubber master batch, and reinforced white carbon black, silica powder, a structurized control agent, vinyl-terminated methyl vinyl silicone oil, an internal releasing agent, an anti-yellowing agent, magnesium oxide and cerium oxide are added. The prepared silicone rubber has high hardness, high resilience, relatively high elongation and high tear resistance after high temperature vulcanization and can be applicable to silicone products such as an industrial rubber-covered roller, a pressing wheel, a sealing ring and a sealing element.

Owner:ZHEJIANG XINAN CHEM INDAL GROUP

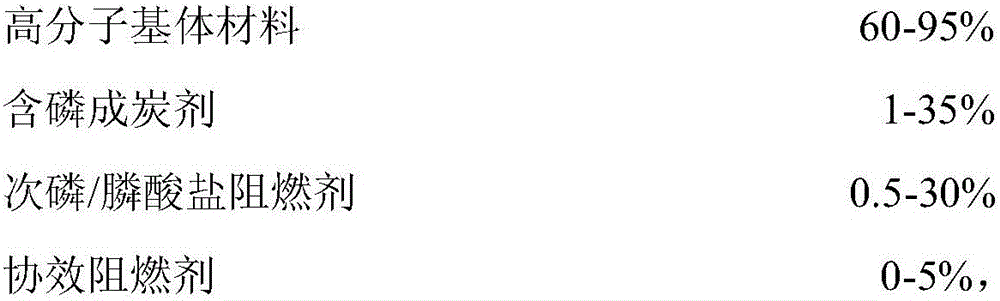

Flame-retardant high polymer material based on compounding of phosphorus containing char-forming agents and hypophosphite/phosphonate

ActiveCN106496729AHigh flame retardant efficiencyGood char formationPolymer scienceLimiting oxygen index

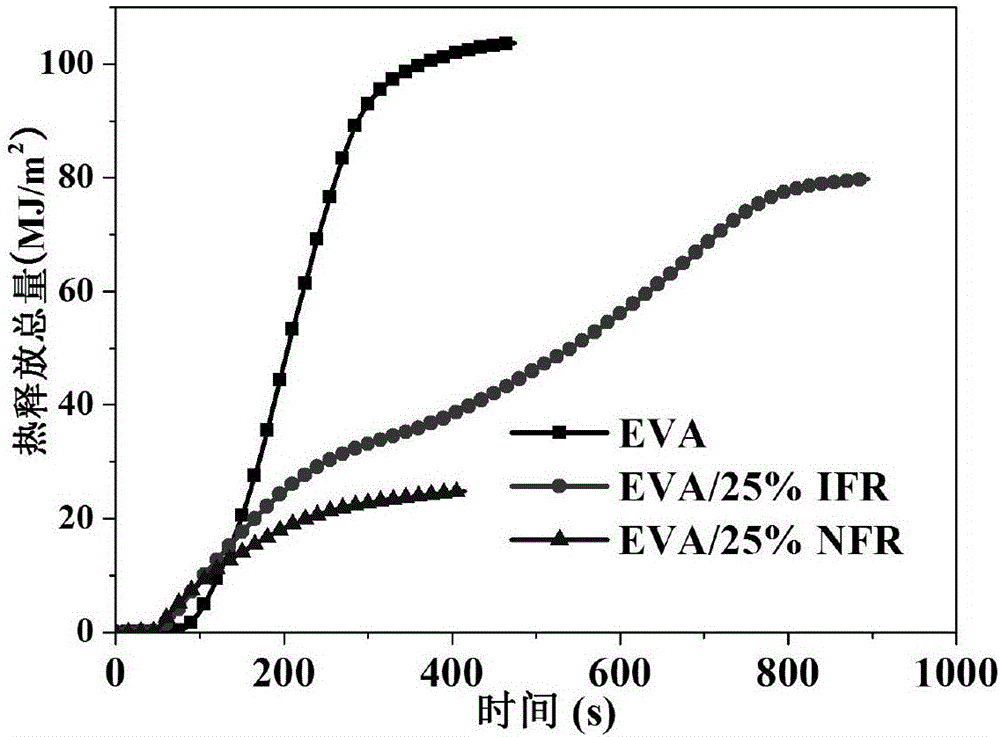

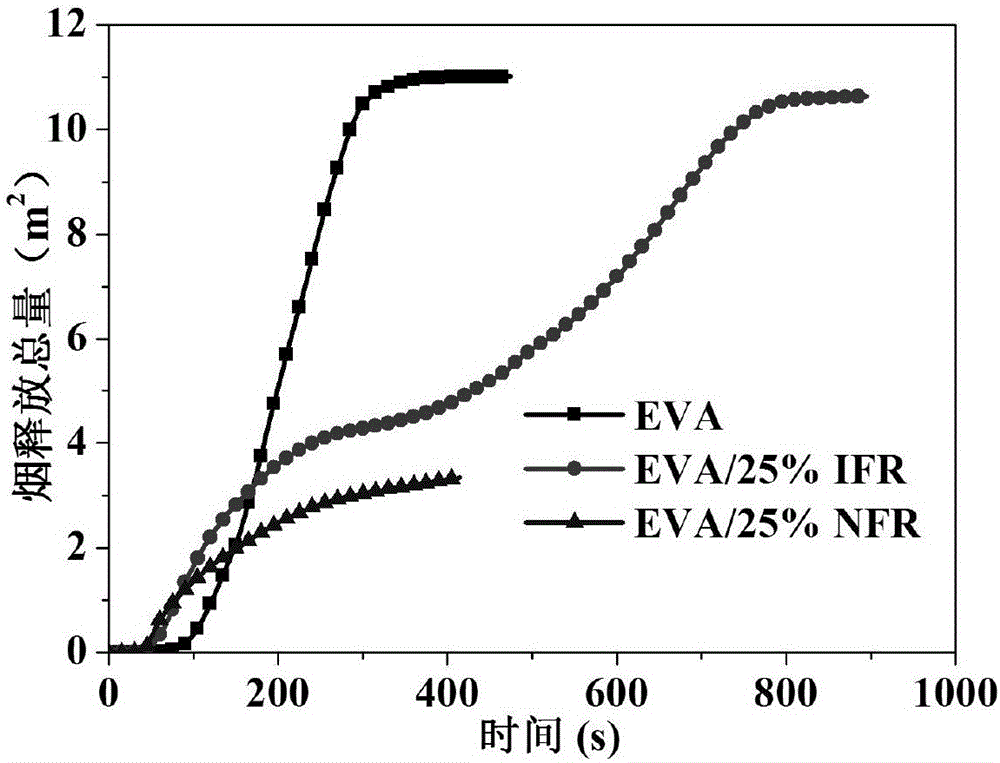

The invention discloses a flame-retardant high polymer material based on compounding of phosphorus containing char-forming agents and hypophosphite / phosphonate. The flame-retardant high polymer material is formed by blending, in weight percentage, 60-95% of high polymer base materials, 1-35% of phosphorus containing char-forming agents, 0.5-30% of hypophosphite / phosphonate and 0-5% of synergistic flame retardants. The compound main flame retardants used in the material have double char-forming functions, the material has excellent flame-retardant and smoke suppression properties, limit oxygen index reaches up to 27.0-49.5%, vertical burning test level ranges from UL-94V-1 to V-0, the total heat release of the material in cone calorimeter is reduced by 48.2-90.5% as compared with that of a pure base material, and total smoke release is reduced by 41.6-88.5%. Besides, the flame retardants used in the flame-retardant high polymer material have excellent water resistance, so that the material also has excellent water resistance, after the material is soaked in 70 DEG C for 168 hours and then dried, the vertical burning test level is unchanged, and the oxygen index is only reduced by 0-0.5%.

Owner:SICHUAN UNIV

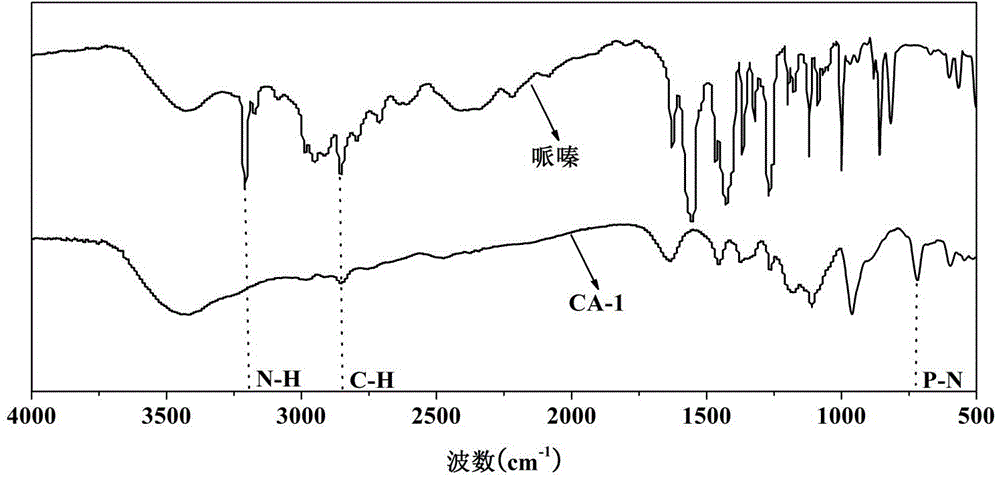

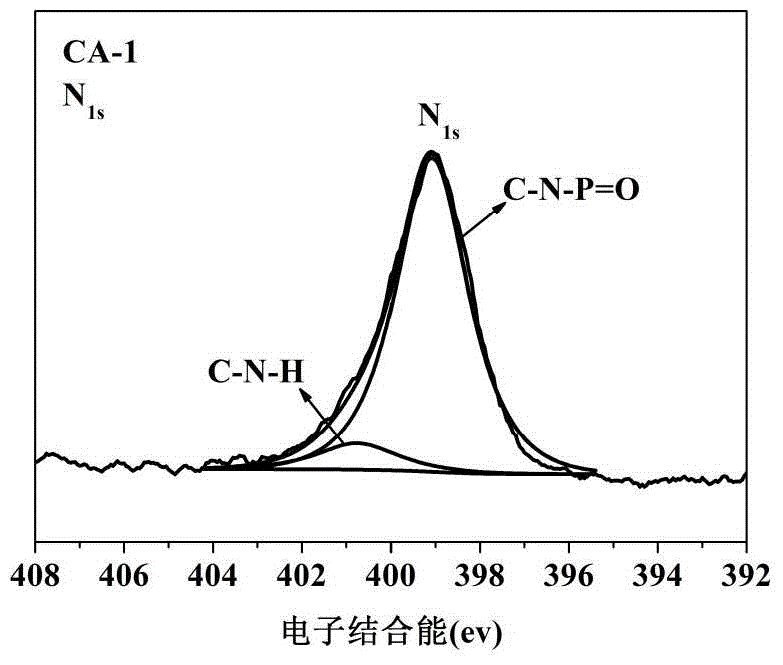

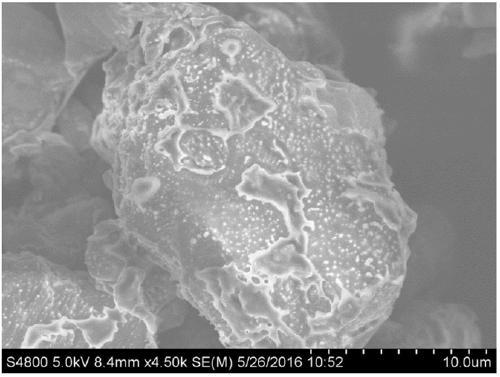

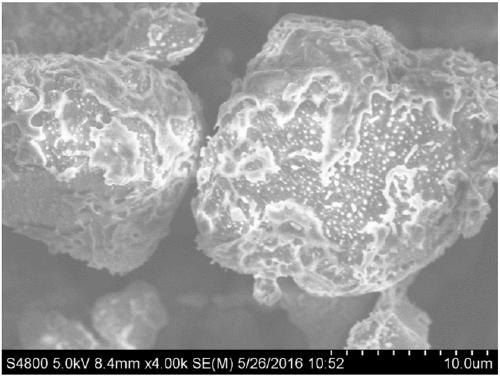

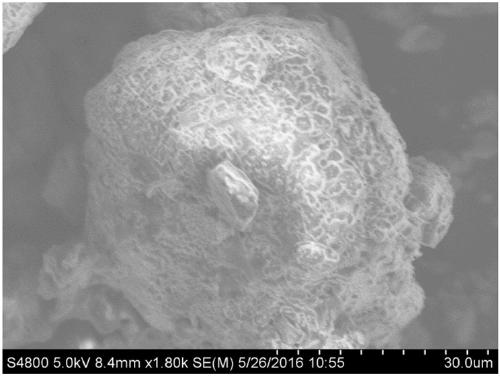

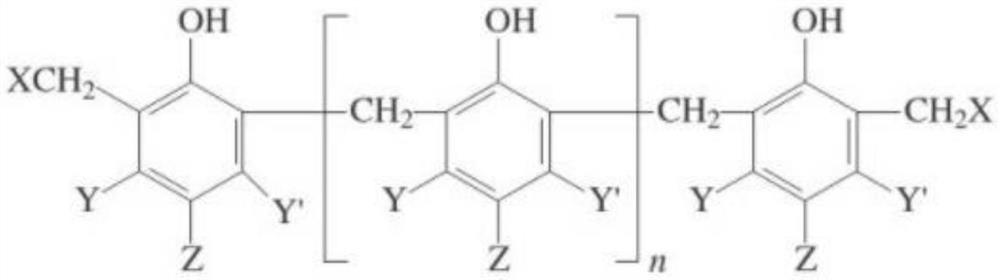

Phosphorus-containing macromolecular intumescent flame-retardant charring agent with cross-linked structure as well as preparation method and application thereof

ActiveCN104559204ASolve the problems caused by poor water resistanceImprove solubilityEpoxyCross-link

The invention discloses a phosphorus-containing macromolecular intumescent flame-retardant charring agent with a cross-linked structure as well as a preparation method and an application thereof. A structural general formula of the phosphorus-containing macromolecular intumescent flame-retardant charring agent is as shown in the specification, wherein X, Y and Z are any one of diamine, diol group, alkylol amine or diphenol, and can be the same, and can also be different. The invention further relates to a preparation method of the flame-retardant charring agent, and an application of the flame-retardant charring agent as a carbon source of a novel intumescent flame-retardant system, and an application of novel intumescent flame-retardant system in polyolefin, polyurethane, polylactic acid, polyamide and epoxy resin. The intumescent flame-retardant charring agent prepared by the method has good charring property, and is free of halogen, low in toxicity and high in water resistance, good in compatibility with a plurality of flame-retardant high polymers, relatively small in effects on mechanical property, simple in synthesis process, easy to control, and easy to put into industrial production.

