High-strength anti-aging rubber material for flexible plug cap for solid rocket engine nozzle, and preparation method thereof

An engine nozzle, solid rocket technology, applied in the field of rubber materials, can solve the problems affecting the anti-aging performance of products, difficult to achieve tensile strength, poor product appearance quality, etc., to avoid blooming phenomenon, high strength and anti-aging. High-quality, high-quality effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

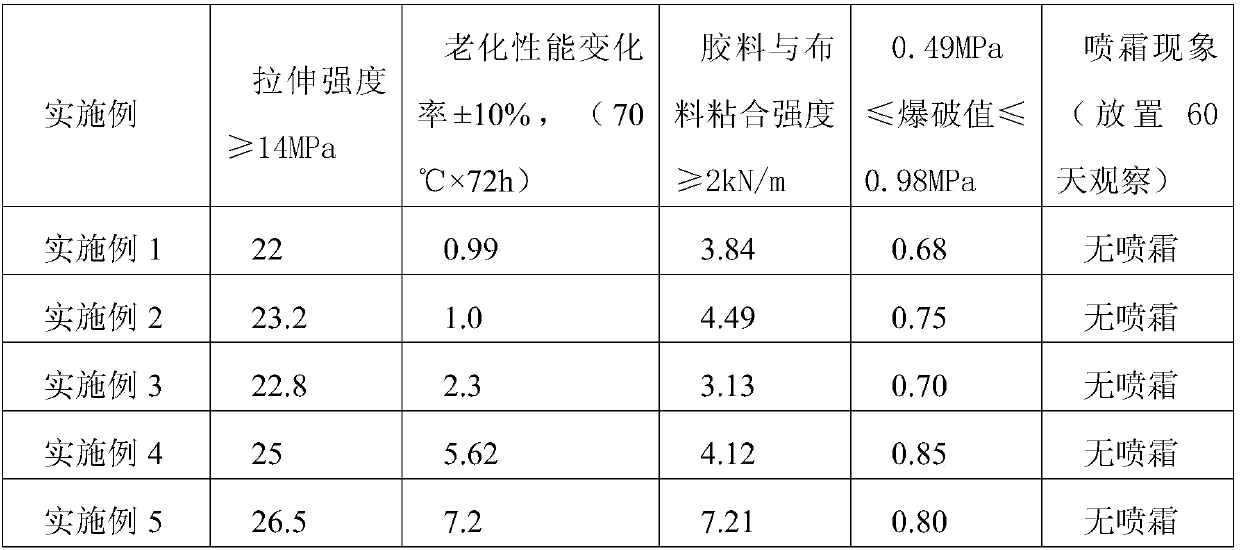

Examples

Embodiment 1

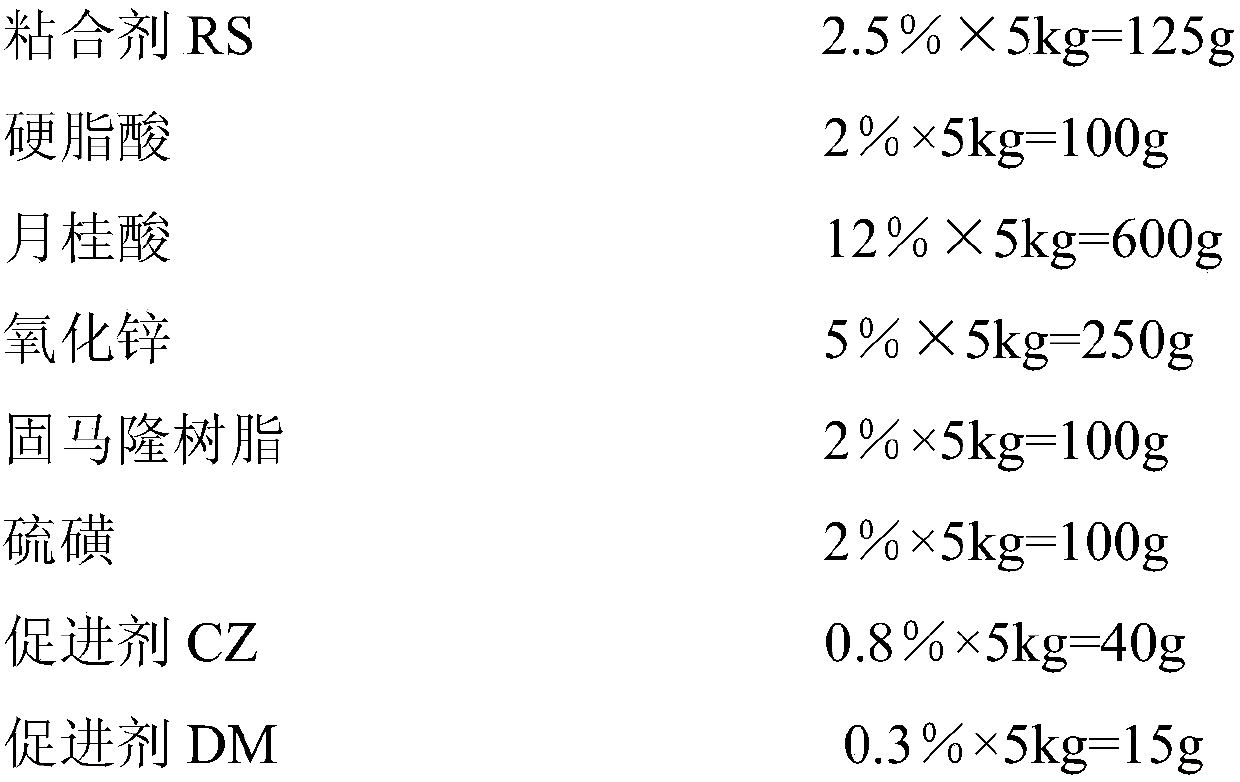

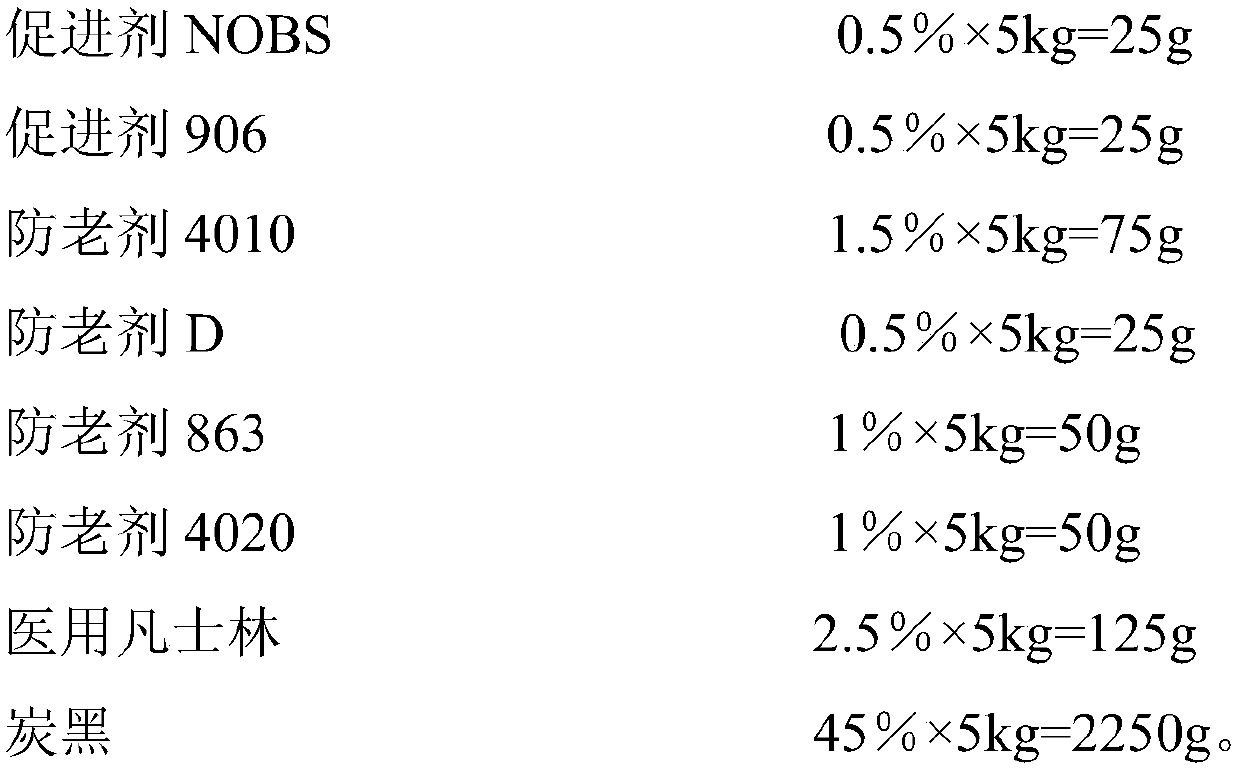

[0035] A high-strength anti-aging rubber material for the flexible plug of a solid rocket motor nozzle. The main raw material contained is first-grade smoked sheet rubber produced in Indonesia. The quality of the first-grade smoked sheet rubber is 5kg. The mass ratio of the compounding agent is as follows:

[0036]

[0037]

[0038] The above-mentioned raw materials are prepared into a high-strength anti-aging rubber material for the flexible plug of the solid rocket motor nozzle according to the following steps:

[0039] 1) Plasticizing the smoked sheet rubber: pass the broken smoked sheet rubber on the open mill for 2 to 3 times with a small roll distance of 1 to 2 mm, then twist the film by 90° and put it back into the roll gap, reciprocating More than 5 times or until the specified time, each section shall not exceed 20 minutes, and the temperature of the roller shall be controlled at 40 ℃ ~ 50 ℃; after plasticizing, it shall be parked for 4 hours before entering the ...

Embodiment 2

[0043] According to the preparation steps of Example 1, a kind of high-strength anti-aging rubber material for the flexible plugging of the solid rocket motor nozzle is prepared. The main raw material smoke sheet rubber quality contained in this material is 5kg, and the proportioning weight of other raw materials is except the following one, Others are the same as in Example 1:

[0044] Accelerator DM 0.2%×5kg=10g.

Embodiment 3

[0046] According to the preparation steps of Example 1, a kind of high-strength anti-aging rubber material for the flexible plugging of the solid rocket motor nozzle is prepared. The main raw material smoke sheet rubber quality contained in this material is 5kg, and the proportioning weight of other raw materials is except the following one, Others are the same as in Example 1:

[0047] Antiaging agent 863 0.8%×5kg=40g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Adhesive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com