Strong acid tolerant nose pump hose producing method

A production method and hose pump technology, applied in the direction of tubular objects, applications, household appliances, etc., can solve the problems that the inner rubber layer cannot withstand strong acid corrosion, short service life, poor adhesion, etc., and achieve good elastic recovery , excellent wear resistance, soft tube effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

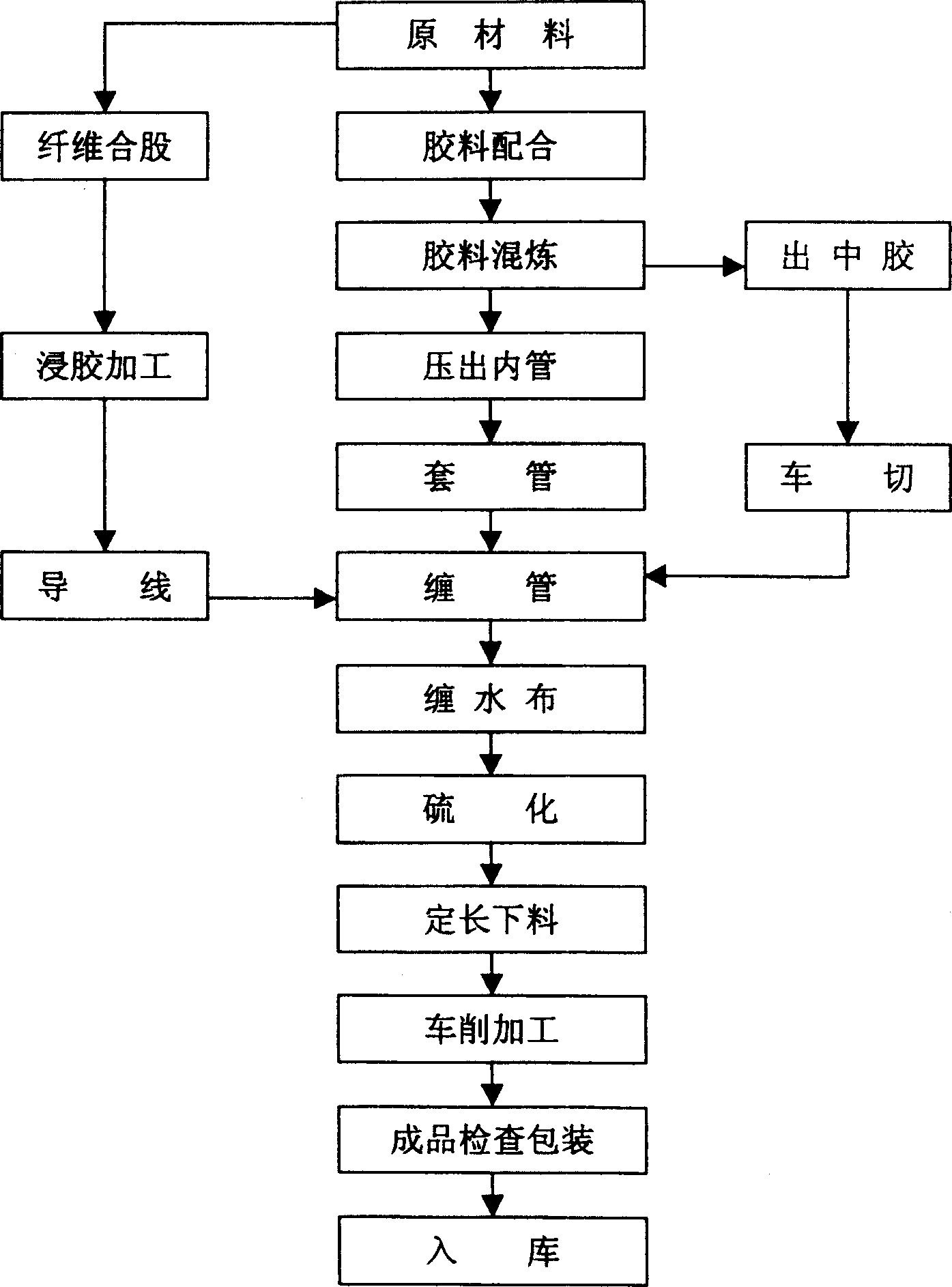

Method used

Image

Examples

Embodiment Construction

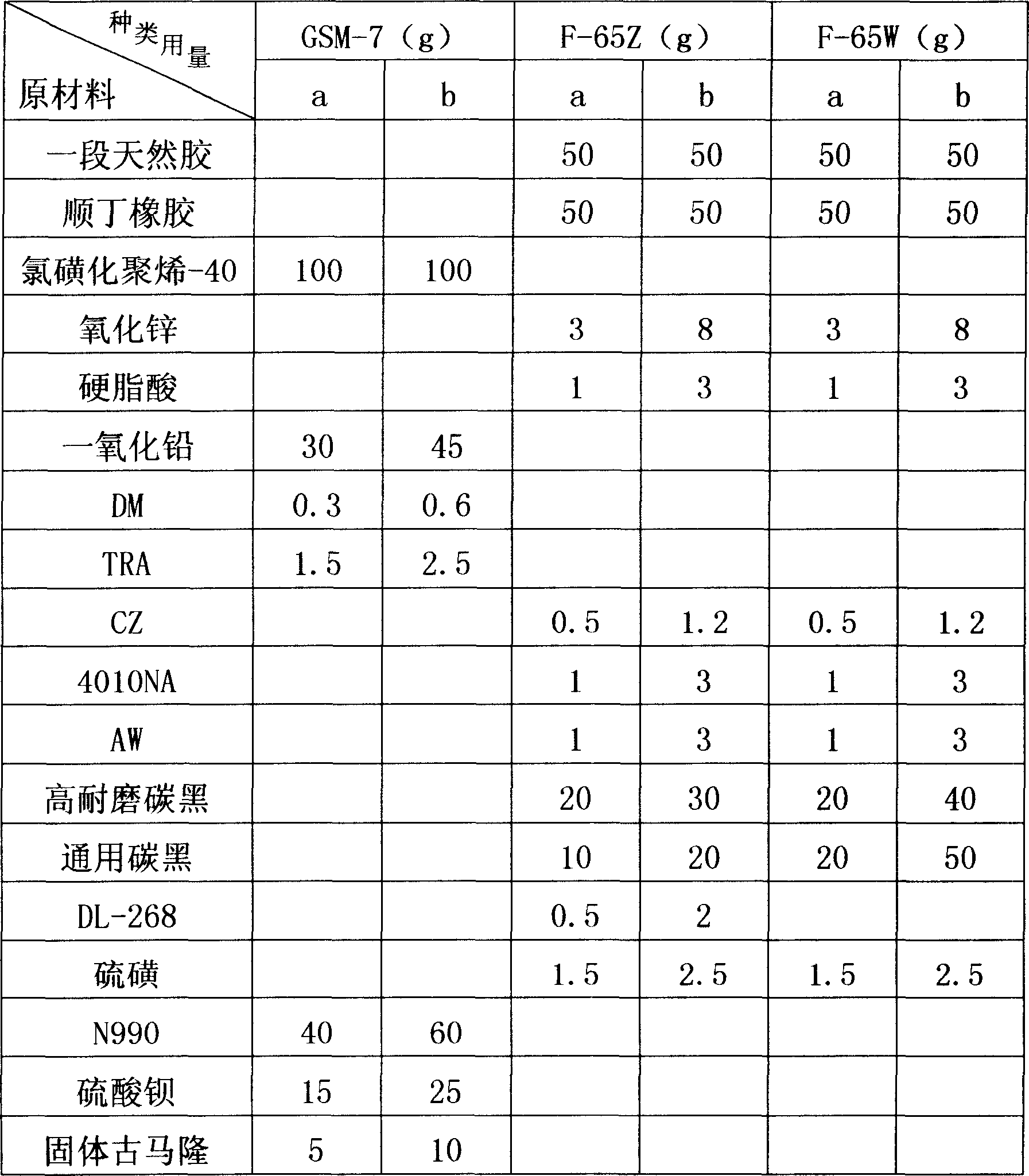

[0013] The formula of the rubber compound is shown in Table 2:

[0014] Table 2

[0015]

[0016] Industrial Vaseline

8

15

DOP

8

15

[0017] Table 2 shows the examples of different rubber ratios of the inner rubber (GSM-7), middle rubber (F-65Z) and outer rubber (F-65W) of the rubber hose, respectively a and b, where g is the weight unit gram.

[0018] Rubber material mixing: each rubber material is pressed with an open mill at 14:00, first press the raw rubber material for 5-7 minutes, and then add zinc oxide, SA, CZ, 4010NA, AW, lead monoxide, DM , TRA, barium sulfate, coumarone, vaseline, DOP, DL-268 pressed for 3-5 minutes, then added carbon black and pressed for 7-8 minutes, finally added sulfur, pressed for 2 minutes, with a roll distance of 0.5-1mm Thin pass 5 times, and finally remove the film.

[0019] Middle film: heat F-65Z rubber with a rubber mixer at 16 o'clock, and release the film in 4-5 mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com