Powder coating for vacuum coating and bottom layer of metal substrate and preparation method of powder coating

A vacuum coating and powder coating technology, applied in the field of coatings, can solve the problems of poor vacuum coating adhesion, poor lighting, etc., and achieve good adhesion, high brightness, and good mirror reflection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

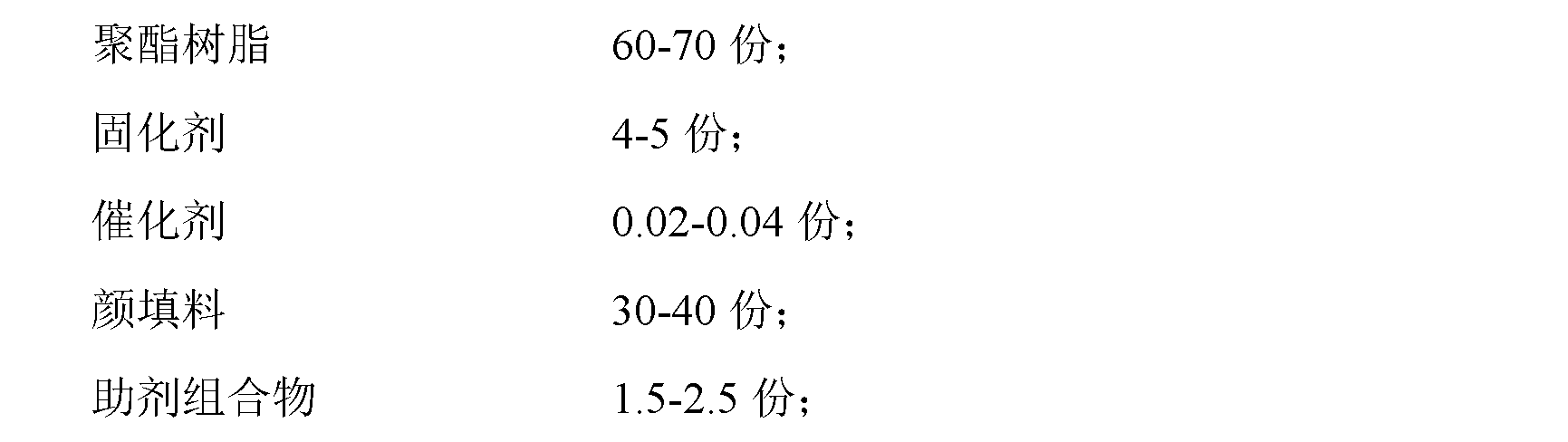

[0043] A kind of powder paint for vacuum coating bottom layer of metal substrate, its raw material composition and its weight are respectively:

[0044]

[0045] The preparation method of the powder coating for the vacuum coating bottom layer of the above-mentioned metal substrate, the steps are as follows:

[0046]Add the above materials to the high-speed mixer, and then add them to the extruder after dry mixing. The temperature in the first zone is 80-90°C, and the extrusion temperature in the second zone is 110-120°C for melting, mixing, extrusion, cooling, Tablets, crushed by a pulverizer, graded, sieved, and packaged to become a powder coating product with a suitable particle size. Finally, it is sprayed on the metal surface and baked at 180°C for 15 minutes to ensure that the coating film is completely cured and no secondary coatings will occur. After curing, the powder coating for the bottom layer of vacuum coating on the metal substrate is obtained.

Embodiment 2

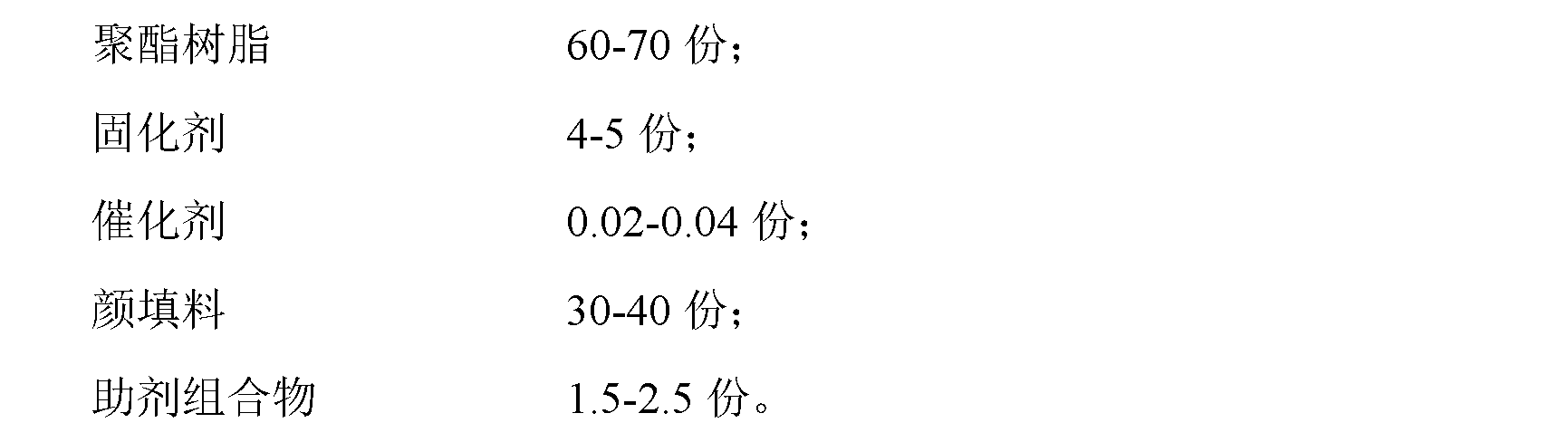

[0048] A kind of powder paint for vacuum coating bottom layer of metal substrate, its raw material composition and its weight are respectively:

[0049]

[0050] The preparation method of the powder coating for the vacuum coating bottom layer of the above-mentioned metal substrate, the steps are the same as in Example 1.