Owner:SICHUAN UNIV

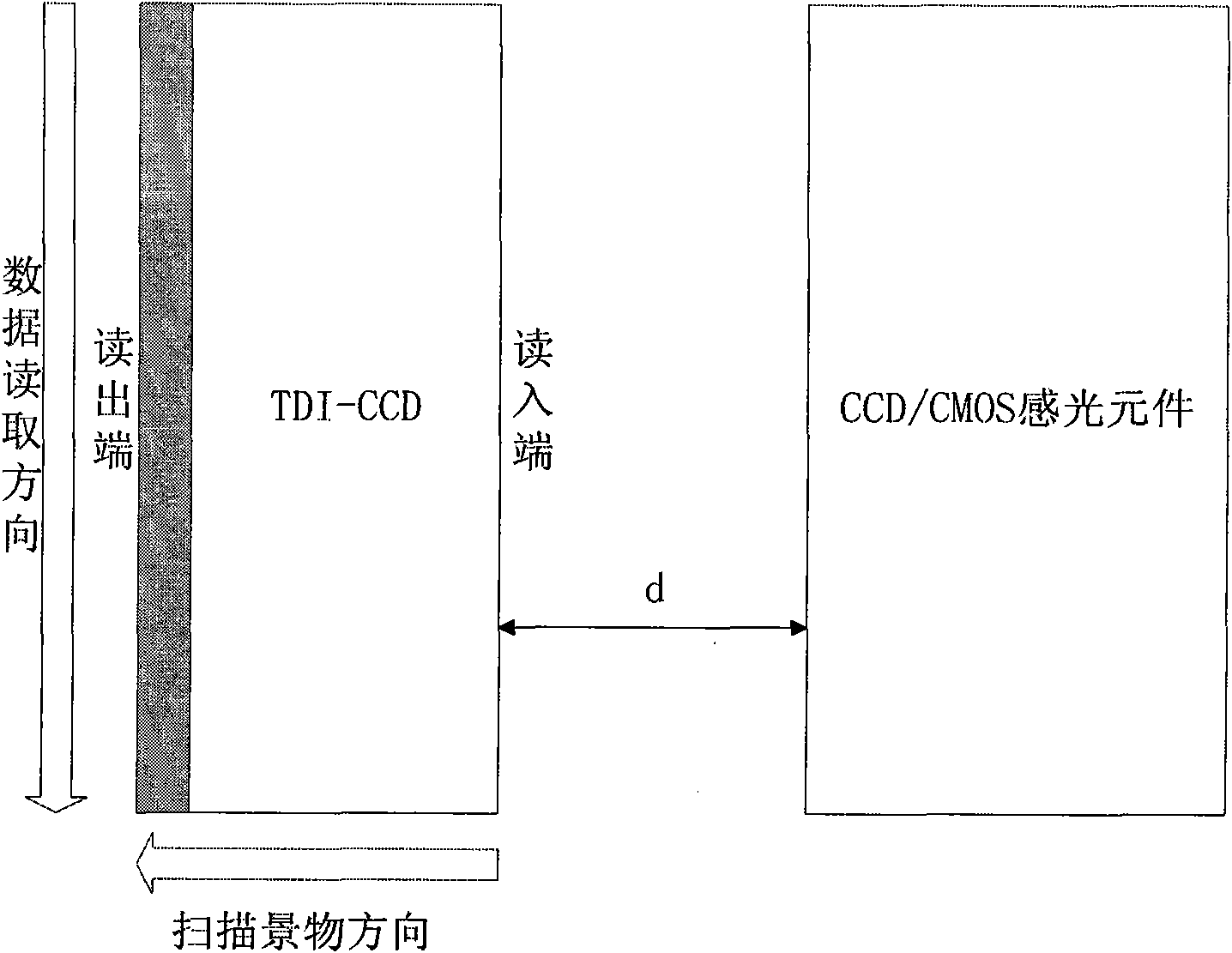

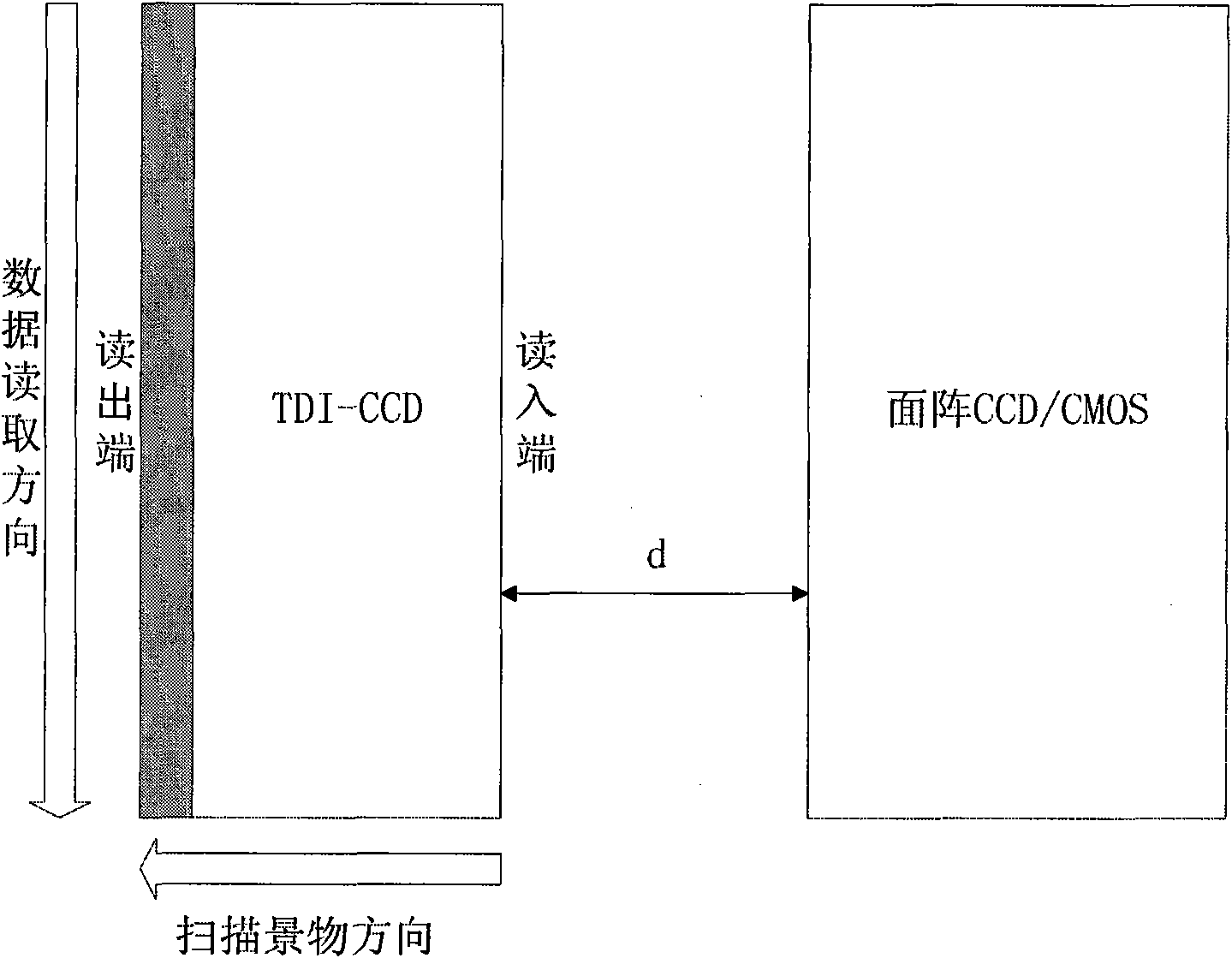

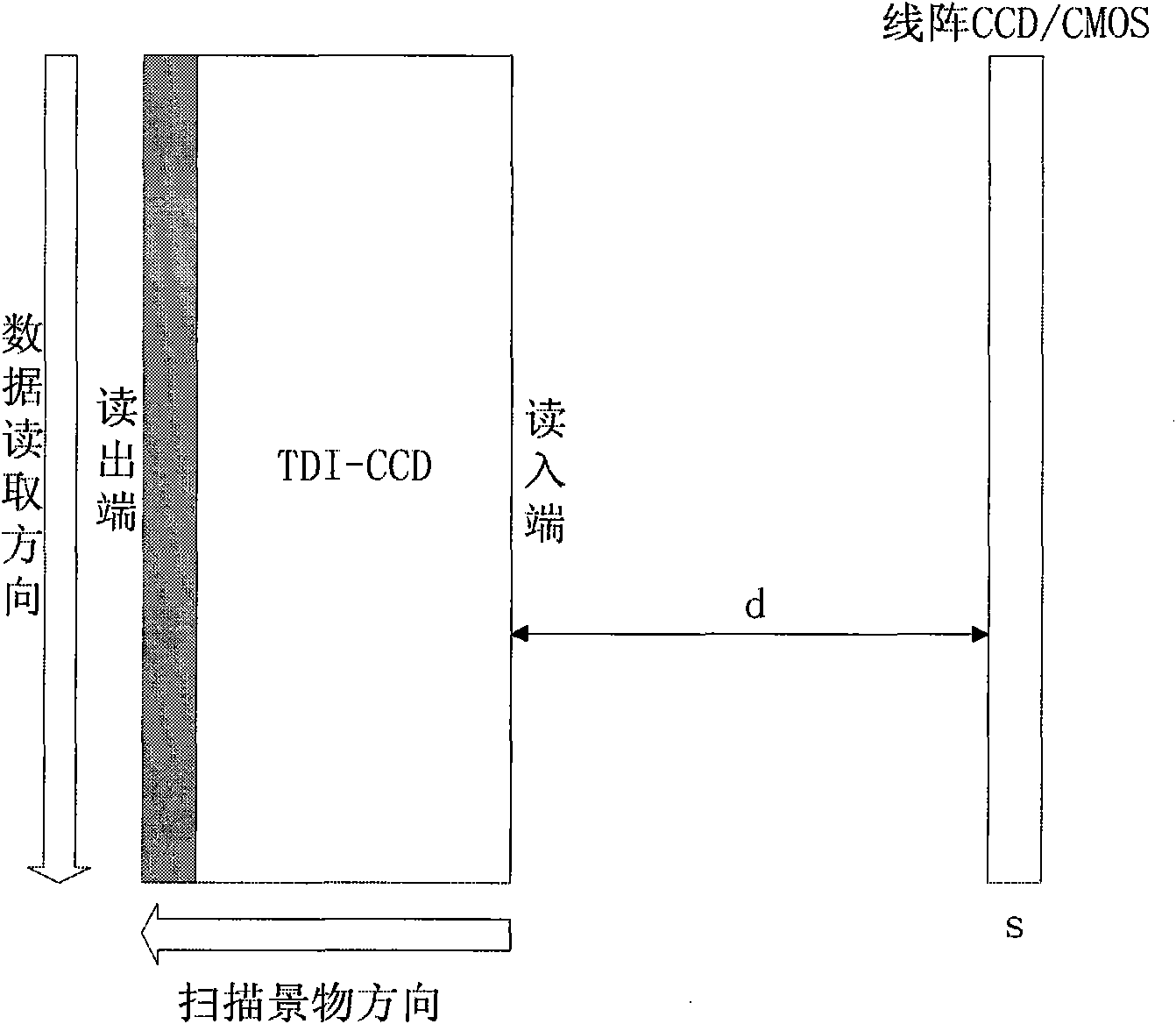

Method and device for obtaining image based on dynamic time delay integral

InactiveCN101635782ANo lossLow costTelevision system detailsTelevision system scanning detailsCMOSSignal-to-noise ratio (imaging)

The invention relates to a method and a device for obtaining an image based on the dynamic time delay integral. A CCD / CMOS photosensitive element and a TDI-CCD form an image obtainer, the integral time of TDI-CCD is controlled by analyzing an image read by the CCD / CMOS photosensitive element, and the image is read out before the image does not perform Blooming, finally the image is processed to obtain a scene image. In the invention, the integral time of the TDI-CCD is controlled according to the practical situation of the scene image, and the image is read out before the image does not perform Blooming so that the image quality loss is prevented, the integral time of the TDI-CCD is ensured in maximum, the advantage of long integral time of the TDI-CCD is greatly reserved, and the obtained image and the light intensity of a scene are a direct proportion relationship; therefore, the method and the device can prevent the image from generating Blooming phenomenon, ensure the image not to be distorted, and improve the signal-to-noise ratio of the image.

Owner:NANJING UNIV

Joint glue for corner part of sealing strip for car door and preparation method

The invention discloses joint glue for a corner part of a sealing strip for a car door and a preparation method. The joint glue adopts the technical scheme that the joint glue is prepared by the following materials in parts by mass: 100-160 parts of ethylene propylene diene terpolymer rubber K4869, 20-50 parts of ethylene propylene diene terpolymer rubber 4045M, 3-8 parts of zinc oxide, 1-3 parts of stearic acid, 1-3 parts of dispersant L-24, 2-5 parts of polyethylene glycol, 60-100 parts of FEF (Fast Extruding Furnace) level carbon black N550, 20-80 parts of light calcium carbonate, 40-70 parts of paraffin oil, 3-8 parts of moisture absorbent, 0.1-0.5 parts of anti-scorching agent, 0.8-1.6 parts of sulfur and 1.7-4.7 parts of accelerant. The mooney viscosity of the joint glue is increased to be 16; the tensile strength is improved to be 12.3MPa; a shearing force during mixing is increased obviously; the dispersity of a packing is improved; skidding during the mixing of the glue is precluded; and the production efficiency is improved.

Owner:GREAT WALL MOTOR CO LTD

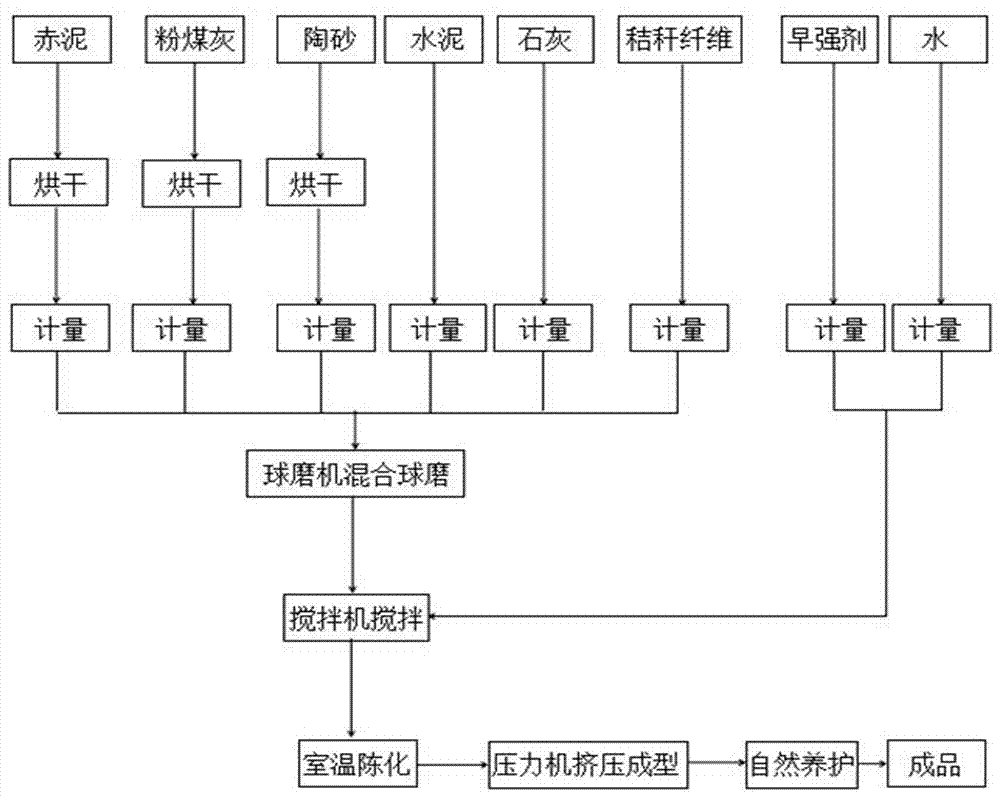

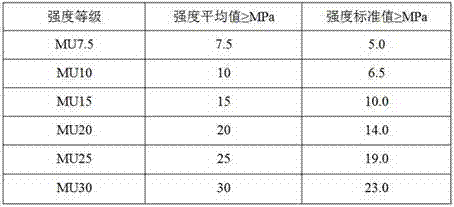

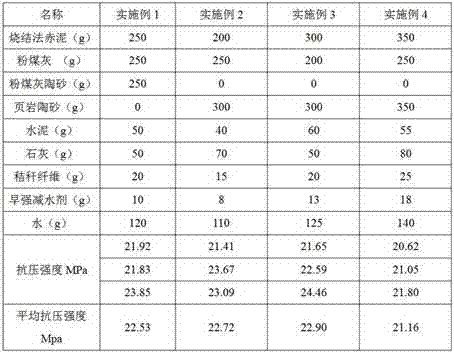

Red-mud-fly-ash high-strength heat-preservation building block based on alkali excitation and preparation method thereof

The invention discloses a red-mud-fly-ash high-strength heat-preservation building block based on alkali excitation. Industrial waste fly ash and red mud serve as main raw materials, cement and quicklime serve as auxiliary materials, and fly-ash pottery sand or shale pottery sand serve as heat-preservation materials. The building block is prepared from, by mass, 18-40% of red mud, 18-30% of fly ash, 25-40% of pottery sand, 3-8% of cement, 3-10% of lime, 1-3% of straw fibers and 0.5-2% of early strength agents, the water content is 10-15%, aging is conducted for 8-36 hours, and molding is conducted under the pressure of 40 MPa; the building block is prepared by the steps of drying, grinding, weighing, mixing of the auxiliary materials, compression molding, standard maintenance and natural curing. The red-mud-fly-ash high-strength heat-preservation building block based on the alkali excitation has the advantages of being simple in molding process, capable of having a reaction and being cured quickly at room temperature, and free from sintering and stream-pressure, products of the building block are high in compressive strength and anti-dry-shrinkage performance and good in impermeability, and can be stored for a long time without scumming phenomena. A large amount of industrial waste can be utilized, the energy and resources are saved, and the cost and energy consumption are low.

