A kind of preparation method of the natural rubber glove that does not spray frost

A technology of natural rubber and natural latex, which is applied in the field of preparation of natural rubber gloves, can solve problems affecting performance, easy to spray out the surface, affect appearance, etc., and achieve the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

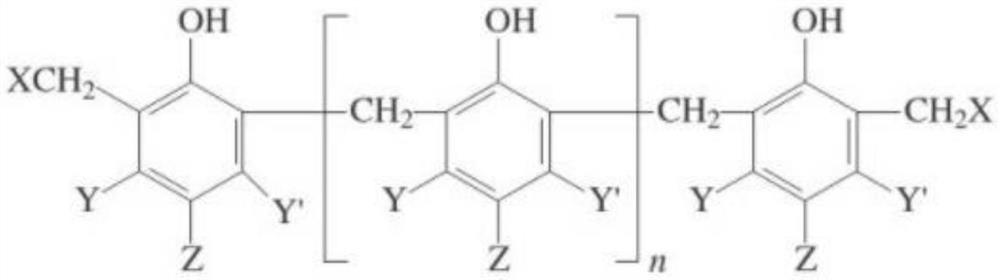

[0038] Step S1, preparation of pre-vulcanized natural rubber latex: 5 parts by weight of the first vulcanizing agent bromomethylol phenolic resin, 1.2 parts of the second vulcanizing agent thiuram TRA (thiuram disulfide), 1 part vulcanization Accelerator zinc diethyldithiocarbamate ZDC, mixed into 100 parts of natural rubber latex (dispersion with a solid content of 60%), pre-vulcanized at a temperature of 65 ° C for 4 hours, and parked for 1 day;

[0039] Step S2, preparation of dipping mortar: by weight, take 100 parts of pre-vulcanized natural rubber latex prepared by step S1, mix with 0.5 part of active agent zinc oxide, and add thickener CMC (2% by mass) to prepare the viscosity 2000mpa.s impregnation mortar;

[0040] Step S3, dipping the glove embryo: soak the chemical fiber knitted glove embryo body at 50°C in 2% calcium nitrate methanol solution coagulant, and perform the dipping coagulant treatment; then immerse the glove embryo into the dipping glue prepared in step ...

Embodiment 2

[0043] Step S1, preparation of pre-vulcanized natural rubber latex: 8 parts by weight of the first vulcanizing agent chlorinated hydroxymethyl phenolic resin, 0.5 parts of the second vulcanizing agent triazine sodium salt (2,4,6-trimercapto-1, 3,5-triazine trisodium salt), 2 parts of vulcanization accelerator DETU and accelerator D (1:1 weight combination), mixed in 120 parts of natural rubber latex (dispersion of solid content 60%), at a temperature of 70 Precure for 2 hours at ℃ and park for 2 days;

[0044] Step S2, preparation of dipping mortar: by weight, take 120 parts of pre-vulcanized natural rubber latex prepared by step S1, mix with 1.5 parts of active agent zinc carbonate, and add thickener CMC (2% by mass) to prepare viscosity 1800mpa.s impregnation mortar;

[0045] Step S3, dipping the glove embryo: soak the chemical fiber knitted glove embryo body at 55°C in 5% calcium nitrate ethanol solution coagulant, and perform the dipping coagulant treatment; then immerse ...

Embodiment 3

[0048] Step S1, preparation of pre-vulcanized natural rubber latex: 2 parts by weight of the first vulcanizing agent brominated hydroxymethyl phenolic resin, 4 parts of the second vulcanizing agent thiurams TRA (thiuram polysulfide), 0.5 parts of vulcanization Accelerator DPG (1,3-diphenylguanidine), mixed into 90 parts of natural rubber latex (dispersion with a solid content of 60%), pre-vulcanized at a temperature of 50 ° C for 5 hours, and parked for 1 day;

[0049] Step S2, preparation of dipping glue: by weight, take 100 parts of prevulcanized natural rubber latex prepared in step S1, mix with 0.5 parts of active agent zinc oxide and zinc stearate (8:2 weight), and add thickening The agent PVA is blended into an impregnated mortar with a viscosity of 1700mpa.s;

[0050] Step S3, dipping the glove embryo: directly immersing the cotton wool glove embryo into the dipping glue prepared in step S2;

[0051] Step S4, vulcanization drying: first pre-vulcanization and drying at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com