Geopolymer taking stone coal vanadium extracted tailings as major raw materials and preparation method thereof

A technology of geopolymers and main raw materials, applied in the field of geopolymers and its preparation, can solve the problem that the strength of geopolymers cannot be fundamentally improved, the active potential of raw materials has not been fully utilized, and the dry shrinkage resistance and impermeability Reduce the problem of reducing and other problems, and achieve the effect of broadening the source of raw materials, low cost, and good dry shrinkage resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

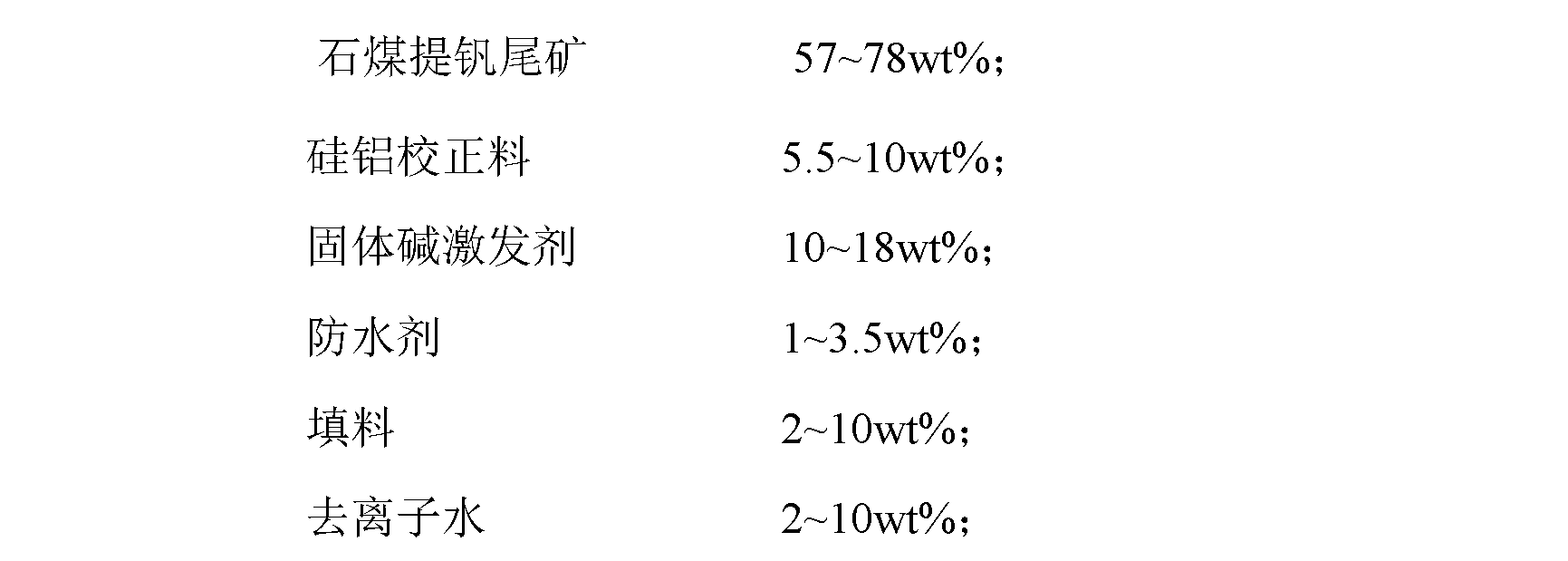

[0030] A geopolymer whose main raw material is vanadium extraction tailings from stone coal and a preparation method thereof. The geopolymer components and their contents are:

[0031] Vanadium extraction tailings from stone coal 57~65wt%;

[0032] Silicon aluminum correction material 5.5 ~ 8wt%;

[0033] Solid base activator 10-15wt%;

[0034] Water repellent 2~3.5wt%;

[0035] Filler 8~10wt%;

[0036] Deionized water 8~10wt%;

[0037] The preparation steps of this geopolymer are:

[0038] Step 1: Add silicon-aluminum correction material to the activated pretreated vanadium extraction tailings from stone coal, stir mechanically for 5-10 minutes, and mix well; in addition, dissolve the solid alkali activator in deionized water to prepare an alkali activator solution;

[0039] Step 2: Add alkali activator solution to the mixture of vanadium extraction tailings from stone coal and silicon-aluminum correction material, and then mechanically stir in a sealed container for 1...

Embodiment 2

[0045] A geopolymer whose main raw material is vanadium extraction tailings from stone coal and a preparation method thereof. The geopolymer components and their contents are:

[0046] Vanadium extraction tailings from stone coal 65-70wt%;

[0047] Silicon aluminum correction material 8 ~ 10wt%;

[0048] Solid base activator 15-18wt%;

[0049] Water repellent 1~2wt%;

[0050] Filler 2~5wt%;

[0051] Deionized water 2~5wt%;

[0052] The preparation steps of this geopolymer are:

[0053] Step 1: Add silicon-aluminum correction material to the activated pretreated stone coal vanadium extraction tailings, stir mechanically for 10-15 minutes, and mix well; in addition, dissolve the solid alkali activator in deionized water to prepare an alkali activator solution;

[0054] Step 2: Add alkali activator solution to the mixture of vanadium extraction tailings from stone coal and silicon-aluminum correction material, and then mechanically stir in a sealed container for 10-20 minu...

Embodiment 3

[0060] A geopolymer whose main raw material is vanadium extraction tailings from stone coal and a preparation method thereof. The geopolymer components and their contents are:

[0061] Vanadium extraction tailings from stone coal 70-78wt%;

[0062] Silicon aluminum correction material 5.5 ~ 8wt%;

[0063] Solid base activator 10-15wt%;

[0064] Water repellent 1~2wt%;

[0065] Filler 2~5wt%;

[0066] Deionized water 2~5wt%;

[0067] The preparation steps of this geopolymer are:

[0068] Step 1: Add silicon-aluminum correction material to the activated pretreated vanadium extraction tailings from stone coal, stir mechanically for 5-10 minutes, and mix well; in addition, dissolve the solid alkali activator in deionized water to prepare an alkali activator solution;

[0069] Step 2: Add alkali activator solution to the mixture of vanadium extraction tailings from stone coal and silicon-aluminum correction material, and then mechanically stir in a sealed container for 20-30...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com