Flame-retardant high polymer material based on compounding of phosphorus containing char-forming agents and hypophosphite/phosphonate

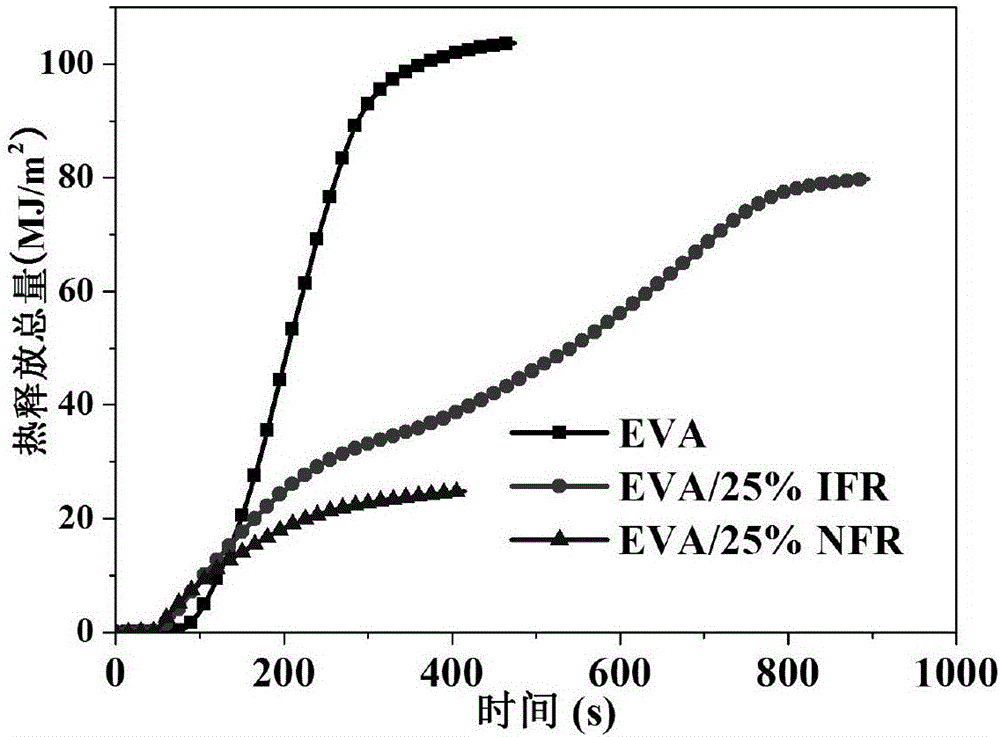

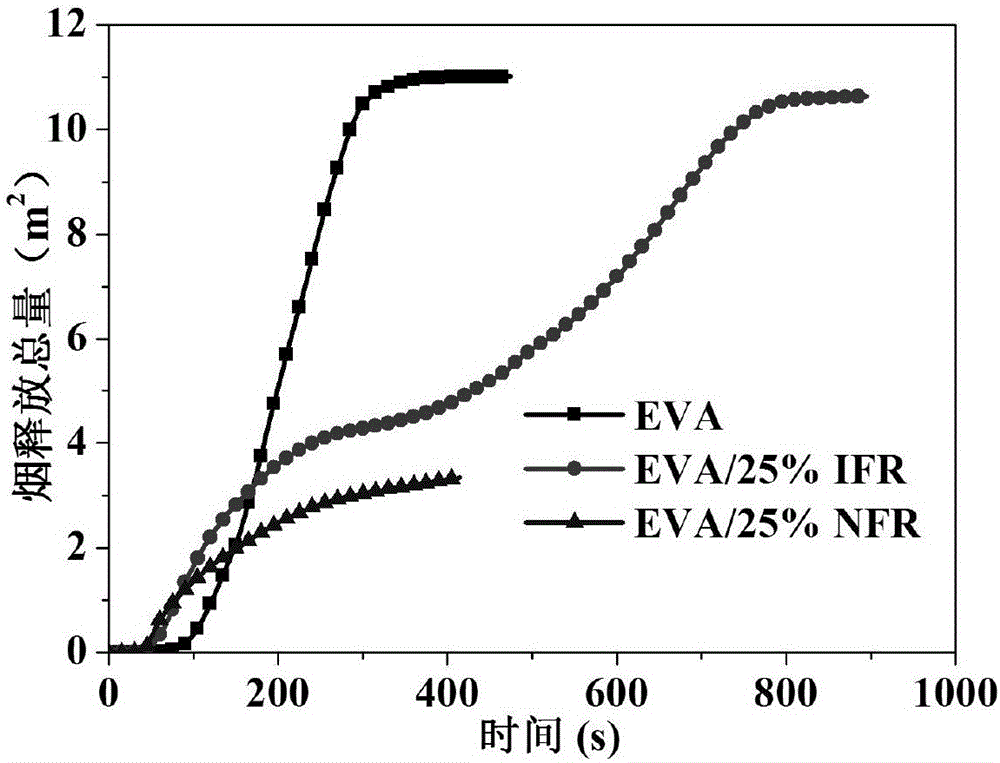

A polymer material and phosphonate technology, applied in the field of halogen-free flame-retardant polymer materials, can solve the problems of unsustainable flame retardancy, unsatisfactory smoke suppression effect, and reduced total release, so as to achieve low smoke generation, Good smoke suppression effect, the effect of adding less

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

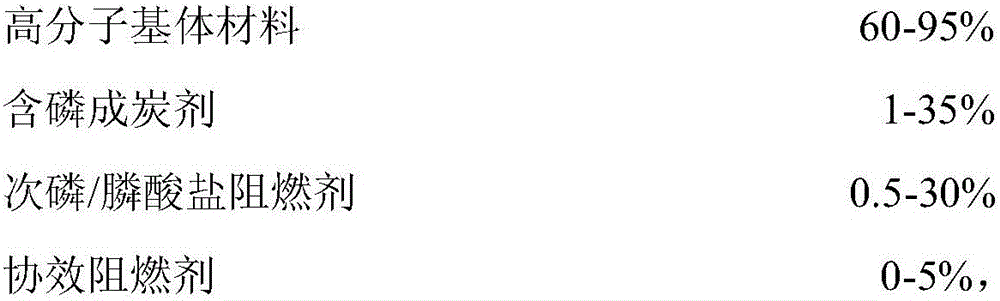

Method used

Image

Examples

Embodiment 1

[0033] 60% low-density polyethylene (PE), 30% phosphorus-containing char-forming agent (obtained from the reaction of ethylenediamine), 5% aluminum diisobutylphosphinate flame retardant and 5% by mass percentage % The synergistic flame retardant zinc borate is dried in a vacuum oven for 8 hours, mixed evenly, then placed in a twin-screw extruder at a temperature of 150-180°C to melt and extrude, cooled, granulated and dried.

[0034] The oxygen index of the obtained halogen-free flame-retardant PE material is 38.0%, and the UL-94 vertical combustion rating is V-0. Compared with the pure substrate in the cone calorimetry test, the total amount of heat release is reduced by 70.5%, and the total amount of smoke release is reduced by 67.5%. %, after soaking in hot water at 70°C for 168h and drying, the vertical burning test grade remains unchanged, and the oxygen index only decreases by 0.1%.

Embodiment 2

