A method of coating modified sulfur

A sulfur and modification technology, applied in the field of coating modified sulfur, can solve the problems of low purity of insoluble sulfur products, unstable insoluble sulfur, easy conversion into ordinary sulfur, etc., and achieves low modification cost, improved melting point and thermal stability. The effect of simple and easy-to-obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

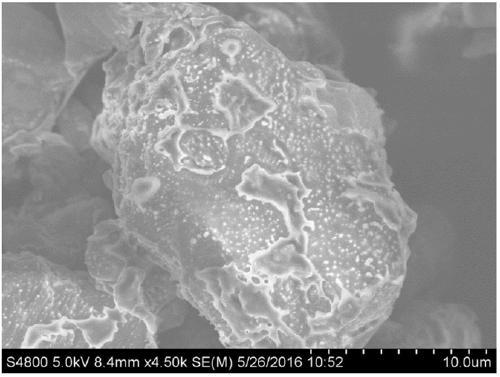

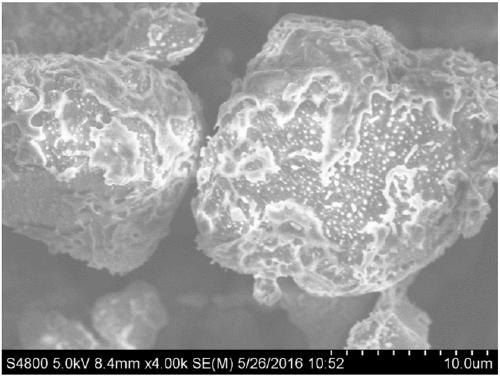

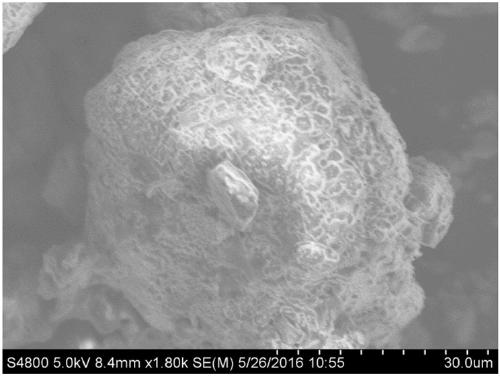

Image

Examples

Embodiment 1

[0040] Weigh 20g of silicon dioxide, 20g of talcum powder and mix with 360g of water to prepare a suspension with a concentration of 10% by mass, add 0.04g of silicon-oxygen coupling agent KH550 to treat and grind to a uniformly dispersed suspension with a particle size of 100 μm or less. Add 20g of water-based polyurethane A539 to the treated suspension and stir for 5 minutes, then add 100g of sulfur, stir for 5 minutes to obtain a mixture of coated modified sulfur, dry and dehydrate in an oven at 80°C, crush and sieve to obtain Coated modified sulfur. Take 7.5g of coated sulfur for experiment, 120 ℃ internal mixer mixing, formula 1502 styrene-butadiene rubber 100, zinc oxide 5, accelerator CZ0.6, N234 carbon black 30, the physical properties of rubber were tested according to national standards.

Embodiment 2

[0042] Weigh 10g of alumina, 10g of pottery clay and 20g of water to prepare a suspension with a concentration of 50% by mass, add 0.2g of polyvinyl alcohol to treat and grind to a uniformly dispersed suspension with a particle size below 10μm, and 1g of methyl acrylate Add to the treated suspension and stir for 120min, then add 100g of sulfur, stir for 120min to obtain a mixture of coated modified sulfur, dry and dehydrate in an oven at 88°C, crush and sieve to obtain coated modified sulfur below 200μm . Take 7.5g of coated sulfur for experiment, 120 ℃ internal mixer mixing, formula 1502 styrene-butadiene rubber 100, zinc oxide 5, accelerator CZ0.6, N234 carbon black 30, the physical properties of rubber were tested according to national standards.

Embodiment 3

[0044] Weigh 1g of aluminum silicate and mix with 9g of water to prepare a suspension with a concentration of 10% by mass, add 0.05g of polyethylene glycol to treat and grind to a uniformly dispersed suspension with a particle size below 1 μm, and mix 15g of acrylic resin anionic emulsion Add 3M-68 to the treated suspension and stir for 60 minutes, then add 100g of sulfur, and stir for 30 minutes to obtain a mixture of coated modified sulfur, dry and dehydrate in an oven at 100°C, crush, and sieve to obtain a coating of less than 100 μm Modified sulfur. Take 7.5g of coated sulfur for experiment, 120 ℃ internal mixer mixing, formula 1502 styrene-butadiene rubber 100, zinc oxide 5, accelerator CZ0.6, N234 carbon black 30, the physical properties of rubber were tested according to national standards.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com