Owner:HUNAN YUNZHONG REGENERATION TECH CO LTD

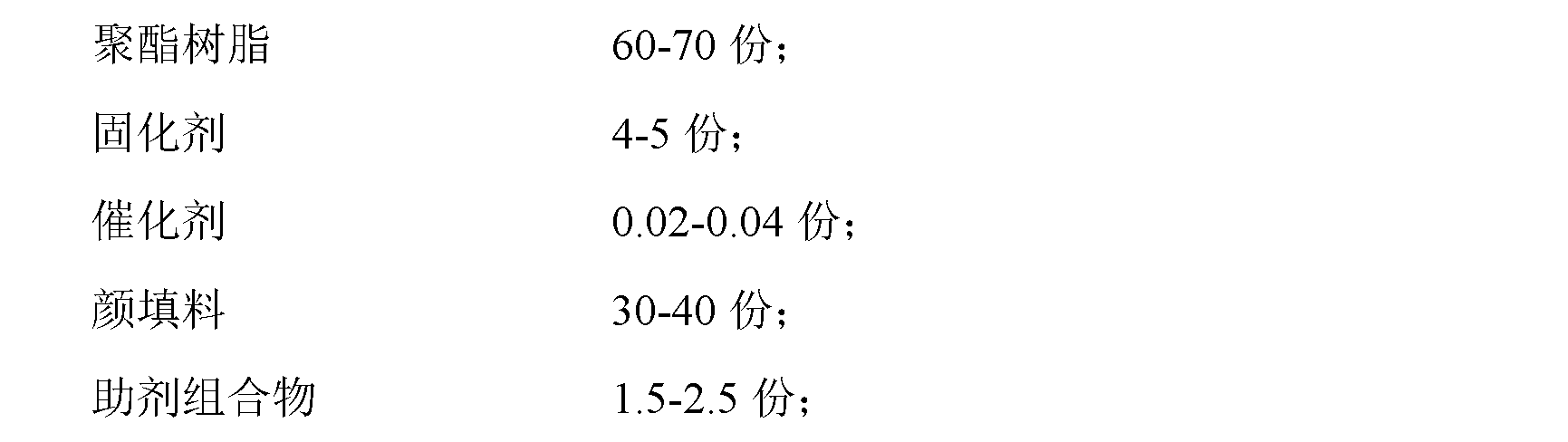

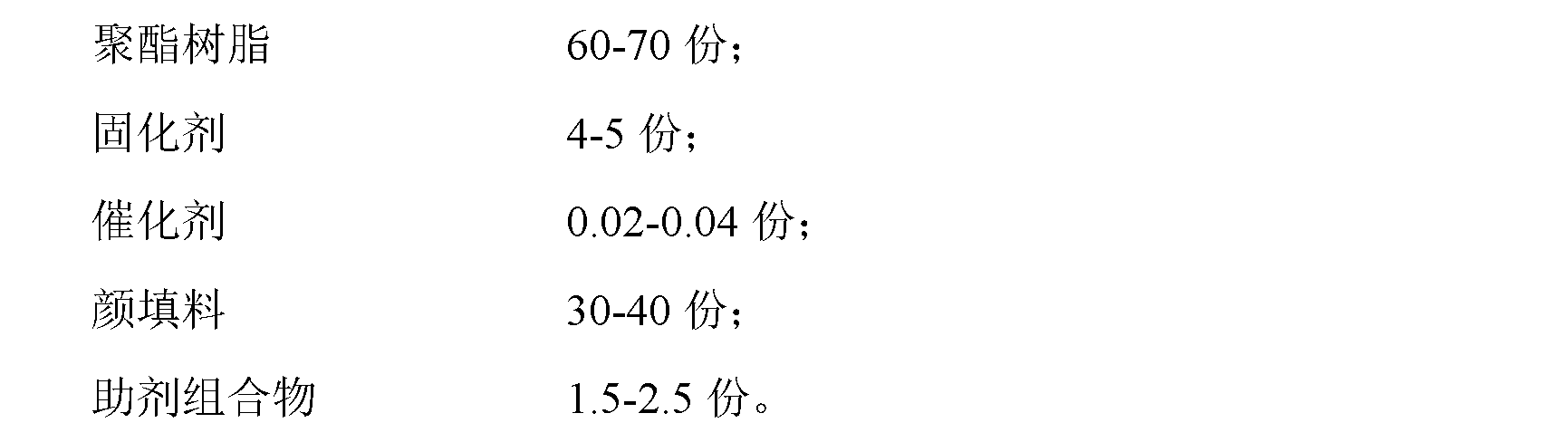

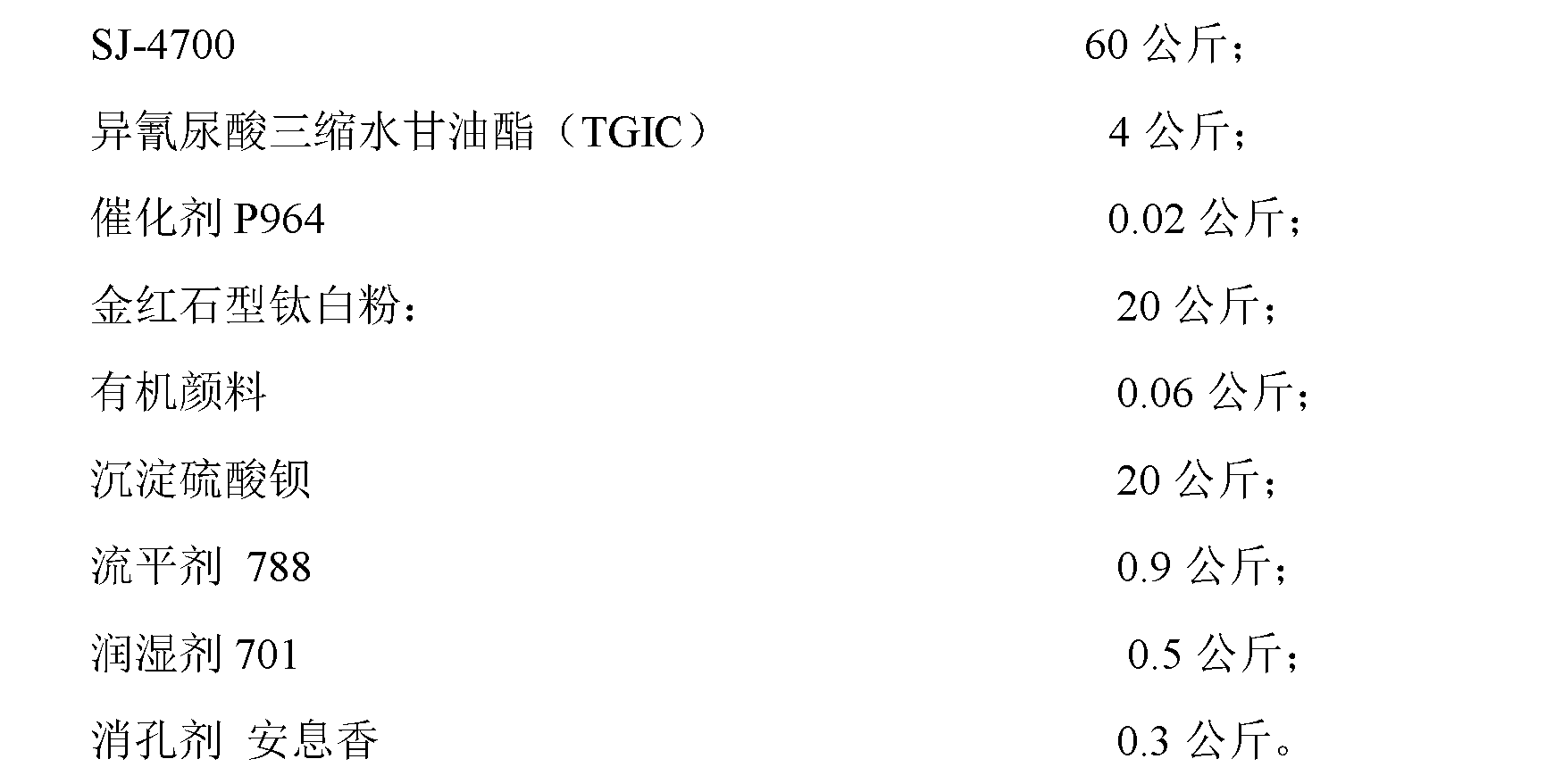

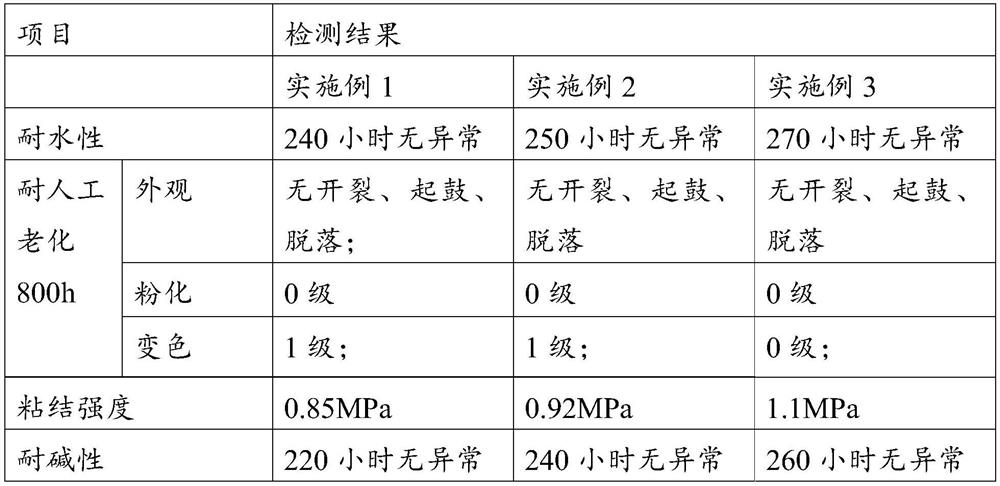

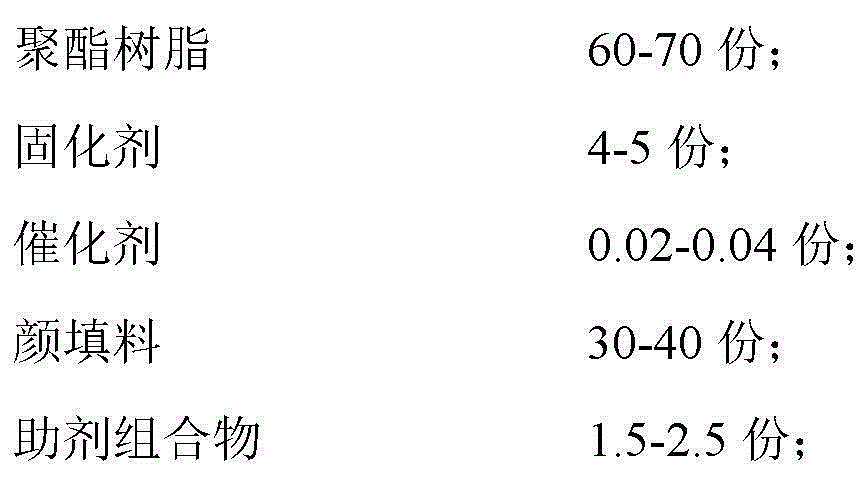

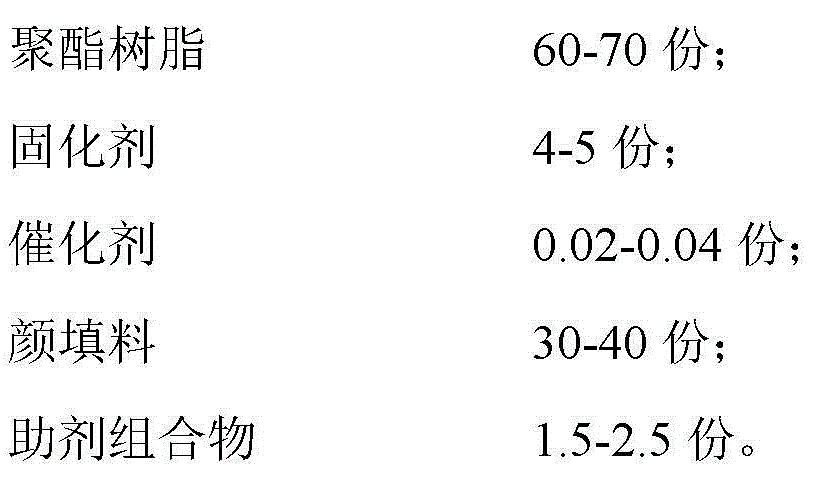

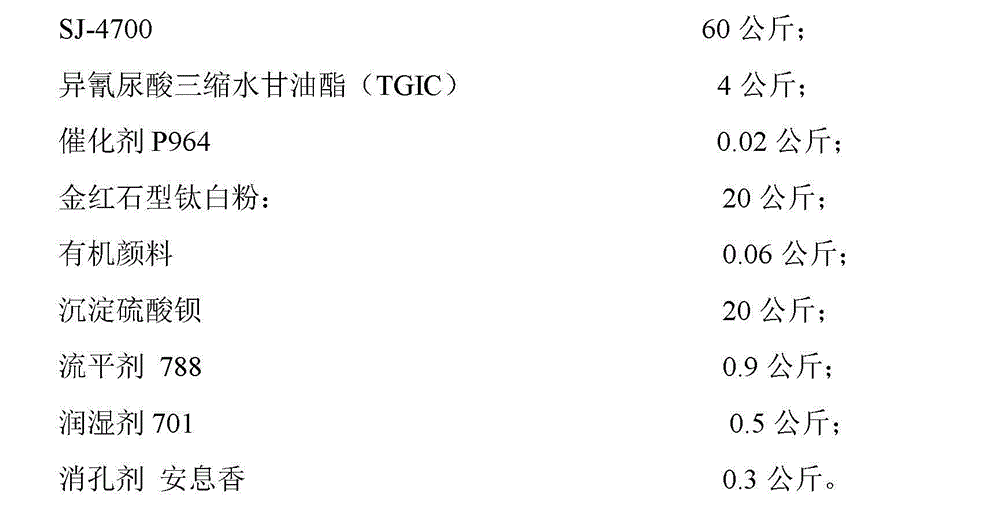

Powder coating for vacuum coating and bottom layer of metal substrate and preparation method of powder coating

InactiveCN103265878AImprove anti-corrosion performanceImprove adhesionAnti-corrosive paintsPolyurea/polyurethane coatingsLow temperature curingPolyester resin

The invention relates to a powder coating for a vacuum coating and a bottom layer of a metal substrate. The powder coating comprises the following components in parts by weight: 60-70 parts of polyester resin, 4-5 parts of curing agent, 0.02-0.04 part of catalyst, 30-40 parts of pigment and filler and 1.5-2.5 parts of additive composition. The powder coating has excellent antiseptic property and super adhesive force with liquid pain, does not give off small molecules, has no influence on the adhesive force of the vacuum coating and the bottom layer and provides a guarantee for firmly attaching the vacuum coating to a liquid paint film; and meanwhile, the powder coating has the advantages of being environment-friendly and energy-saving, realizing the low-temperature curing, having excellent anti-corrosive property, good specular reflection effect, fine and smooth surface, very good decorative effect, excellent day lighting property and excellent quality, being capable of ensuring the high brightness of the vacuum coating and having no phenomena of falling and flooding and can be used for spraying the substrate before the liquid paint is sprayed on the vacuum coating of the metal substrate.

Owner:TIANJIN XIANGSHENG NEW MATERIALS CO LTD

Preparation method for non-blooming natural rubber gloves

The invention relates to a preparation method for non-blooming natural rubber gloves. The method comprises the following steps: step 1, preparing pre-vulcanized natural latex: mixing 2-8 parts by weight of a first vulcanizing agent, 0.5-4 parts by weight of a second vulcanizing agent and 0.5-2 parts by weight of a vulcanization accelerant into 90-120 parts by weight of natural latex, performing pre-vulcanization at temperature of 40-80 DEG C for 1-10 h, and performing normal-temperature placing, wherein the first vulcanizing agent is a resin vulcanizing agent, and the second vulcanizing agentis a thiuram or a triazine sodium salt; step 2, preparing impregnating rubber slurry: taking 90-120 parts by weight of the pre-vulcanized natural latex prepared in the step 1, mixing the taken pre-vulcanized natural latex and 0.5-1.5 parts by weight of an active agent, and performing adjustment to predetermined viscosity by adding a thickening agent; step 3, performing gum impregnation on glove blanks: impregnating the glove blanks into the impregnating rubber slurry prepared in the step 2; and step 4, performing vulcanizing drying: preparing the non-blooming natural rubber gloves. According to the method provided by the invention, the natural rubber gloves prepared by the method have no blooming phenomena when being placed indoors for one year, and the EN388 test level reaches 3141.

