A self-cleaning real stone paint with glass beads as aggregate and preparation method thereof

A technology of glass microbeads and self-cleaning, which is applied in the field of architectural coatings. It can solve the problems of whitening of real stone paint coatings when exposed to water, poor water resistance of cellulose, and easy mildew and deterioration. It achieves fast drying speed, small film shrinkage, and good color effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

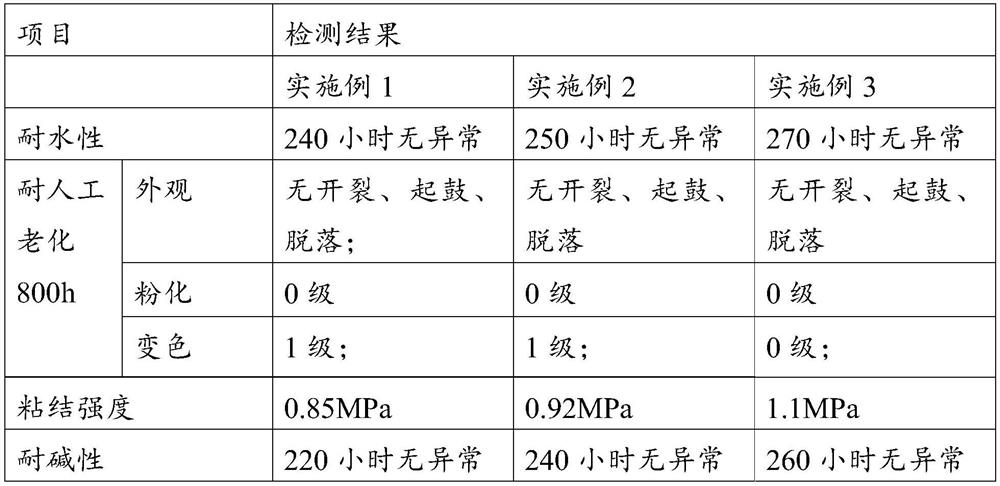

Examples

Embodiment 1- Embodiment 8

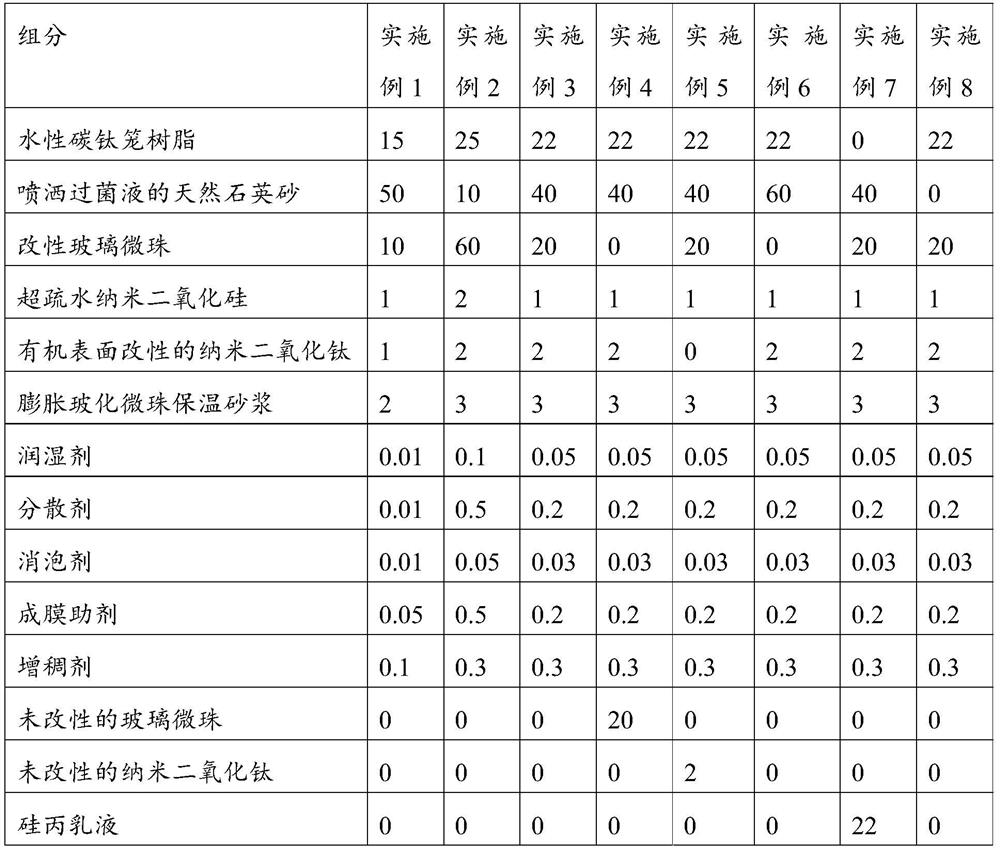

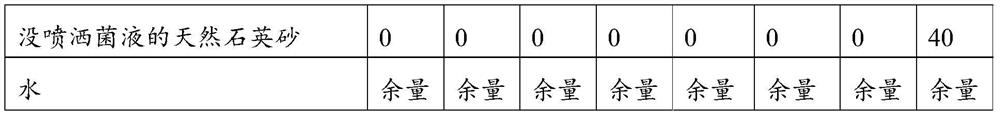

[0037] The glass beads of embodiment 1-8 are aggregate self-cleaning real stone paints, including the components in weight percentage as shown in table 1.

[0038] Table 1 embodiment 1-8 is the component and weight percentage content thereof of aggregate self-cleaning real stone paint with glass microspheres

[0039]

[0040]

[0041] Wherein the particle size of natural quartz sand is 10-120 mesh, and the particle size of superhydrophobic nano silicon dioxide and organic surface modified nano titanium dioxide is 20-200nm. The particle size of water-based carbon-titanium cage resin is 150nm-200nm.

[0042]Modified glass beads are glass beads that are surface-modified by C6 fluorosilane coupling agent and dipropylene glycol. The molar ratio of C6 fluorosilane coupling agent to dipropylene glycol is 2-3:1.

[0043] The organic surface-modified nano-titanium dioxide is carried out surface coating treatment by silane coupling agent, maleic anhydride and oleic acid. The mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com