High-pressure-resisting steam rubber pipe

A high-pressure and steam-resistant technology, applied in the direction of hoses, pipes, pipes/pipe joints/fittings, etc., can solve the problems of increasing the weight of the hose itself, reducing the flexibility of the hose, wasting materials, etc., and achieving environmental protection in the process of preparation and use No pollution, good pressure resistance, soft tube effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A high-pressure steam-resistant rubber hose, comprising the following substances in parts by mass:

[0020] 100 parts of EPDM rubber, 10 parts of chlorosulfonated polyethylene rubber, 0.5 parts of stearic acid, 90 parts of carbon black, 18 parts of antimony oxide, 25 parts of paraffin oil, 2 parts of resin, 3 parts of antioxidant, silane coupling 1 part of agent, 1 part of active agent, 1 part of dispersant, 2 parts of vulcanizing agent, 5 parts of co-crosslinking agent TMPT, and 1 part of accelerator TMTD.

[0021] This kind of high pressure steam resistant hose is made by the following steps:

[0022] Put small pieces of EPDM rubber and chlorosulfonated polyethylene rubber into a sol kettle, control the temperature at 55°C, and add stearic acid, carbon black, antimony oxide, paraffin oil, Resin, anti-aging agent, silane coupling agent, active agent, dispersant, vulcanizing agent, auxiliary cross-linking agent TMPT and accelerator are dissolved, and then stirred and m...

Embodiment 2

[0027] A high-pressure steam-resistant rubber hose, comprising the following substances in parts by mass:

[0028] 100 parts of EPDM rubber, 11 parts of chlorosulfonated polyethylene rubber, 0.6 parts of stearic acid, 94 parts of carbon black, 19 parts of antimony oxide, 27 parts of paraffin oil, 3 parts of resin, 4 parts of antioxidant, silane coupling 1.5 parts of agent, 1.5 parts of active agent, 1.1 parts of dispersant, 2 parts of vulcanizing agent, 5 parts of auxiliary crosslinking agent TMPT, and 1.5 parts of accelerator DPTT.

[0029] The preparation method of this high-pressure steam-resistant rubber hose is the same as in Example 1.

[0030] This kind of high-pressure steam hose has good pressure resistance, soft tube body and good use effect.

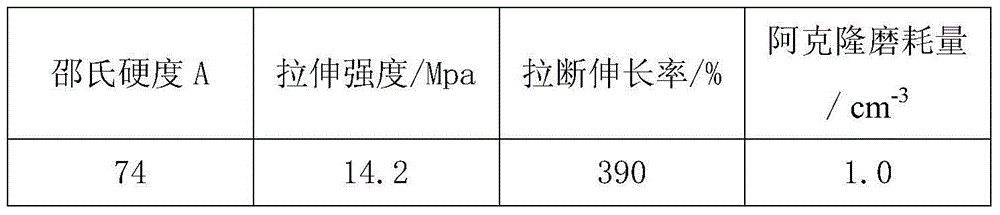

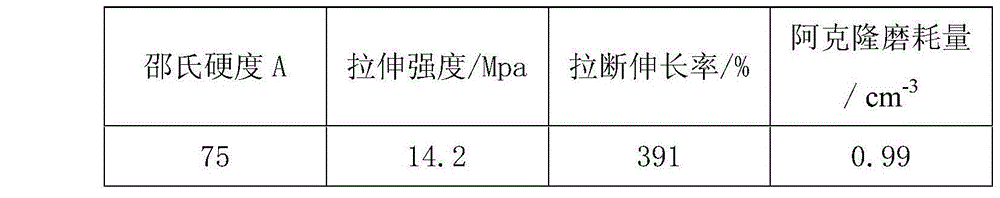

[0031] The performance of this kind of high pressure steam hose is as follows:

[0032] The performance of this kind of high pressure steam hose is as follows:

[0033]

Embodiment 3

[0035] A high-pressure steam-resistant rubber hose, comprising the following substances in parts by mass:

[0036] 100 parts of EPDM rubber, 12 parts of chlorosulfonated polyethylene rubber, 0.8 parts of stearic acid, 99 parts of carbon black, 20 parts of antimony oxide, 30 parts of paraffin oil, 4 parts of resin, 5 parts of antioxidant, silane coupling 2 parts of agent, 2 parts of active agent, 1.2 parts of dispersant, 2 parts of vulcanizing agent, 5 parts of auxiliary crosslinking agent TMPT, 1 part of accelerator M, and 1 part of accelerator DPTT.

[0037] The preparation method of a high-pressure steam hose is the same as in Example 1.

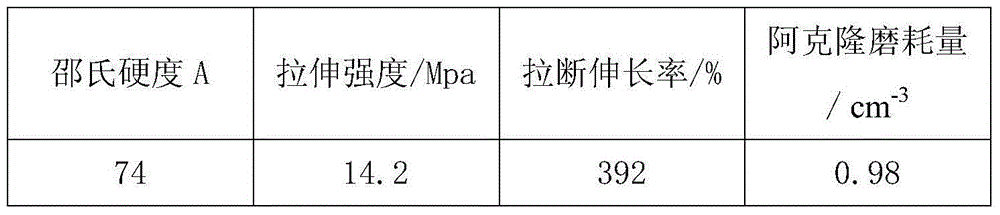

[0038] This kind of high-pressure steam-resistant rubber hose has excellent performance in high-pressure steam resistance.

[0039] The performance of this kind of high pressure steam hose is as follows:

[0040]

[0041] The rubber hose of the present invention has excellent high-pressure steam resistance performance, good pressure b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com