[0036] In terms of mass percentage, 69% polypropylene (PP), 1% phosphorus-containing char-forming agent (obtained from the reaction of ethanolamine), 25% phenylisobutylphosphinate aluminum flame retardant and 5% di Calcium isobutylphosphinate flame retardant is dried in a vacuum oven for 8 hours, mixed evenly, then placed in a twin-screw extruder at a temperature of 190-220°C to melt and extrude, cooled, granulated and dried.

[0037] The oxygen index of the obtained halogen-free flame-retardant PP material is 39.0%, and the UL-94 vertical combustion rating is V-0. Compared with the pure substrate in the cone calorimetry test, the total amount of heat release is reduced by 65.5%, and the total amount of smoke release is reduced by 62.8% %, after soaking in hot water at 70°C for 168 hours and drying, the vertical burning test grade remains unchanged, and the oxygen index only decreases by 0.4%.

Embodiment 3

[0039] 70% polystyrene (PS), 28.5% phosphorus-containing char-forming agent (derived from the reaction of phenylenediamine), 0.5% aluminum hypophosphite flame retardant and 1% synergistic flame retardant by mass percentage The powdered stone is dried in a vacuum oven for 8 hours, mixed evenly, then placed in a twin-screw extruder at a temperature of 210-240°C to melt and extrude, cooled, granulated and dried.

[0040] The oxygen index of the obtained halogen-free flame-retardant PS material is 35.0%, and the UL-94 vertical combustion rating is V-0. Compared with the pure substrate in the cone calorimetry test, the total amount of heat release is reduced by 60.2%, and the total amount of smoke release is reduced by 56.6%. %, after soaking in hot water at 70°C for 168h and drying, the vertical burning test grade remains unchanged, and the oxygen index drops by 0%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com