Embodiment 3

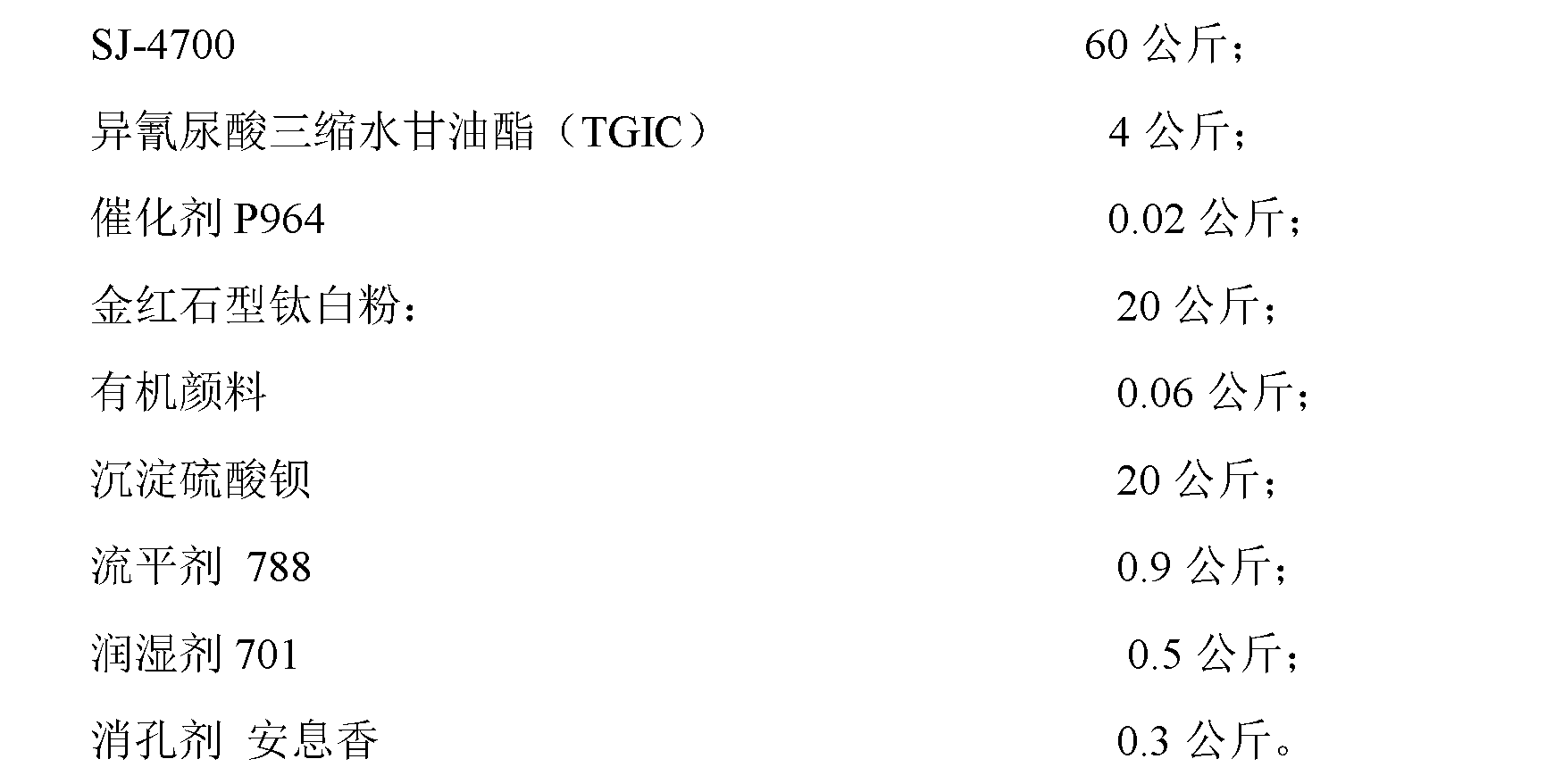

[0052] A kind of powder paint for vacuum coating bottom layer of metal substrate, its raw material composition and its weight are respectively:

[0053]

[0054] The preparation method of the powder coating for the vacuum coating bottom layer of the above-mentioned metal substrate, the steps are the same as in Example 1.

[0055] Practical application effect and test situation of powder coating of the present invention:

[0056] In order to check the practical application effect of the present invention, the specific operation is as follows: spray the powder coating obtained in Example 1 on the metal surface through phosphating treatment, put it into a high-temperature oven and bake it in 180°C / 15-20 minutes to make it After the solidification is complete, take out the sample to cool down, then spray the liquid paint, and then put it in an oven and bake it at 138°C for 45 minutes. The powder coating prepared in Example 2 was finally obtained as a plated sample B according ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com