Red-mud-fly-ash high-strength heat-preservation building block based on alkali excitation and preparation method thereof

A technology for thermal insulation blocks and fly ash, which can be used in sustainable waste treatment, solid waste management, climate sustainability, etc. Low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

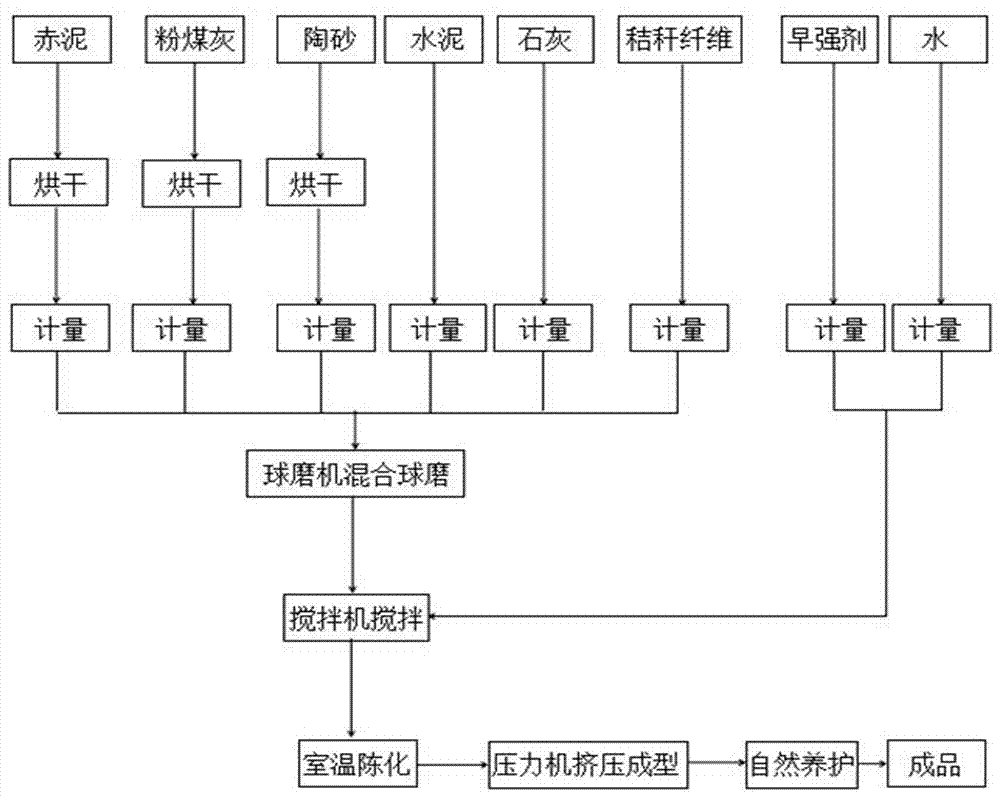

Method used

Image

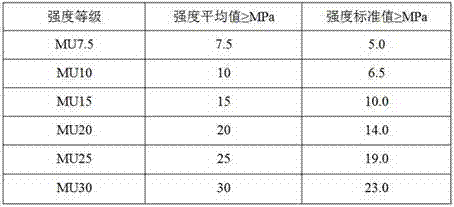

Examples

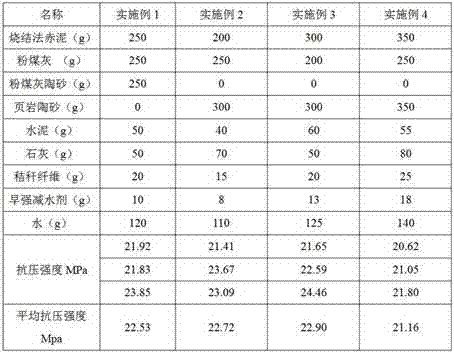

Embodiment 1

[0029] Mix 250g red mud, 250g fly ash, 250g fly ash pottery sand, 50g cement, 50g lime, 20g straw fiber, 10g early strength agent, 120g water (among which red mud, fly ash and ceramsite are dehydrated and dried After ball milling, add water and early strength agent to mix), fully stir, and age at room temperature of 10-15°C for 24 hours, pour the mixture into the mold, shape it under the action of a 40MPa press, and then press The formed blocks are taken out and transported to the conservation site for natural conservation.

Embodiment 2

[0031] Mix 200g red mud, 250g fly ash, 300g shale pottery sand, 40g cement, 70g lime, 15g straw fiber, 8g early strength superplasticizer, 110g water After drying, add water and early strength agent after ball milling), fully stir, and age at room temperature of 10-15°C for 24 hours, pour the mixture into the mold, and shape it under the action of a 40MPa press, and then The pressed blocks are taken out and transported to the conservation site for natural conservation.

Embodiment 3

[0033] Mix 300g red mud, 200g fly ash, 300g shale pottery sand, 60g cement, 50g lime, 20g straw fiber, 13g early strength agent, 125g water After ball milling, add water and early-strength superplasticizer), stir well, age at room temperature of 10-15°C for 24 hours, pour the mixture into the mold, shape it under the action of a 40MPa press, and then put The pressed blocks are taken out and transported to the conservation site for natural conservation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com