Owner:SHANDONG XINGYU GLOVES

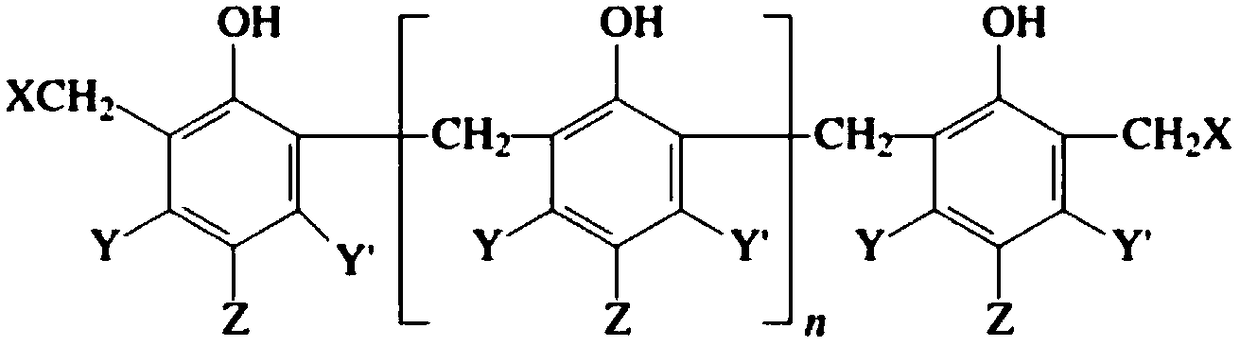

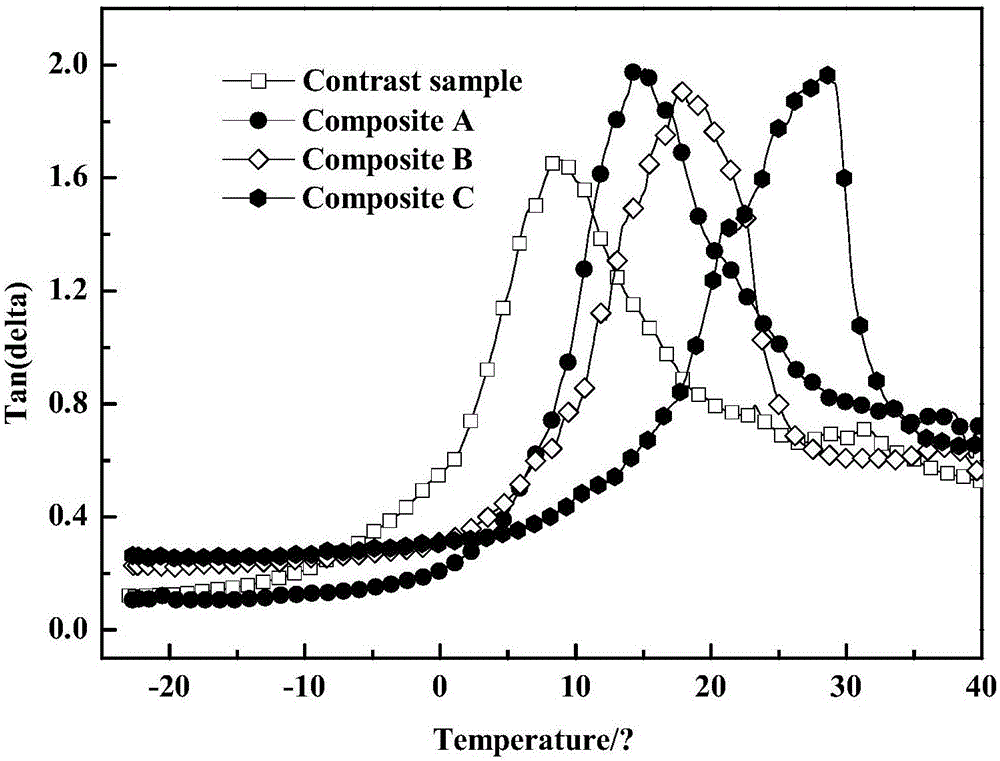

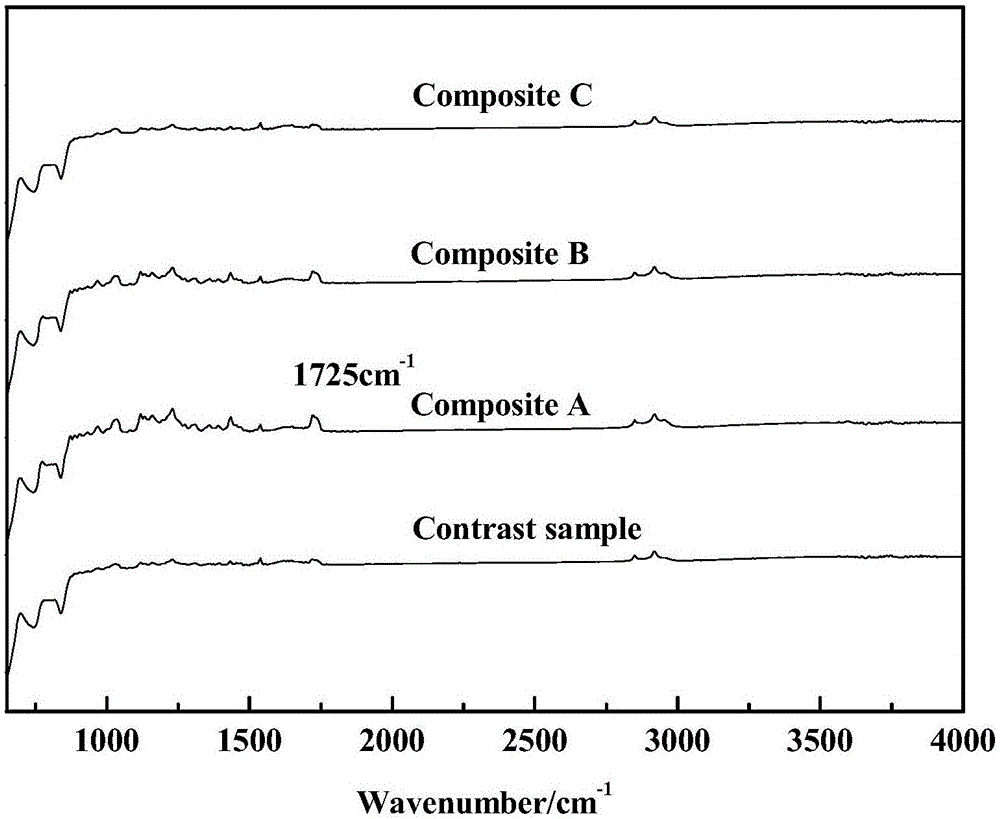

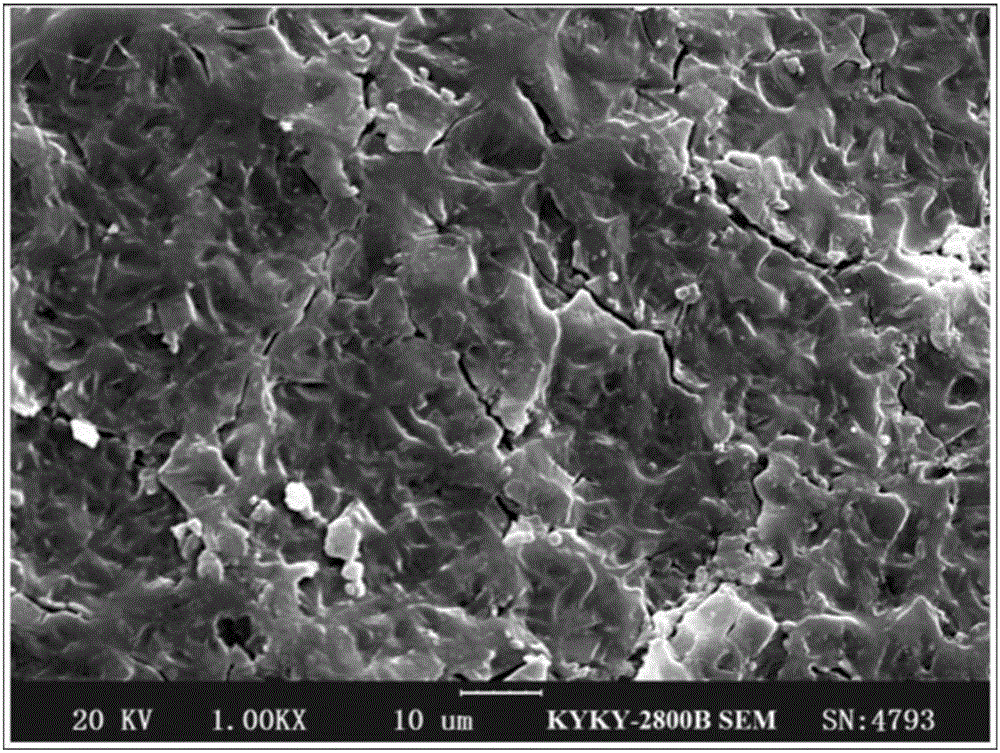

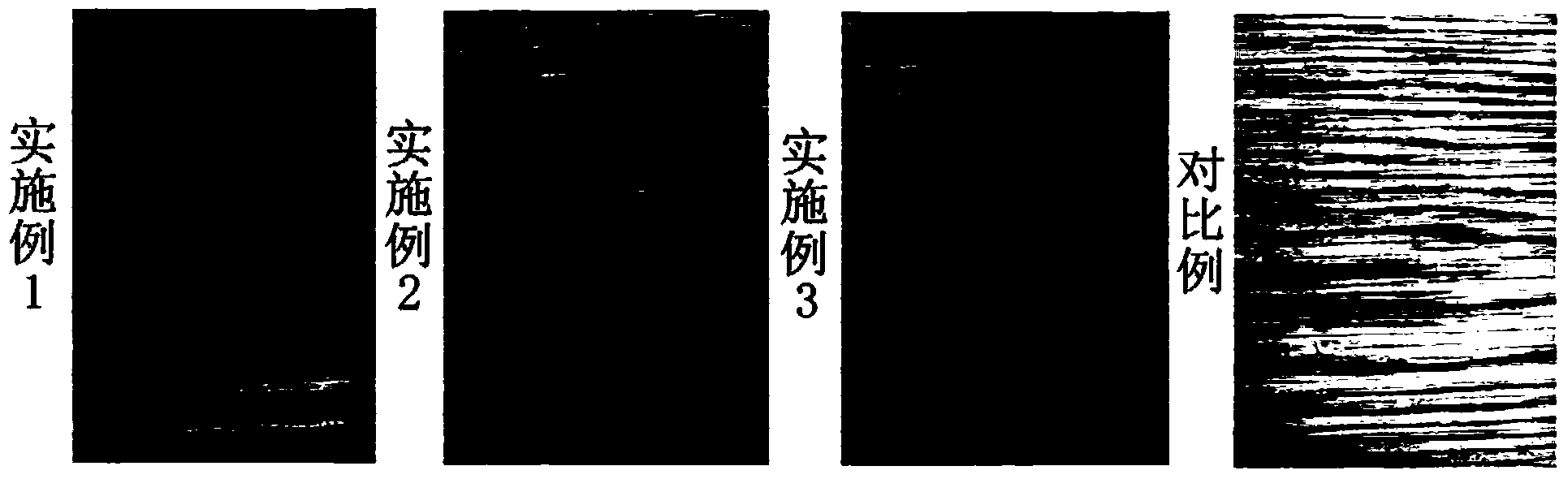

Damping vibration attenuation composite material containing nanocrystalline and manufacturing method thereof

InactiveCN106432847ALoss Factor Peak IncreaseNo "blooming" phenomenonVibration attenuationNitrile rubber

The invention discloses a damping vibration attenuation composite material containing nanocrystalline. The damping vibration attenuation composite material containing nanocrystalline includes carboxyl nitrile rubber, hindered phenol type antioxidant AO4426 and hindered phenol type antioxidant AO2246. A preparation method of the damping vibration attenuation composite material includes two steps: mixing and hot-pressing forming. Carboxyl nitrile rubber containing carboxyl function groups with strong polarity is adopted as a base material, dual-polarity functional organic micromolecules are added into the base material, and then the ester type damping composite material based on carboxy nitrile rubber is formed by mixing the materials evenly and conducting hot-pressing forming. An ester compound, which is formed by a dehydration reaction between OH of different organic micromolecules and carboxyl-COOH of carboxyl nitrile rubber in hot-pressing forming, is used as a matrix of the composite material, reversible hydrogen bonds are formed between a C=H group and OH of hindered phenol and between the C=H group and OH of organic micromolecules, therefore, the damping performance is effectively improved, the phenomenon of frost spraying does not occur in the use process, and the service life of the damping material is effectively prolonged.

Owner:IANGSU COLLEGE OF ENG & TECH

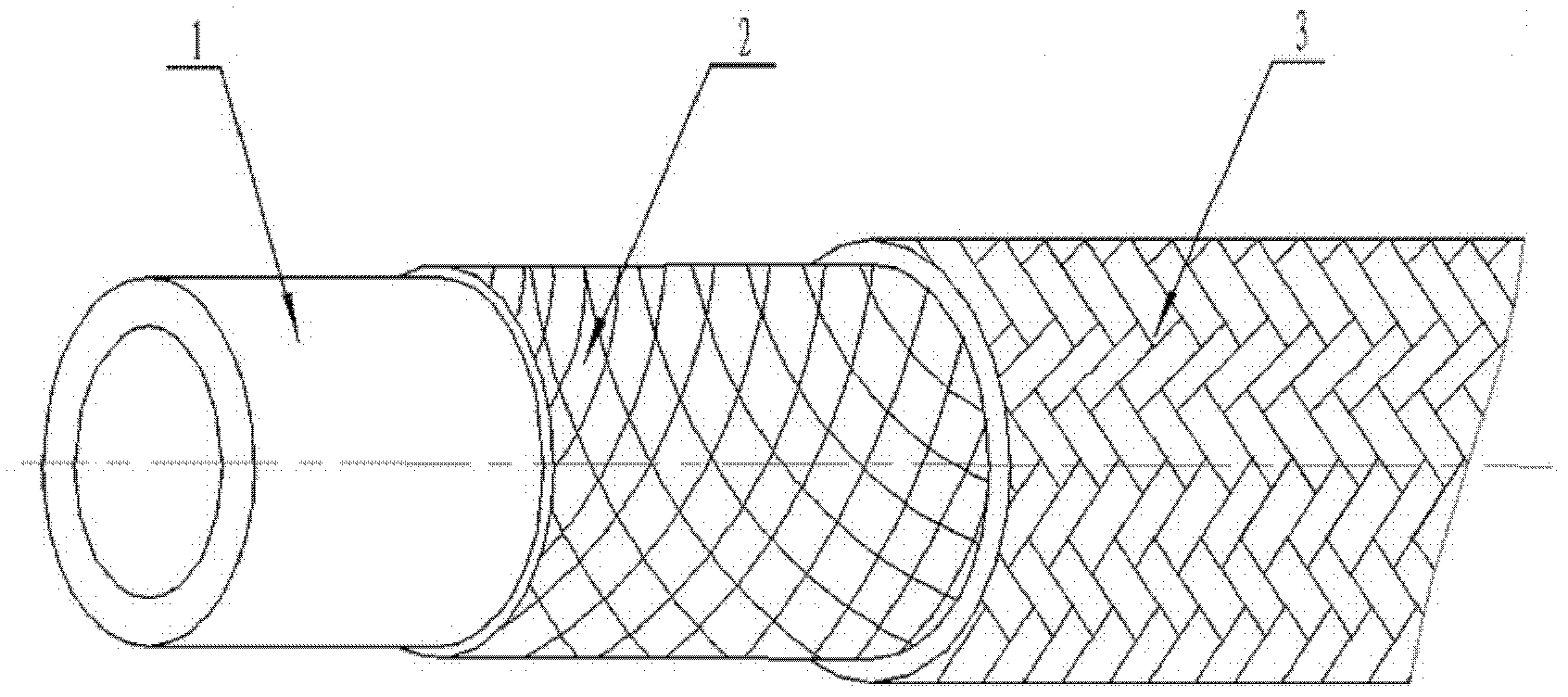

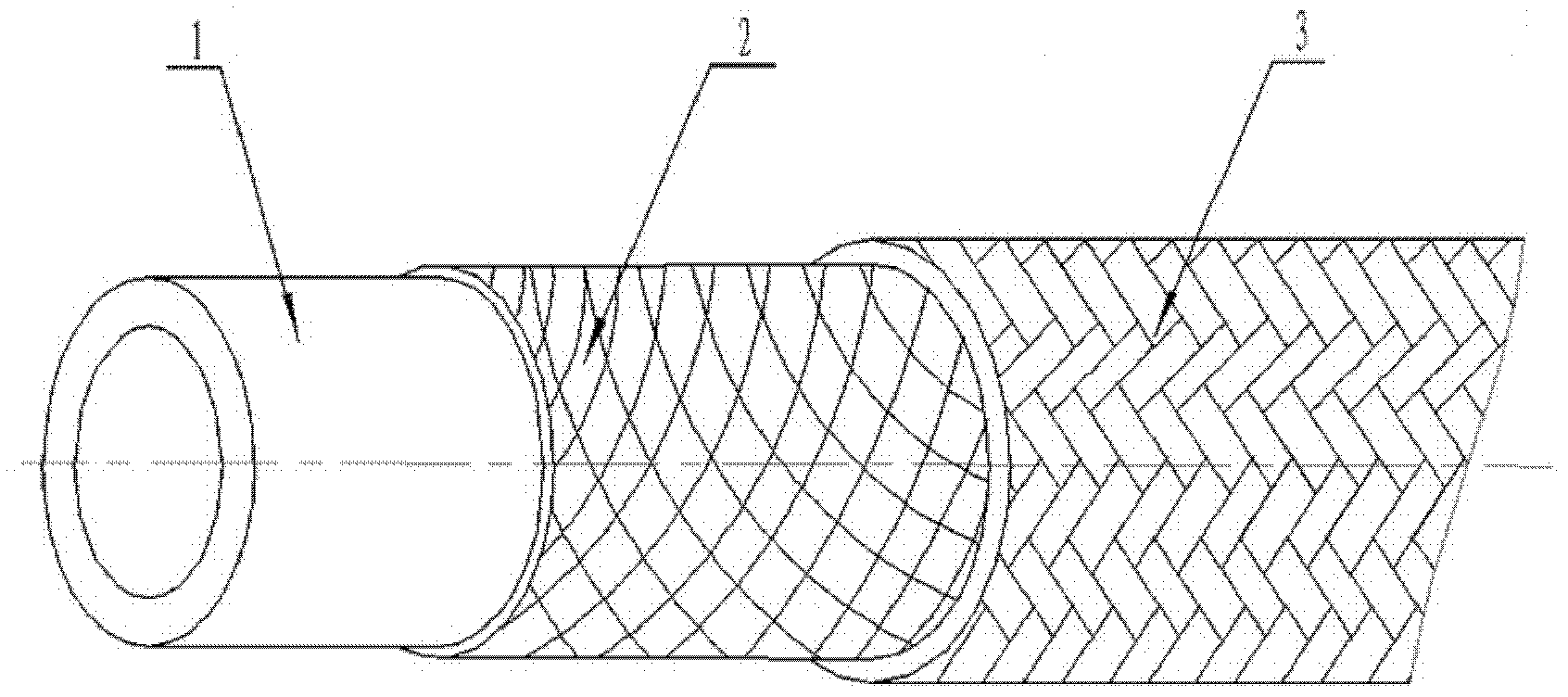

Automobile hose

The invention provides an automobile hose, comprising a rubber inner tube, wherein the rubber inner tube is covered by a stainless steel wire knitted sleeve layer and the stainless steel wire knitted sleeve layer is covered by a nylon wire knitted sleeve layer; rubber of the rubber inner tube is vulcanized and passes through knitting gaps of the stainless steel wire knitted sleeve layer to be adhered to the stainless steel wire knitted sleeve layer and the nylon wire knitted sleeve layer; the stainless steel wire knitted sleeve layer is embedded into the surface of the rubber inner tube, and the stainless steel wire knitted sleeve layer and the nylon wire knitted sleeve layer are adhered by the rubber of the rubber inner tube to form a whole body; and the covering rate of steel wires knitted on the surface of the rubber inner tube is 38-50%. The invention further provides a manufacturing method of the automobile hose. The automobile hose provided by the invention can bear higher work pressure and is flexible in tube body and lighter in weight; the inner tube, the stainless steel wires and the nylon wires are adhered to form a whole body, so that the work pressure is higher and the high-vacuum requirements for the use of racing automobiles can be met; and after the tube body is cut off, the phenomenon that the stainless steel wire knitted sleeve layer and the nylon wire knitted sleeve layer on the section of the hose are scattered does not happen, so that the automobile hose is suitable for being used as the hoses of the racing automobiles.

