Application of ionic liquid in polyethylene terephthalate composite fiber

A technology of polyethylene terephthalate and ethylene glycol phthalate, which is applied in the field of PET composite fiber membranes, and can solve the problems of fabric discoloration, long-spotted enzymes, and poor water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Step (1). Dry the PET in vacuum at 100°C for 72 hours;

[0061] Step (2). Add 20g of dried PET and 1g of commercially available organic antibacterial agent to 100g of trifluoroacetic acid in a mass ratio of 100:5, and magnetically stir for 4 hours at room temperature; Solutions of spinning precursors.

[0062] Step (3). First, suck 2 ml of the prepared electrospinning precursor solution into a 5 ml medical syringe syringe, connect the positive electrode of the high-voltage power supply to the spinning stainless steel needle, connect the negative electrode to aluminum foil, and place the aluminum foil at the horizontal position of the stainless steel needle 10 centimeters is used as a collecting plate, and the PET nanofiber film can be collected on the aluminum foil by providing a voltage of 15 kilovolts; the spinning is completed, and the power is turned off.

[0063] The PET nanofiber film prepared in Example 1 is a PET / organic antibacterial composite fiber film.

Embodiment 2

[0065] Step (1). Dry the PET in vacuum at 100°C for 72 hours;

[0066] Step (2). Add 20 g of dried PET and 1 g of silver nitrate solid to 100 g of trifluoroacetic acid in a mass ratio of 100:5, and magnetically stir for 4 hours at room temperature; after obtaining a homogeneous solution, add 2 g of solid lemon Sodium citrate, wherein the mass ratio of silver nitrate and sodium citrate is 1:2, magnetically stirred at room temperature for 4h, the solution of the electrospinning precursor was obtained.

[0067] Step (3). First, suck 2 ml of the prepared electrospinning precursor solution into a 5 ml medical syringe syringe, connect the positive electrode of the high-voltage power supply to the spinning stainless steel needle, connect the negative electrode to aluminum foil, and place the aluminum foil at the horizontal position of the stainless steel needle 10 centimeters is used as a collecting plate, and the PET nanofiber film can be collected on the aluminum foil by providing ...

Embodiment 3

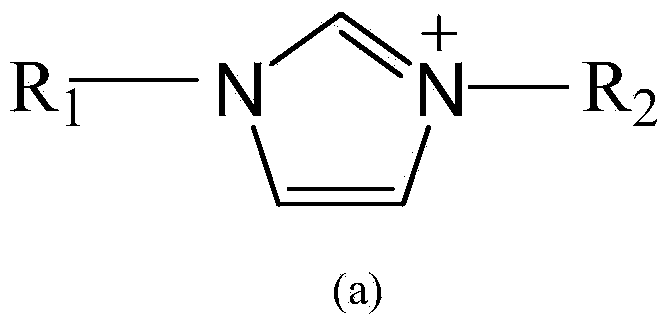

[0070] Step (1). PET and 1-butyl-3-methylimidazolium hexafluorophosphate were vacuum-dried at 100°C for 72 hours;

[0071] Step (2). Add 20 g of dried PET and 1-butyl-3-methylimidazolium hexafluorophosphate to 100 g of trifluoroacetic acid in a mass ratio of 100:0.1, and stir magnetically at room temperature for 4 to 8 hours; After obtaining a uniform solution, a solution of the electrospinning precursor is obtained.

[0072] Step (3). First, suck 2 ml of the prepared electrospinning precursor solution into a 5 ml medical syringe syringe, connect the positive electrode of the high-voltage power supply to the spinning stainless steel needle, connect the negative electrode to aluminum foil, and place the aluminum foil at the horizontal position of the stainless steel needle 10 centimeters is used as a collecting plate, and the PET nanofiber film can be collected on the aluminum foil by providing a voltage of 15 kilovolts; the spinning is completed, and the power is turned off. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com