Automobile hose

A technology for hoses and automobiles, applied in the field of racing hoses, can solve the problems of loose hose sections, low working pressure, hidden quality problems, etc., and achieve the effects of neat and beautiful appearance, high working pressure and soft pipe body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

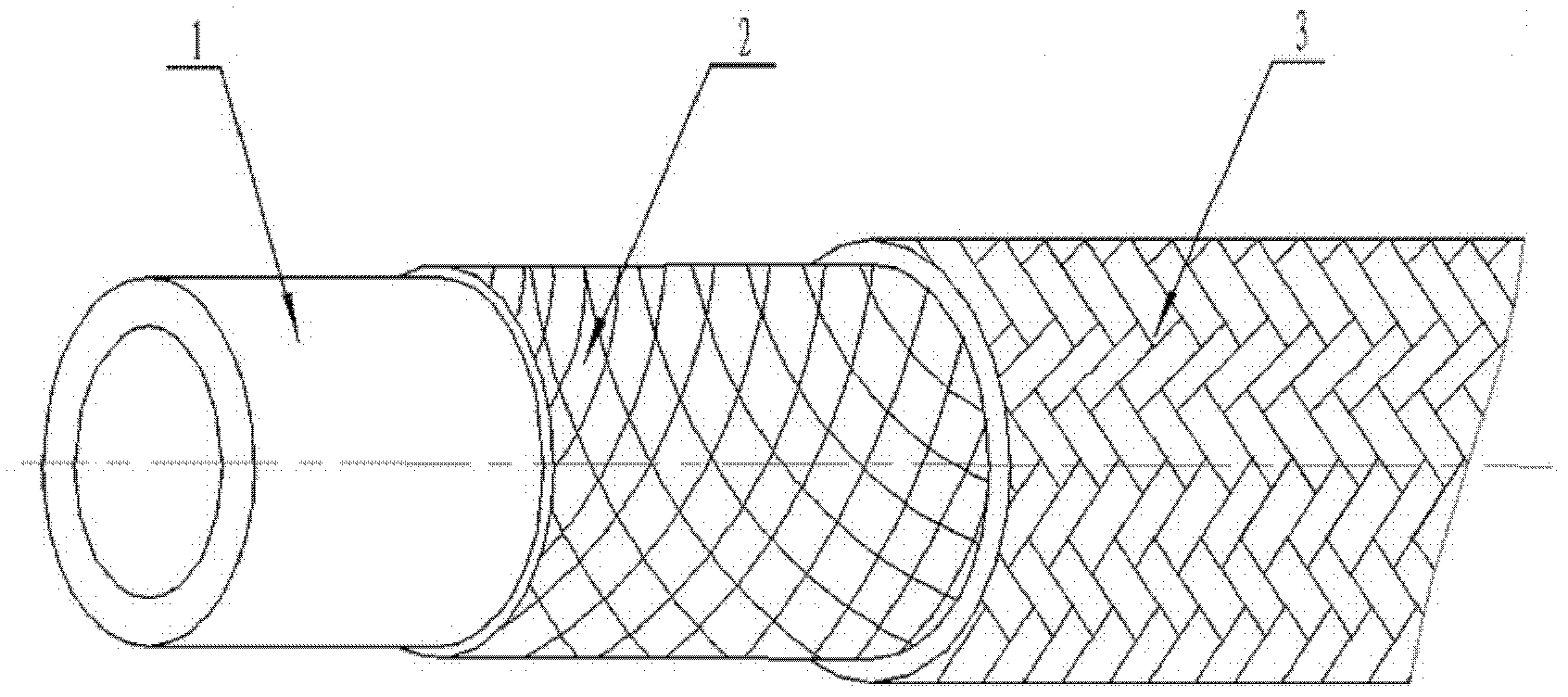

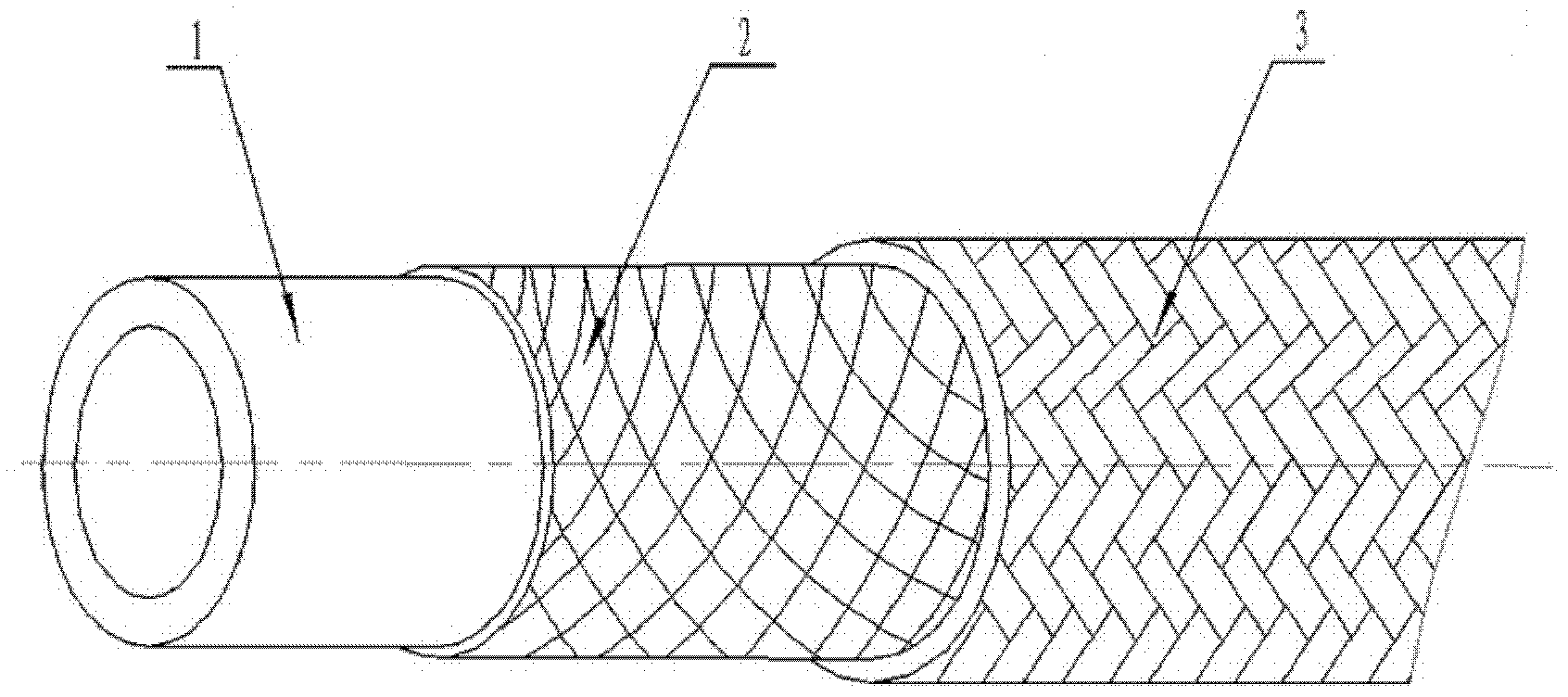

[0022] Refer to attached figure 1 , the present invention includes a rubber inner tube 1, the rubber inner tube 1 is covered with a stainless steel wire braided sheath 2, and the stainless steel wire braided sheath 2 is wrapped with a nylon wire braided sheath 3.

[0023] The rubber inner tube 1 is made of synthetic rubber with excellent comprehensive properties of fuel resistance, lubricating oil resistance and coolant resistance, and is used to transport the corresponding medium; the stainless steel wire braided layer 2 is made of high-strength Φ0.2mm 304 stainless steel wire, stainless steel The silk braided layer 2 is embedded into the outer layer of the rubber inner tube 1 after being vulcanized and shaped, so as to improve the working pressure, vacuum resistance and bending and collapse resistance of the tube body; the nylon thread of the nylon thread braided layer 3 is made of nylon composite Thread, that is, a certain number of nylon long monofilaments with a diameter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com