Owner:浙江铁马科技股份有限公司

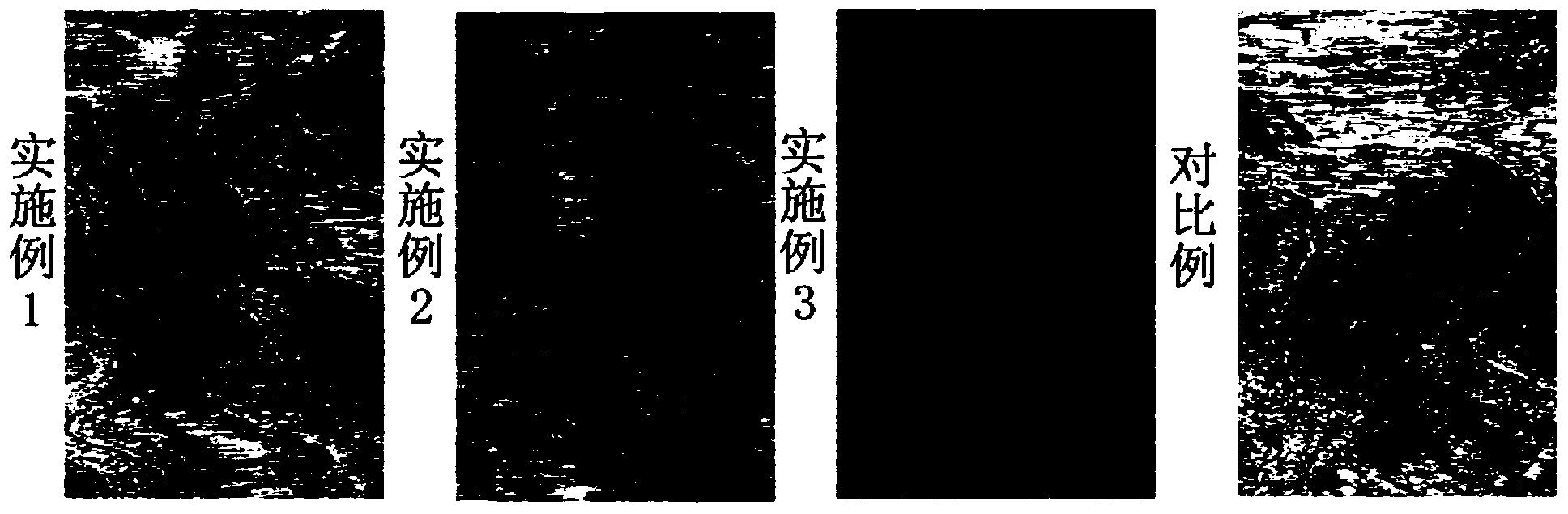

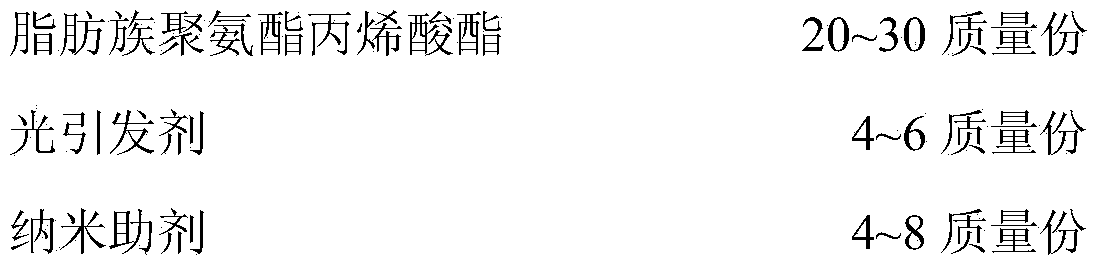

UV paint capable of realistically showing textures of coated timber body

InactiveCN104109459AImprove permeabilityStrong three-dimensional sensePolyurea/polyurethane coatingsSolid woodDiluent

The invention discloses a UV coating capable of realistically showing textures of a coated timber body. The UV paint comprises the following components in terms of 100 parts by mass: 20-30 parts by mass of aliphatic polyurethane acrylate, 4-6 parts by mass of a photoinitiator, 4-8 parts by mass of a nanometer additive, 0.5-1 part by mass of an adherence promoter, 0.3-0.5 part by mass of a wetting agent, 1-3 parts by mass of filling powder, 0.1-0.3 part by mass of a defoaming agent, 0.1-0.5 part by mass of a dispersant, 0.1-0.5 part by mass of an anti-settling agent and 0.3-2 parts by mass of an inhibitor and the balance of an active diluent. Experimental results show that since the UV paint provided by the invention has very good penetration capacity, textures of the timber body can be realistically shown and stabilized in a short time, the use requirements of the common wood species and the fast-growing wood species coated finished products for replacing rare solid wood boards can be met and the UV paint has significant market application values.

Owner:JETCOAT SHANGHAI CO LTD CHINA

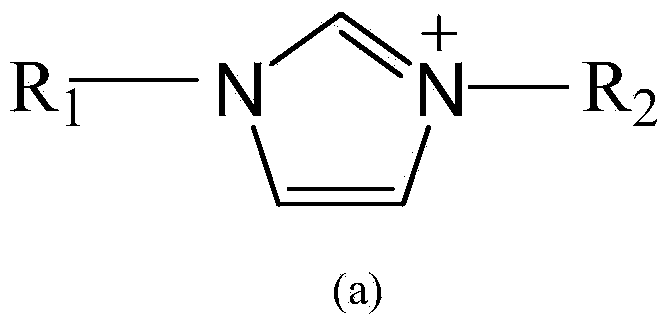

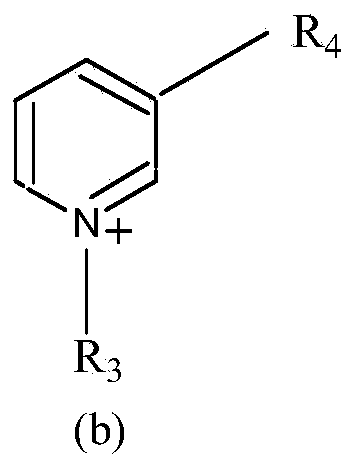

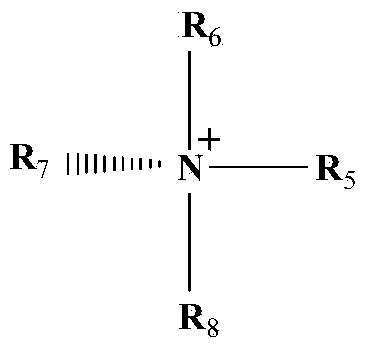

Application of ionic liquid in polyethylene terephthalate composite fiber

ActiveCN104073910AImprove antibacterial propertiesGood antibacterial effectNon-woven fabricsMonocomponent polyesters artificial filamentFiberPolyethylene terephthalate glycol

The invention discloses an application of an ionic liquid in polyethylene terephthalate composite fiber. The ionic liquid is taken as an antibiotic additive and applied to the polyethylene terephthalate composite fiber. The polyethylene terephthalate composite fiber with the added ionic liquid shows excellent inhibitory and bactericidal characteristics to staphylococcus aureus of gram-positive bacterium and escherichia coli of Gram-negative bacterium respectively. An antimicrobic polyethylene terephthalate composite fiber thin film provided by the invention can be applied to the fields of medical science, biology, environmental protection, spinning and the like.

Owner:ZHEJIANG JAVA SPECIALTY CHEM CO LTD

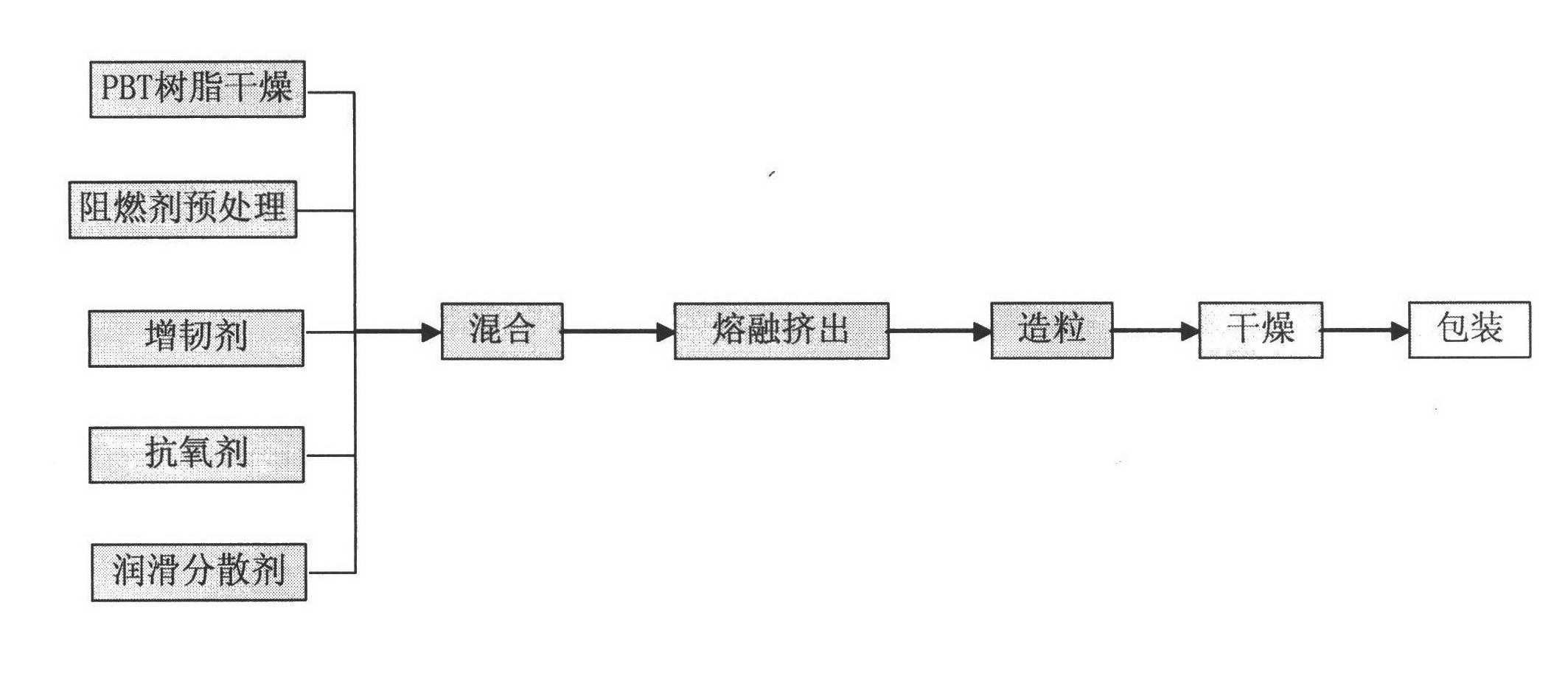

Halogen-free phosphorus-free flame-retarding toughening master batch special for PBT (polybutylene terephthalate) and preparation method thereof

InactiveCN102532830AImprove flame retardant performanceModification of the combustion processPolyethylene terephthalateAntioxidant

The invention provides a halogen-free phosphorus-free flame-retarding toughening master batch special for PBT (polybutylene terephthalate) and a preparation method thereof. The master batch is characterized in that the raw material formulation comprises the following components in percentage by weight: 20-60% of PBT resin, 70-35% of halogen-free phosphorus-free flame retardant, 5-10% of toughening agent, 0.2-0.6% of antioxidant, 1-3% of lubricating and dispersing agent and 0.2-1% of coupling agent. In the preparation method, PBT is used as a carrier, and PDPTP is used as the halogen-free phosphorus-free flame retardant; after surface treatment is carried out, the toughening agent, the dispersing agent and the antioxidant are added, and extrusion and granulation are carried out through two screws so as to prepare the halogen-free phosphorus-free flame-retarding toughening master batch special for PBT. According to the invention, the environment-friendly index of the prepared master batch meets the requirements of European Union RoHS (Restricted of Hazardous Substances), IEC (International Electrotechnical Commission) halogenation-free and Reach laws; and the prepared master batch can be used for modification of PBT, thus the flame-retarding grade of PBT reaches American UL 940.8mm V-0 grade, the CTI (comparative cracking index) value reaches more than 425V, the glowing filament experiment temperature reaches 750 DEG C but firing is not generated, and match color is not influenced.

Owner:SUZHOU CUIZHI NEW TECH DEV

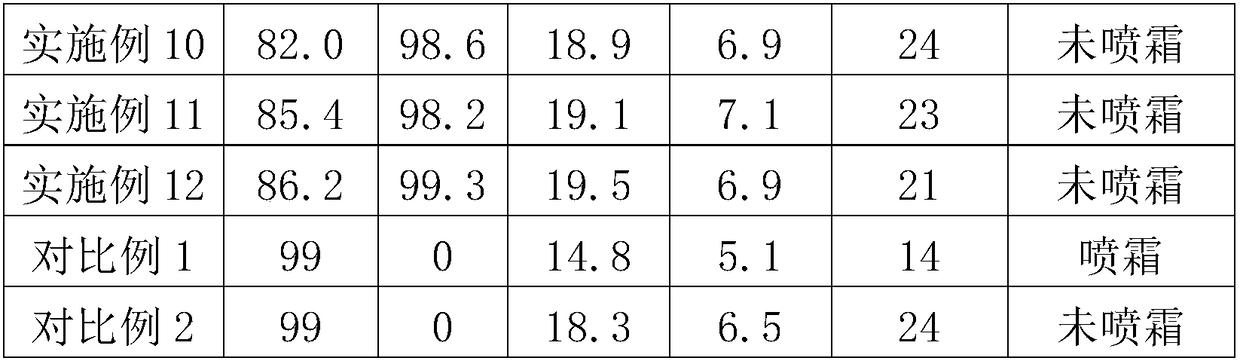

Precipitate-free flame retardant masterbatch

The invention discloses a precipitate-free flame retardant masterbatch, which comprises the following compositions in part by weight: 5 to 10 parts of modified polyamide, 5 to 30 parts of flame retardant, 0 to 30 parts of flame retardant synergist and inorganic packing, and 0.5 to 5 parts of dispersing agent, wherein the weight ratio of the flame retardant to the flame retardant synergist is 10-25:100. Flame retardant materials prepared by adding the precipitate-free flame retardant masterbatch into high polymer materials do not have the precipitated flame retardant even if used for a long time, and have good flame retardant effect. Because flame retardant is not precipitated, the surfaces of the flame retardant materials have no 'frosting' phenomenon, and the flame retardant materials prepared from the flame retardant masterbatch are excellent in appearance.

Owner:GUANGDONG HIGH & NEW ENG PLASTICS

Method for resource utilization of dephosphorizing sludge

InactiveCN101781079ANo blooming phenomenonAvoid pollutionConstruction materialSludge treatment by thermal conditioningCompression moldingBrick

The invention relates to a method for resource utilization of solid wastes, in particular to a method for resource utilization of dephosphorizing sludge, which is characterized in that the method comprises the following steps: grinding dephosphorizing sludge which is processed by high phosphorus hematite ore-dressing wastewater to 20 meshes, taking undersize materials to obtain powdery high phosphorus hematite tailings, and standby application; (2) respectively measuring the moisture content of the sieved raw materials, and then taking powdery dephosphorizing sludge and powdery high phosphorus hematite tailings according to the dry weight mass ratio (1-3):2 between the powdery dephosphorizing sludge and the powdery high phosphorus hematite tailings; (2) placing the powdery dephosphorizing sludge and the powdery high phosphorus hematite tailings into a blender for mixing, simultaneously adding water, the addition of water being 10%-12% of the sum of the powdery dephosphorizing sludge and the powdery high phosphorus hematite tailings, and mixing for 4-6 minutes to obtain mixture; (3)compression molding; and (4) baking to form backed bricks. The method is characterized by high waste utilization, simple technological operation, low cost and high product strength.

Owner:WUHAN UNIV OF TECH

Preparation method of modified sulfur coated with two-component film forming agent

The invention relates to a preparation method of modified sulfur coated with a two-component film forming agent. The preparation method is characterized by comprising the following steps: successivelyadding various film forming agents in a stirring tank through a measuring tank for blending and adding an inorganic powder material suspension in the stirring tank for uniform mixing for later use; adding sulfur powder in a mixer in advance and then adding the mixed suspension in an accelerant powder according to the proportion requirements for uniform mixing; mixing the material by adopting themixer, then rolling through a roller, dispersing through a dispersing machine to obtain a mixed material, granulating by using an oscillating granulator, then conveying wet material grains in a dryerfor drying, crushing a dried product through a crusher, cooling, sieving and packaging to obtain a finished product. The preparation method provided by the invention has the advantages that the equipment requirements are simple, the cost is low, the safety is high, the preparation process is quick and efficient, the environment is friendly, no pollution exists, the release rate of sulfur is high at the sulfurization stage, no frost is sprayed, the processing safety performance of a rubber product is improved, and economic benefits are better.

