Preparation method for non-blooming natural rubber gloves

A technology of natural rubber and natural latex, which is applied in the field of natural rubber glove preparation, can solve the problems affecting the performance, easy-spraying surface, and restrictions, and achieve the effect of improving the quality of rubber products and reducing sulfur precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

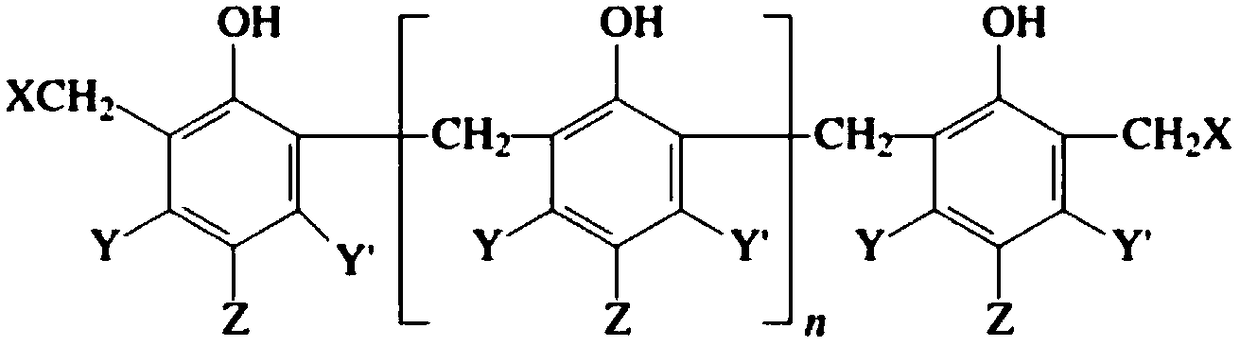

[0038] Step S1, preparation of pre-vulcanized natural rubber latex: 5 parts by weight of the first vulcanizing agent bromomethylol phenolic resin, 1.2 parts of the second vulcanizing agent thiuram TRA (thiuram disulfide), 1 part vulcanization Accelerator zinc diethyldithiocarbamate ZDC, mixed into 100 parts of natural rubber latex (dispersion with a solid content of 60%), pre-vulcanized at a temperature of 65 ° C for 4 hours, and parked for 1 day;

[0039] Step S2, preparation of dipping mortar: by weight, take 100 parts of pre-vulcanized natural rubber latex prepared by step S1, mix with 0.5 part of active agent zinc oxide, and add thickener CMC (2% by mass) to prepare the viscosity 2000mpa.s impregnation mortar;

[0040] Step S3, dipping the glove embryo: soak the chemical fiber knitted glove embryo body at 50°C in 2% calcium nitrate methanol solution coagulant, and perform the dipping coagulant treatment; then immerse the glove embryo into the dipping glue prepared in step ...

Embodiment 2

[0043] Step S1, preparation of pre-vulcanized natural rubber latex: 8 parts by weight of the first vulcanizing agent chlorinated hydroxymethyl phenolic resin, 0.5 parts of the second vulcanizing agent triazine sodium salt (2,4,6-trimercapto-1, 3,5-triazine trisodium salt), 2 parts of vulcanization accelerator DETU and accelerator D (1:1 weight combination), mixed in 120 parts of natural rubber latex (dispersion of solid content 60%), at a temperature of 70 Precure for 2 hours at ℃ and park for 2 days;

[0044] Step S2, preparation of dipping mortar: by weight, take 120 parts of pre-vulcanized natural rubber latex prepared by step S1, mix with 1.5 parts of active agent zinc carbonate, and add thickener CMC (2% by mass) to prepare viscosity 1800mpa.s impregnation mortar;

[0045] Step S3, dipping the glove embryo: soak the chemical fiber knitted glove embryo body at 55°C in 5% calcium nitrate ethanol solution coagulant, and perform the dipping coagulant treatment; then immerse ...

Embodiment 3

[0048] Step S1, preparation of pre-vulcanized natural rubber latex: 2 parts by weight of the first vulcanizing agent brominated hydroxymethyl phenolic resin, 4 parts of the second vulcanizing agent thiurams TRA (thiuram polysulfide), 0.5 parts of vulcanization Accelerator DPG (1,3-diphenylguanidine), mixed into 90 parts of natural rubber latex (dispersion with a solid content of 60%), pre-vulcanized at a temperature of 50 ° C for 5 hours, and parked for 1 day;

[0049] Step S2, preparation of dipping glue: by weight, take 100 parts of prevulcanized natural rubber latex prepared in step S1, mix with 0.5 parts of active agent zinc oxide and zinc stearate (8:2 weight), and add thickening The agent PVA is blended into an impregnated mortar with a viscosity of 1700mpa.s;

[0050] Step S3, dipping the glove embryo: directly immersing the cotton wool glove embryo into the dipping glue prepared in step S2;

[0051] Step S4, vulcanization drying: first pre-vulcanization and drying at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com