Owner:安徽固瑞特新材料科技有限公司

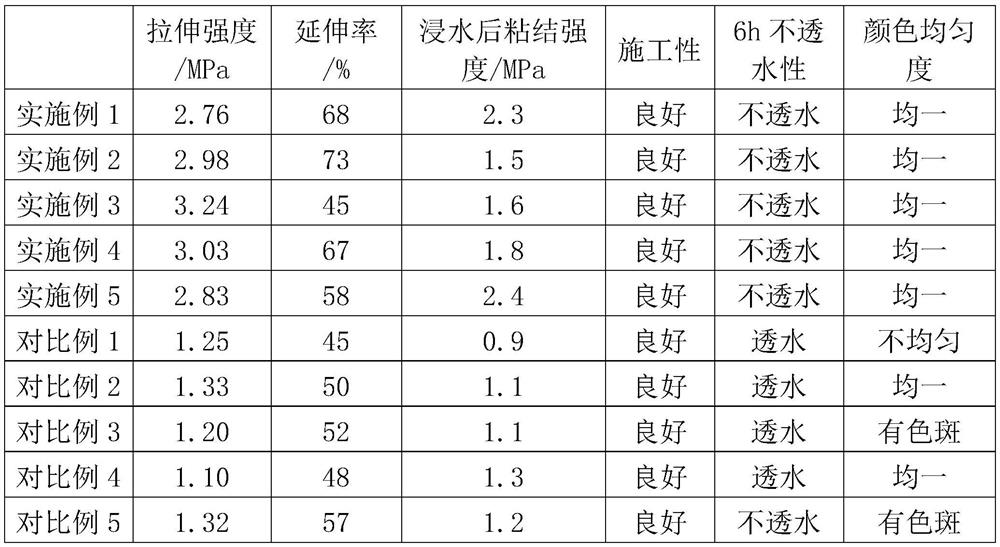

Colored polymer cement waterproof coating and preparation method thereof

The invention discloses a colored polymer cement waterproof coating which comprises a powder material and a liquid material, and the mass ratio of the liquid material to the powder material is (10-15):25; the powder material comprises the following components in parts by weight: 25-55 parts of white cement, 10-20 parts of heavy calcium carbonate and 35-60 parts of modified colored quartz sand, wherein the modified colored quartz sand is prepared by adopting modified pigment powder and EVA emulsion to pretreat quartz sand and then conducting roasting, and the mass ratio of the quartz sand to the modified pigment powder to the EVA emulsion is 1:(0.05-0.1):(0.2-0.4); and the liquid material comprises the following components in parts by weight: 80-100 parts of emulsion, 1-3 parts of a defoaming agent, and 10-15 parts of water, wherein the emulsion is formed by co-doping an EVA emulsion and a styrene-acrylic emulsion in a mass ratio of 1:(1-2.5). The invention also discloses a preparation method of the colored polymer cement waterproof coating. The prepared colored polymer cement waterproof coating is uniform in color, free of color attachment and floating phenomena, high in tensile strength, small in porosity, few in communicating holes and excellent in waterproof effect.

Owner:临海市忠信新型建材有限公司

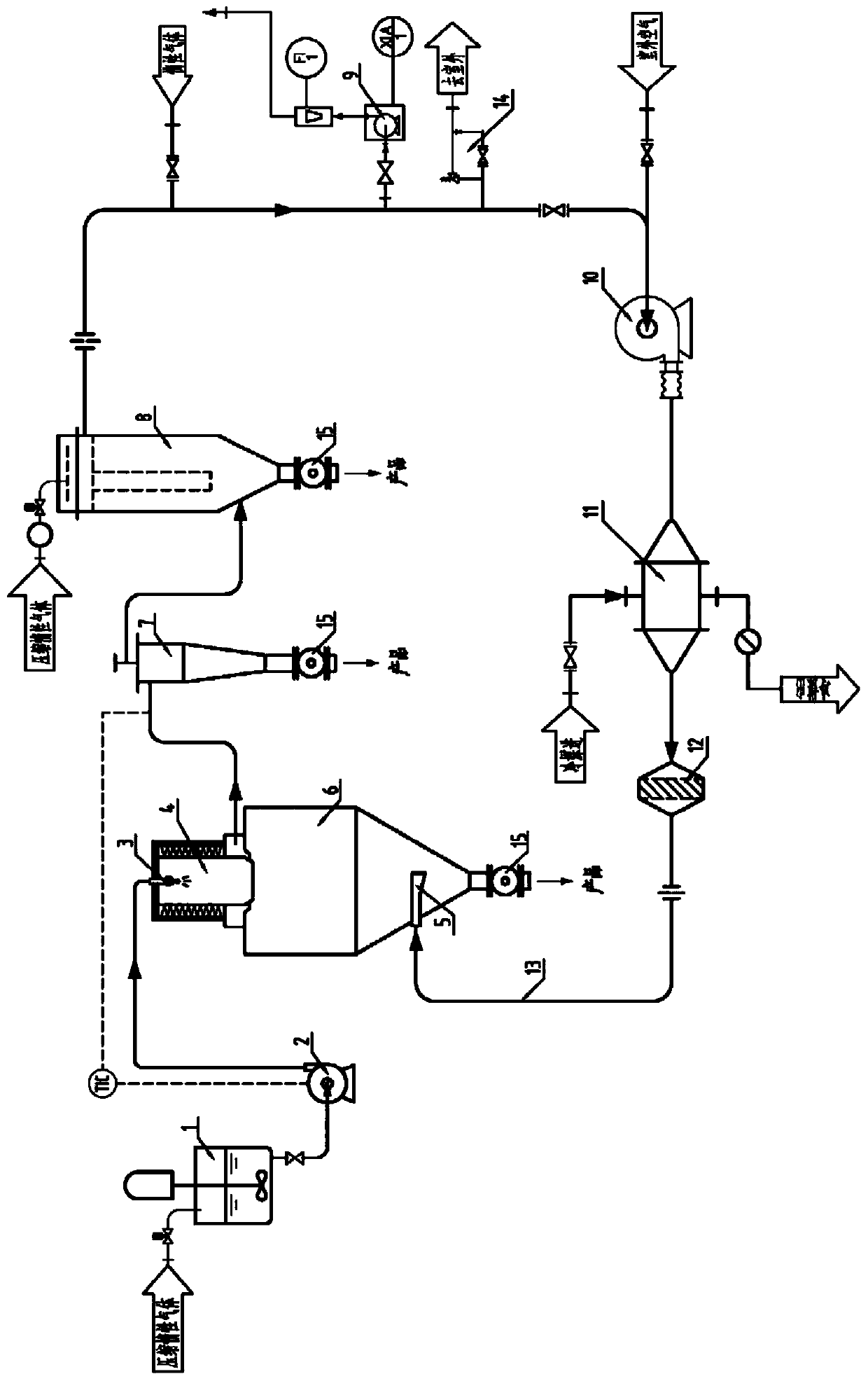

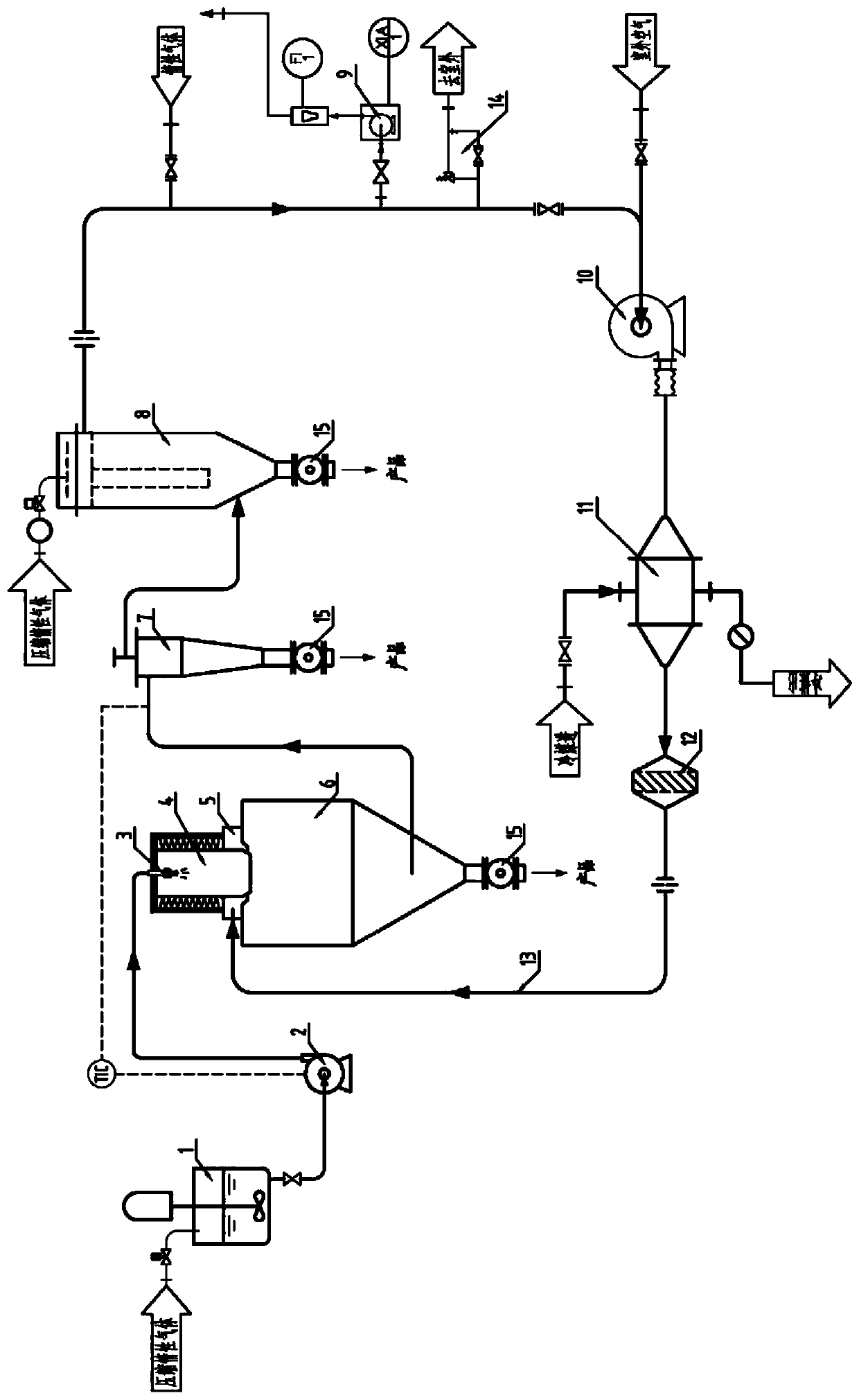

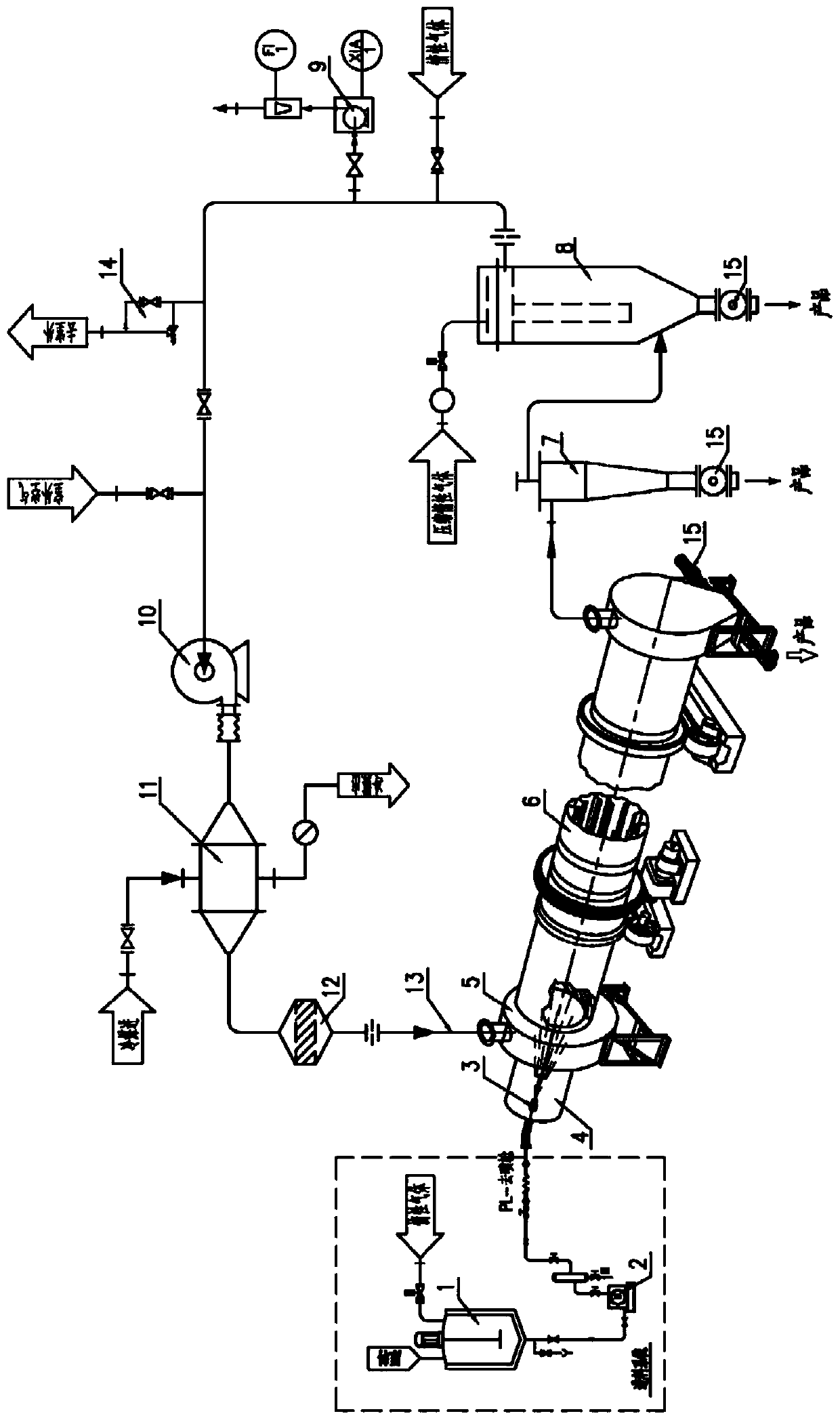

Spray reaction device for closed cycle preparation of insoluble sulfur

PendingCN111039263AImprove stabilitySuitable for large-scale industrializationSulfur preparation/purificationGas analysisPhysical chemistry

The invention discloses a spray reaction device for of insoluble sulfur, and relates to the technical field of preparation equipment of insoluble sulfur for rubber tires and rubber products. The sprayreaction device mainly comprises a melting system, a feeding system, a high-temperature reaction furnace, a cooling chamber, a separation system, a gas analysis system, a cooling system, a pressure balance system and a discharging system. According to the invention, inert gas is adopted to effectively reduce oxidation of sulfur and improve product quality; a quenching section process effectivelyrestrains the reverse reaction, so that the content of insoluble sulfur in a product is directly influenced; insoluble sulfur is obtained by adopting a low-temperature melting reaction method, so thatthe process is environment-friendly; and the spray reaction device can save resources and reduce cost, and has good market prospect.

Owner:江苏艾迪智能装备有限公司

Rubber composite fiber and preparation process thereof

ActiveCN111826743AShorten the timeFacilitates the process of chlorinationFlame-proof filament manufactureFilament/thread formingPolyesterFiber

The invention discloses a rubber composite fiber and a preparation process of the rubber composite fiber. The rubber composite fiber comprises polyester fibers and chlorinated butyl rubber, wherein the polyester fibers are wrapped in the chlorinated butyl rubber, the length of the polyester fibers is 50-100 [mu] m, and the diameter of the polyester fibers is 5-15 [mu] m. The defects in the prior art are overcome, with the process and formula, the strength and elongation of the rubber composite fiber are effectively enhanced, and meanwhile, the aging resistance and flame retardancy of the rubber composite fiber are improved.

Owner:界首市佳美棉业有限公司

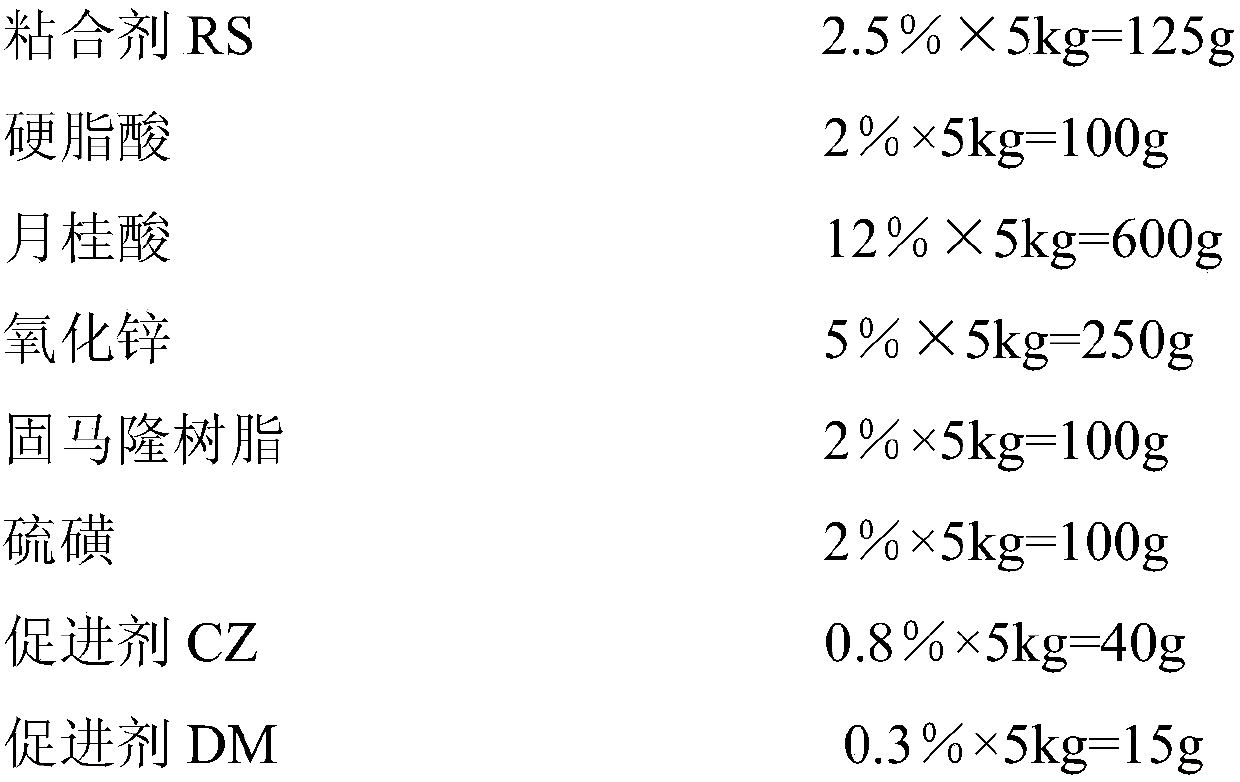

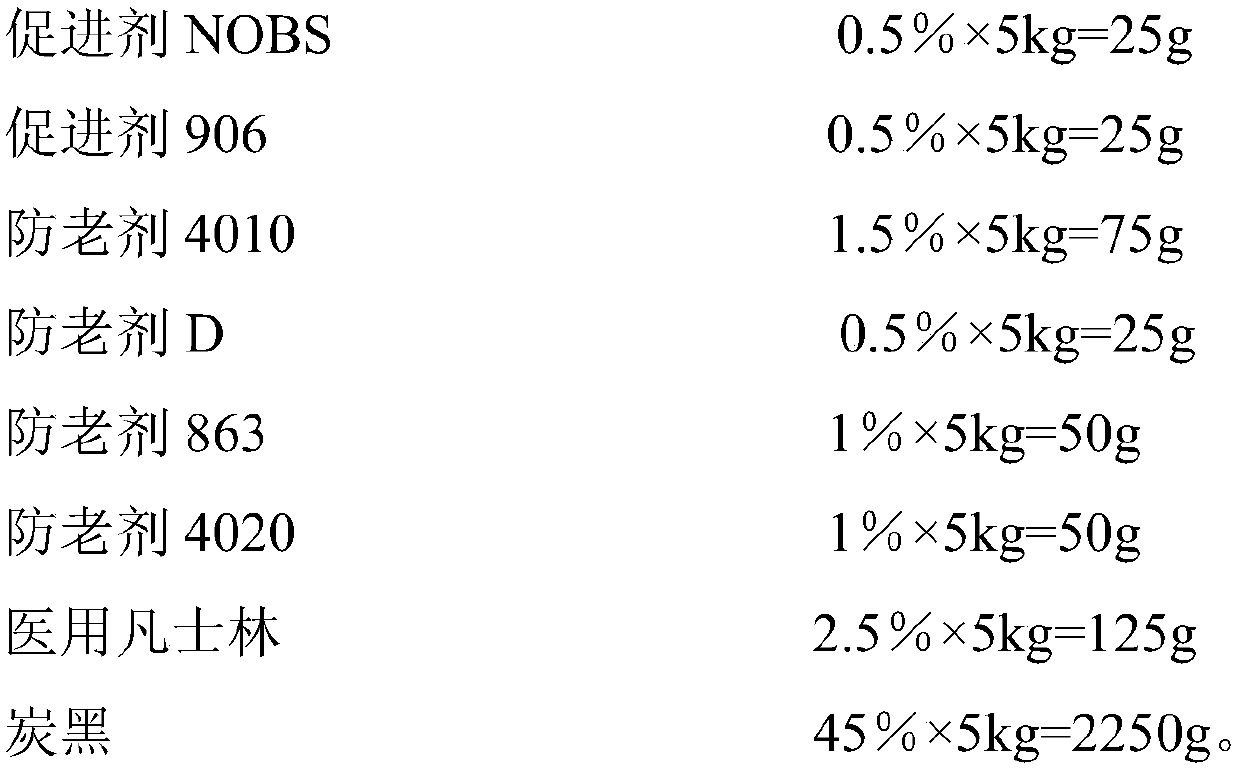

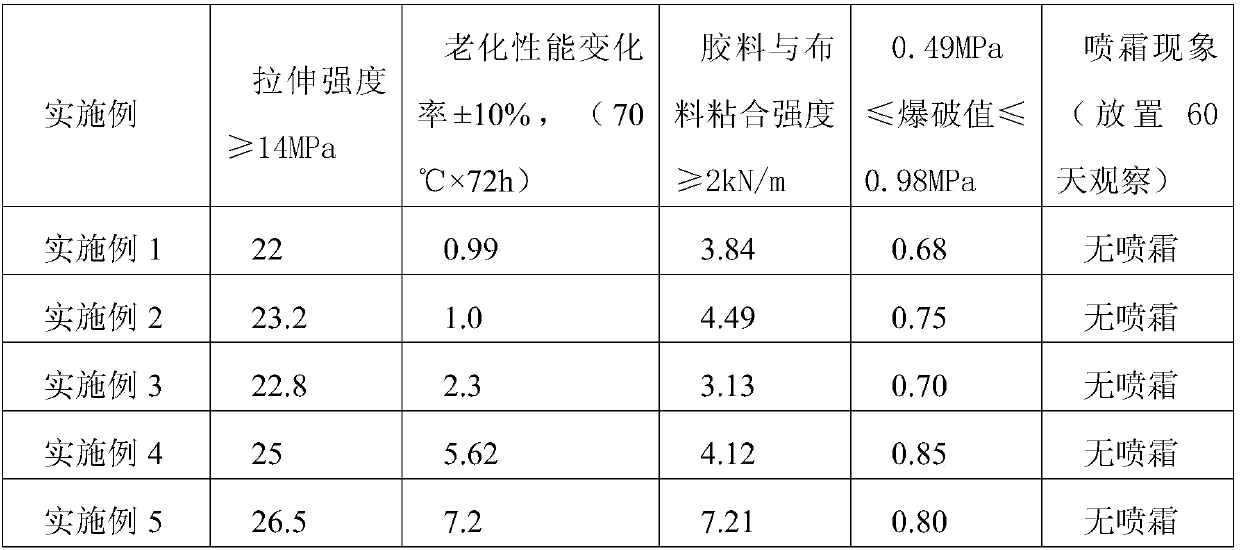

High-strength anti-aging rubber material for flexible plug cap for solid rocket engine nozzle, and preparation method thereof

InactiveCN107652478AImprove adhesionSolve the problem of low tensile strength and frosting on the surface of the productRubber materialAdhesive

The invention discloses a high-strength anti-aging rubber material for a flexible plug cap for a solid rocket engine nozzle, and a preparation method thereof. The rubber material comprises, by weight,100 parts of ribbed smoked sheets, 2-2.5 parts of an adhesive, 4-5 parts of zinc oxide, 2-3 parts of stearic acid, 45-47 parts of carbon black, 12-14 parts of lauric acid, 2-3 parts of coumarone resin, 2-2.5 parts of Vaseline, 1.8-2 parts of sulfur, 1.6-2.1 parts of an accelerator and 3.4-4 parts of an anti-aging agent. The rubber material has the advantages of no blooming, good adhesive propertywith polyamide fabric, high strength and high aging resistance, the tensile strength is up to 25 MPa or above, and the 70 DEG C * 72h aging resistance change rate is 1.04%, the bonding strength of the rubber material and the fabric is 3.84 kN / m or above, the rubber material has a low hardness, and after the rubber material is stored for two years, the surface of the rubber material has no blooming, and the rubber material has a high apparent quality. The preparation method is simple to operate, and is suitable for large-scale production.

Owner:湖北三江航天江北机械工程有限公司

Outdoor PVC transparent film and preparation method thereof

InactiveCN111286134AAddress issues such as insufficient researchGood weather resistancePlasticizerFilm material

The invention belongs to the technical field of transparent film materials, and particularly relates to an outdoor PVC transparent film. The outdoor PVC transparent film is prepared from the followingraw materials in parts by weight: 90-120 parts of PVC resin powder, 10-15 parts of nano powder, 1-3 parts of methyltin, 2-4 parts of plasticizer, 4-7 parts of an impact modifier, 1-3 parts of a gelling agent, 0.3-1 part of an ink absorbent, 1-3 parts of an antistatic agent, 8-15 parts of titanium dioxide and 3-8 parts of a plastic anti-wrinkle agent. The outdoor PVC transparent film and the preparation method have the beneficial effects that the raw materials are easy to obtain; and the film has good antistatic property and stability, can still maintain good mechanical properties in a high-temperature environment for a long time, is not prone to embrittlement and fragility, and is long in service life.

Owner:东阳市李氏塑胶有限公司

Cross-linked phosphorus-containing macromolecular expansion flame-retardant char-forming agent and its preparation method and application

ActiveCN104559204BSolve the problems caused by poor water resistanceImprove solubilityEpoxyPolymer science

Owner:SICHUAN UNIV

A method of coating modified sulfur

ActiveCN106084292BSimple equipment requirementsSuitable for large-scale industrializationVulcanizationEmulsion

Owner:安徽固瑞特新材料科技有限公司

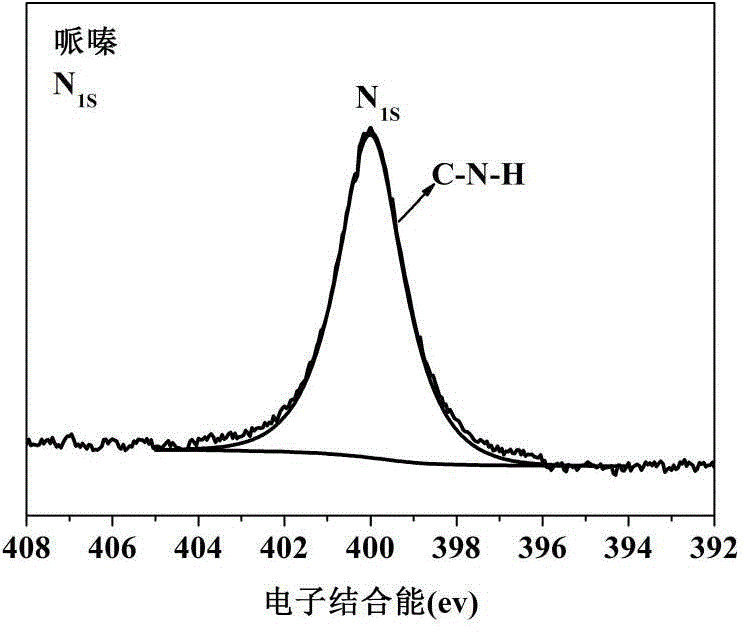

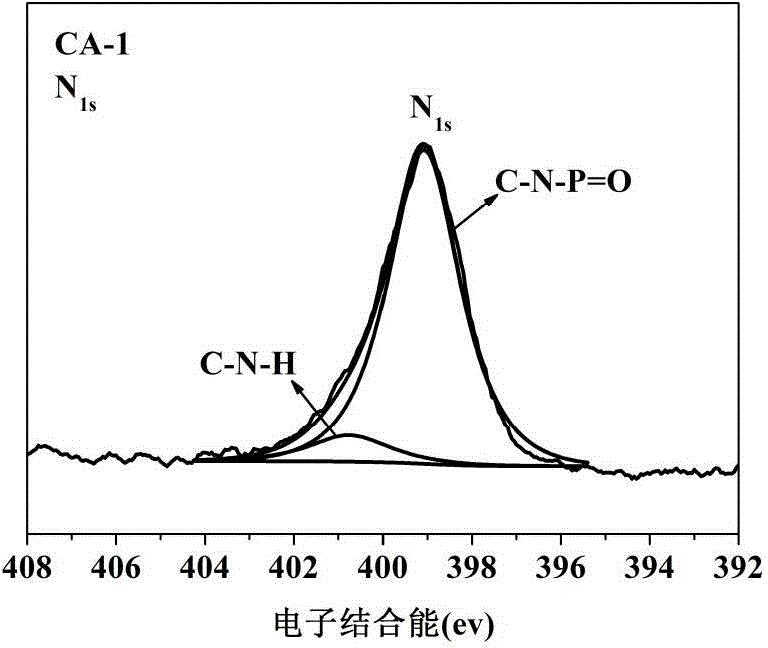

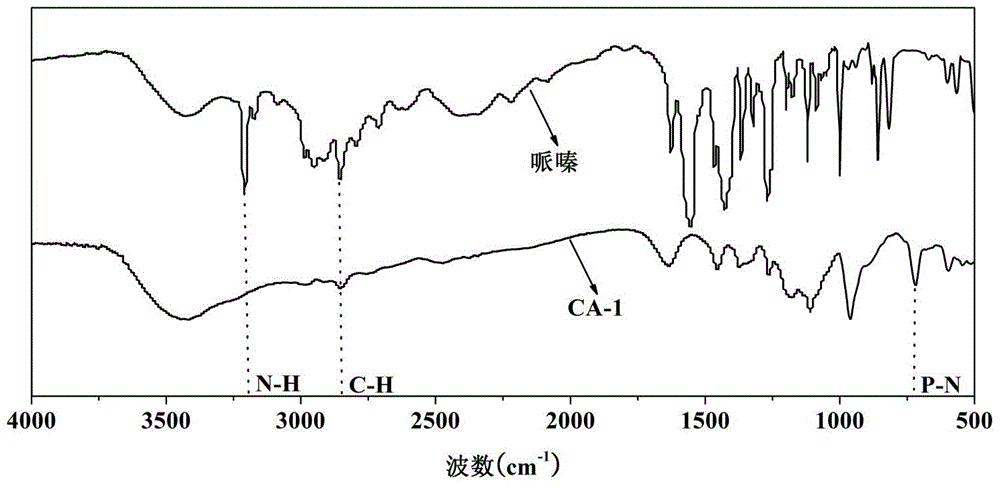

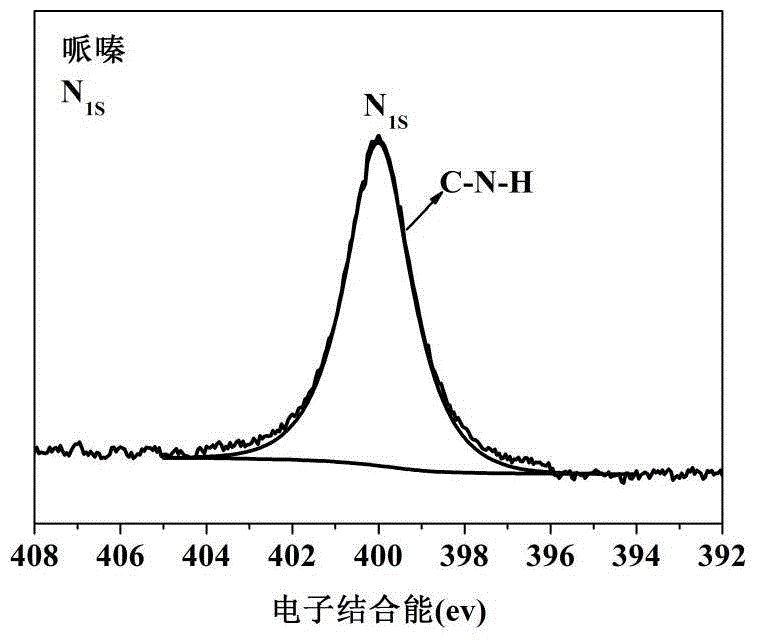

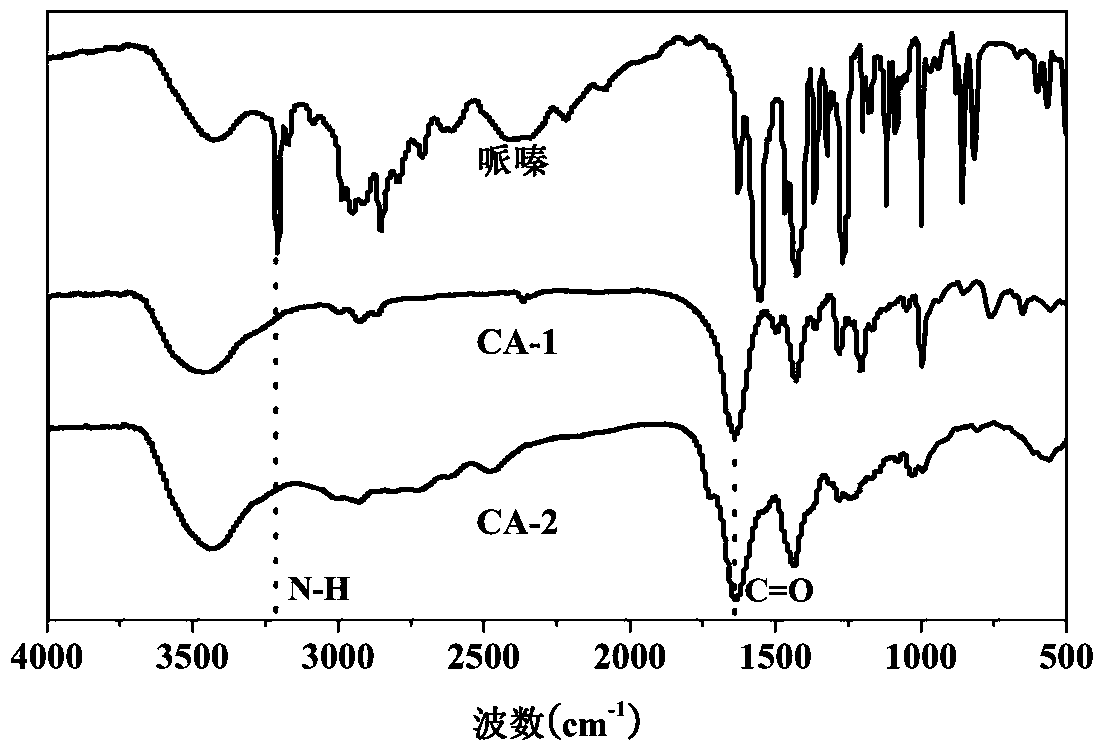

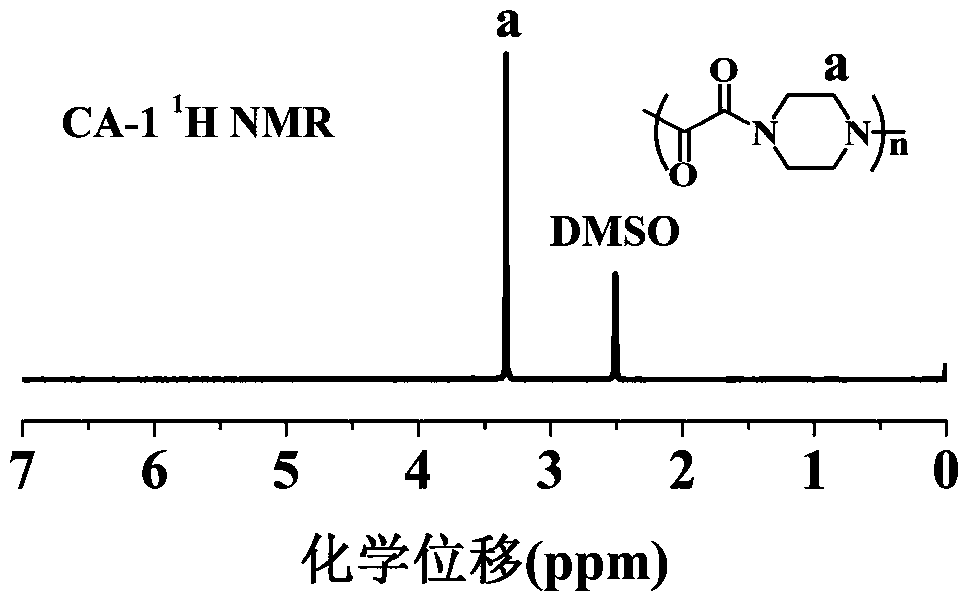

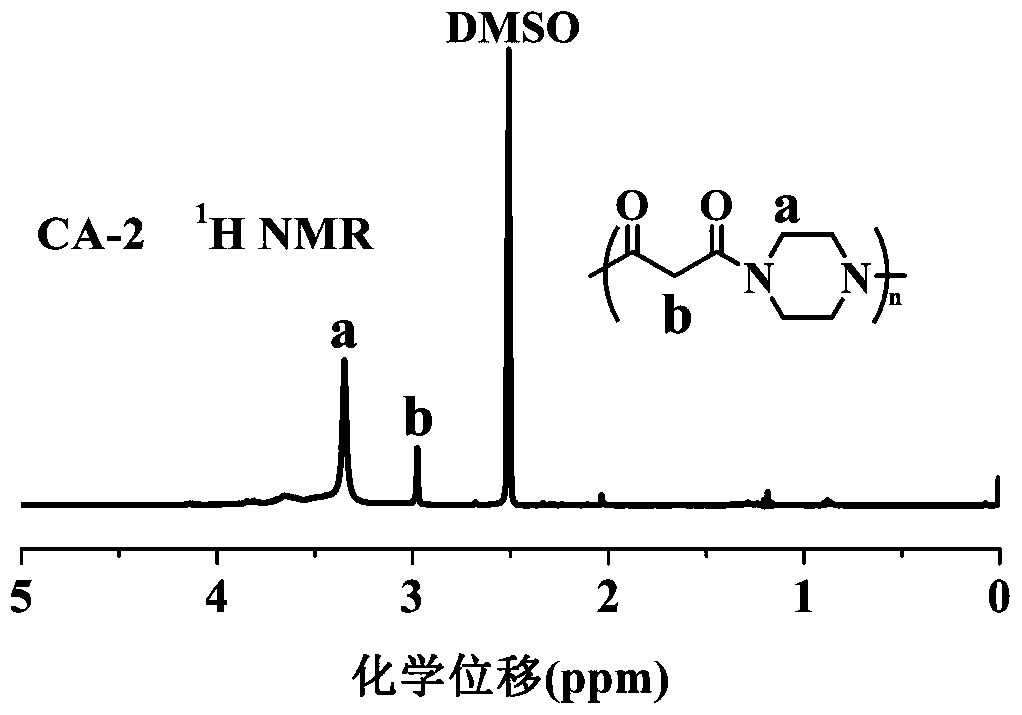

Polyamide-based intumescent flame retardant carbon-forming agent containing piperazine structure in main chain and preparation method and application thereof

ActiveCN105669970BSolve the problems caused by poor water resistanceHigh char formationEpoxyPolymer science

The invention discloses a polyamide intumescent flame-retardant char-forming agent having a main chain containing a piperazine structure; the char-forming agent has the structure general formula defined in the specification, wherein R1 is any one of H, straight-chain or branched-chain alkyl with the number of carbon atoms of 1-4, phenyl, benzyl or phenol, R2 represents straight-chain or branched-chain alkyl with the number of carbon atoms of 1-8, and n is more than or equal to 1. The invention also relates to a preparation method of the intumescent flame-retardant char-forming agent, an application of the intumescent flame-retardant char-forming agent as a carbon source of a novel intumescent flame-retardant system, and an application of the novel intumescent flame-retardant system in halogen-free flame retardancy of polyolefin, polyurethane, polylactic acid, polyamide, ethylene-propylene-diene monomer, silicone rubber and epoxy resin. The prepared intumescent flame-retardant char-forming agent has the advantages of no halogen, low smoke, low toxicity, good thermal stability, high char-forming efficiency, strong water resistance, relatively little influence on mechanical properties of flame-retardant polymers, and simple synthesis process, can be prepared by a one-step method, and is prone to industrialized production.

Owner:SICHUAN UNIV

Factory formula for aging-resistant rubber strip

The invention belongs to the chemical technical filed, relating to production formula of an anti-aging rubber belt, which is composed of neoprene adhesive, natural adhesive, sulfur, vulcanizing agent DTDM, zinc oxide, antioxidant 4010Na, antioxidant ODA, stearic acid, paraffin, high wear-resistance carbon black, accelerator DM, accelerator Na-22 and engine oil. The preparation method is that the materials are face smelted in a face smelting machine. Then certain weight of the face smelted rubber compound is put into a vulcanizer to be vulcanized. The product is obtained after the vulcanization. The product has the advantages of low cost, anti-aging, long service life and no blooming on the surface.

Owner:JIANGSU DAHAI PLASTIC

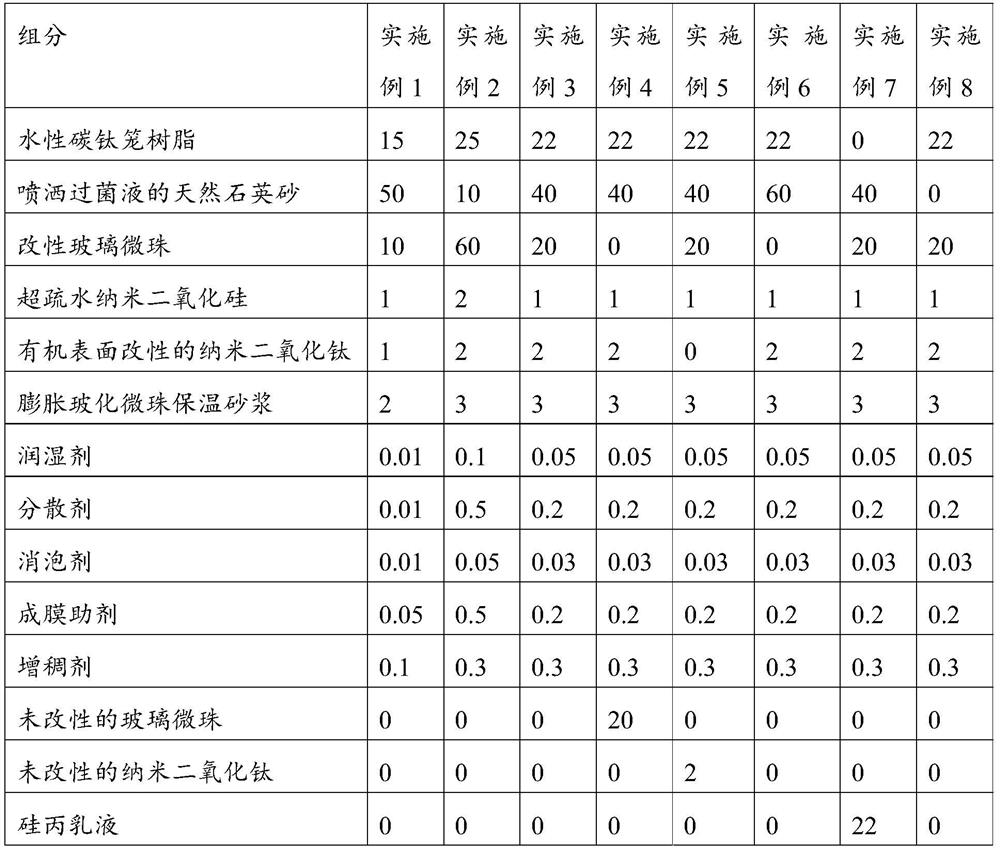

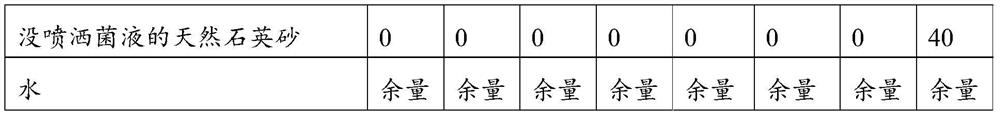

A self-cleaning real stone paint with glass beads as aggregate and preparation method thereof

The invention relates to a self-cleaning real stone paint with glass microspheres as aggregates and a preparation method thereof, comprising: 15-25% of water-based carbon-titanium cage resin; 60-70% of natural quartz sand and modified glass microspheres; superhydrophobic nano Silicon dioxide 1‑2%; organic surface modified nano-titanium dioxide 1‑2%; expanded vitrified bead insulation mortar 2‑3%; wetting agent 0.01‑0.1%; dispersant 0.01‑0.5%; defoamer 0.01‑0.05%; coalescent 0.05‑0.5%; thickener 0.1‑0.3%; water balance. In the present invention, water-based carbon-titanium cage resin, modified glass beads are used for modification, modified nano-titanium dioxide is used for modification, and bacteria liquid containing Bacillus pasteurium is sprayed on the surface of natural quartz sand to cooperate, thereby effectively avoiding the use of hydroxyl Ethyl cellulose, the obtained real stone paint still has good viscosity and rheological properties. The real stone paint of the present invention has excellent stain resistance, excellent water whitening resistance, can overcome the phenomenon of rain marks, and has good color retention and durability, no blooming phenomenon, easy construction, no obstacles in spraying, and small film-forming shrinkage , not falling.

Owner:JINING UNIV

A kind of preparation method of the natural rubber glove that does not spray frost

The present invention relates to a method for preparing natural rubber gloves without blooming, which comprises the steps of: S1, preparing pre-vulcanized natural rubber latex: adding 2-8 parts by weight of a first vulcanizing agent, 0.5-4 parts by weight of a second vulcanizing agent and 0.5-2 parts of vulcanization accelerator is mixed into 90-120 parts of natural rubber latex, pre-vulcanized for 1-10 hours at a temperature of 40 ℃ to 80 ℃, and then parked; the first vulcanizing agent is a resin vulcanizing agent, and the The second vulcanizing agent is thiurams or triazine sodium salts; S2, preparation of impregnated mucilage: by weight, take 90-120 parts of the pre-vulcanized natural latex prepared in step S1, and 0.5-1.5 parts of active agent Mixing, adding a thickener to prepare to a predetermined viscosity; S3, dipping the glove embryo: immersing the glove embryo in the dipping glue prepared in step S2; S4, vulcanizing and drying: preparing the non-blooming natural rubber gloves. The natural rubber gloves prepared by the method of the invention have no blooming phenomenon after being placed indoors for 1 year, and the EN388 test level reaches 3141.

Owner:SHANDONG XINGYU GLOVES

A kind of powder coating for vacuum coating bottom layer of metal substrate and preparation method thereof

InactiveCN103265878BImprove anti-corrosion performanceImprove adhesionAnti-corrosive paintsPolyurea/polyurethane coatingsLow temperature curingPolyester resin

The invention relates to a powder coating for a vacuum coating and a bottom layer of a metal substrate. The powder coating comprises the following components in parts by weight: 60-70 parts of polyester resin, 4-5 parts of curing agent, 0.02-0.04 part of catalyst, 30-40 parts of pigment and filler and 1.5-2.5 parts of additive composition. The powder coating has excellent antiseptic property and super adhesive force with liquid pain, does not give off small molecules, has no influence on the adhesive force of the vacuum coating and the bottom layer and provides a guarantee for firmly attaching the vacuum coating to a liquid paint film; and meanwhile, the powder coating has the advantages of being environment-friendly and energy-saving, realizing the low-temperature curing, having excellent anti-corrosive property, good specular reflection effect, fine and smooth surface, very good decorative effect, excellent day lighting property and excellent quality, being capable of ensuring the high brightness of the vacuum coating and having no phenomena of falling and flooding and can be used for spraying the substrate before the liquid paint is sprayed on the vacuum coating of the metal substrate.

Owner:TIANJIN XIANGSHENG NEW MATERIALS CO LTD

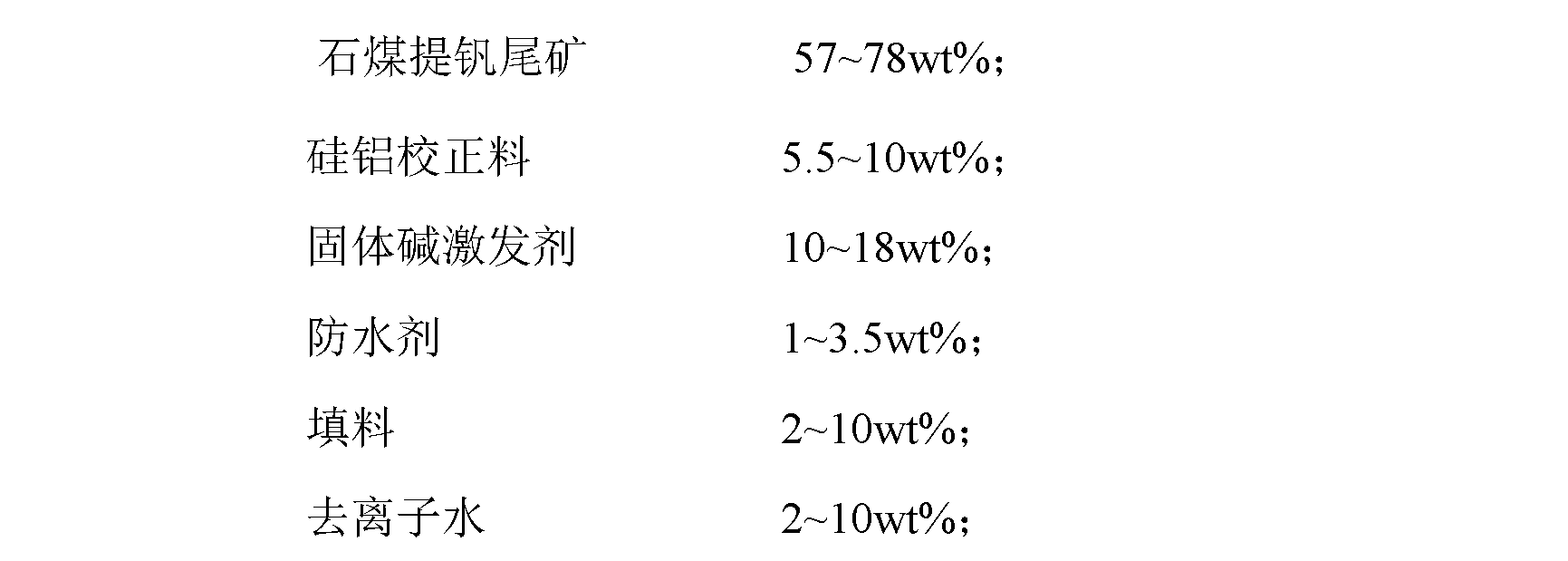

Geopolymer taking stone coal vanadium extracted tailings as major raw materials and preparation method thereof

ActiveCN102180629BSolve pollutionSolve resource problemsSolid waste managementCement productionGeopolymerSolid base

The invention relates to a geopolymer taking stone coal vanadium extracted tailings as major raw materials and a preparation method thereof. According to the technical scheme, the geopolymer is prepared from the following components in percentage by weight: 57-78 percent of stone coal vanadium extracted tailings, 5.5-10 percent of silicon-aluminum corrective addition, 10-18 percent of solid base excitant, 1-3.5 percent of water-proofing agent, 2-10 percent of stuffing and 2-10 percent of deionized water. The preparation method comprises the following steps of: adding a base excitant solution prepared by dissolving the solid base excitant in the deionized water into a mixture prepared from the stone coal vanadium extracted tailings and the silicon-aluminum corrective addition, and stirring; adding the water-proofing agent and stuffing, and stirring; and performing press forming, coating a molded blank with a plastic film, curing, demolding and standing at room temperature. The preparation method has a simple process, low cost and low energy consumption; and the geopolymer has high compression strength, high dry-shrinkage resistance and high impermeability, and is prevented from scumming after standing for a long time.

Owner:WUHAN UNIV OF TECH

Antisepticize and mildew preventive of bamboo wood material

InactiveCN100518517CStrong loss resistanceLow hygroscopicityBiocideAnimal repellantsLoss rateSolubility

The invention provides a kind of antisepsis and antifungal agent for bamboo wood materials, which is mainly obtained by adding zinc-containing compounds, copper-containing compounds and cationic surfactants to the substrate; the present invention uses bamboo vinegar, wood vinegar and grass vinegar as main components, Biological (chemical) wood preservatives are prepared by compounding water-insoluble inorganic compounds, and nitrogen-containing compounds of ammonia, ammonium salts or amines can also be added to increase its solubility. The beneficial effects of the invention are mainly reflected in: strong loss resistance (loss rate less than 2%), low hygroscopicity, no blooming phenomenon, low toxicity, good anti-corrosion and anti-mildew effect, and can also be used for discoloration treatment of wood and bamboo.

Owner:ZHEJIANG FORESTRY UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com