Spray reaction device for closed cycle preparation of insoluble sulfur

A closed-loop, spray reaction technology, applied in the preparation/purification of sulfur, can solve the problems of poor quenching effect, low conversion rate, and no reaction device mentioned, and achieves reduction of scorch, improvement of self-adhesion, and good economic benefits. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

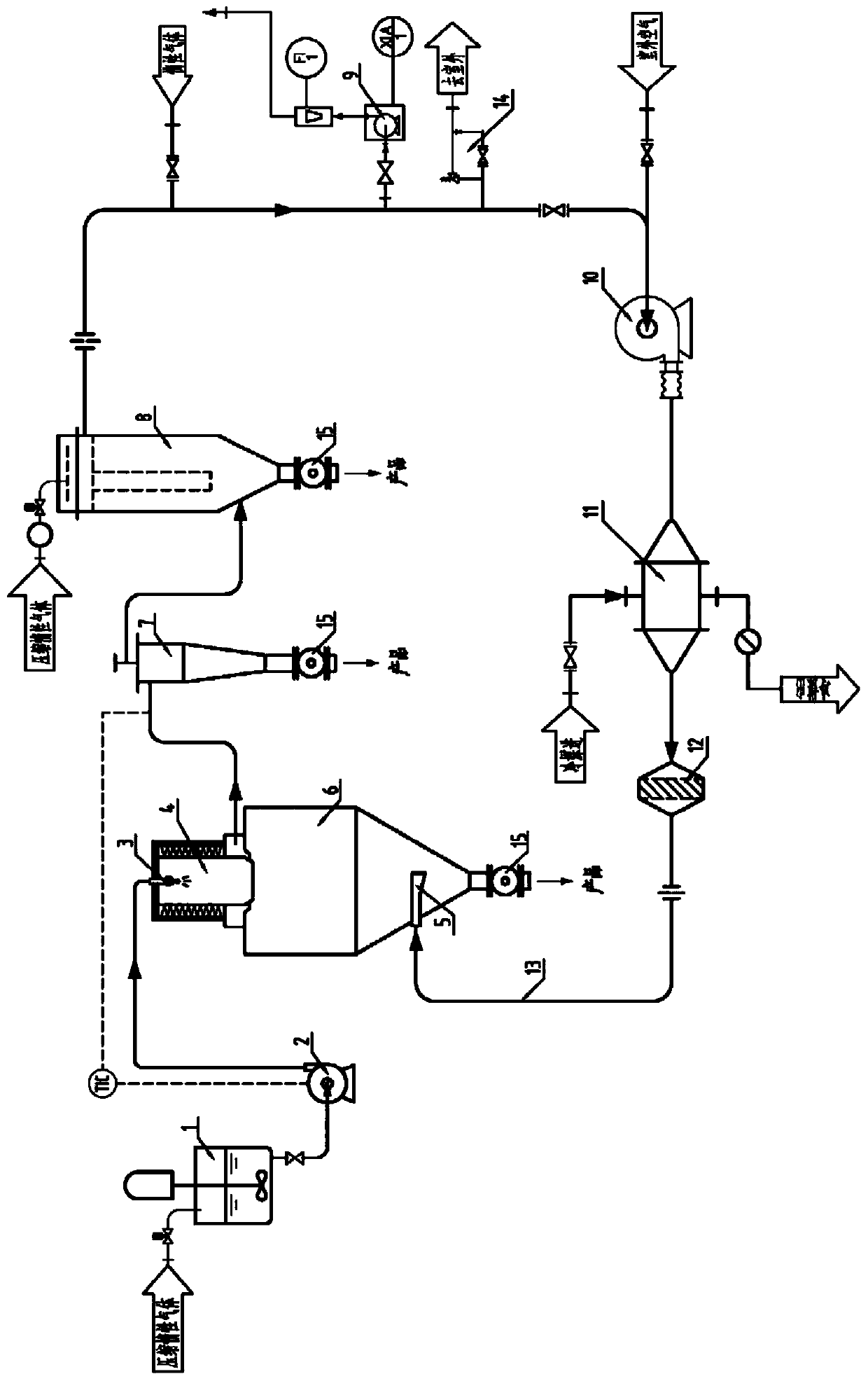

[0042] like figure 1 As shown, the present embodiment provides a spray reaction device for preparing insoluble sulfur in a closed circuit, including a melting system 1, a feeding system, a high-temperature reaction furnace 4, a cooling chamber 6, a separation system, a gas analysis system 9, a cooling system, a pressure A balance system 14 and a discharge system 15; the outlet end of the melting system 1 communicates with the inlet end of the feed system, and the outlet end of the feed system is provided with an atomizing nozzle 3, and the atomizing nozzle 3 It communicates with the high temperature reaction furnace 4, the high temperature reaction furnace 4 communicates with the cooling chamber 6, and the outlet end of the cooling system communicates with the inside of the cooling chamber 6; the cooling chamber 6 The bottom is provided with the discharge system 15, the inlet end of the separation system communicates with the cooling chamber 6, and the gas outlet end of the se...

Embodiment 2

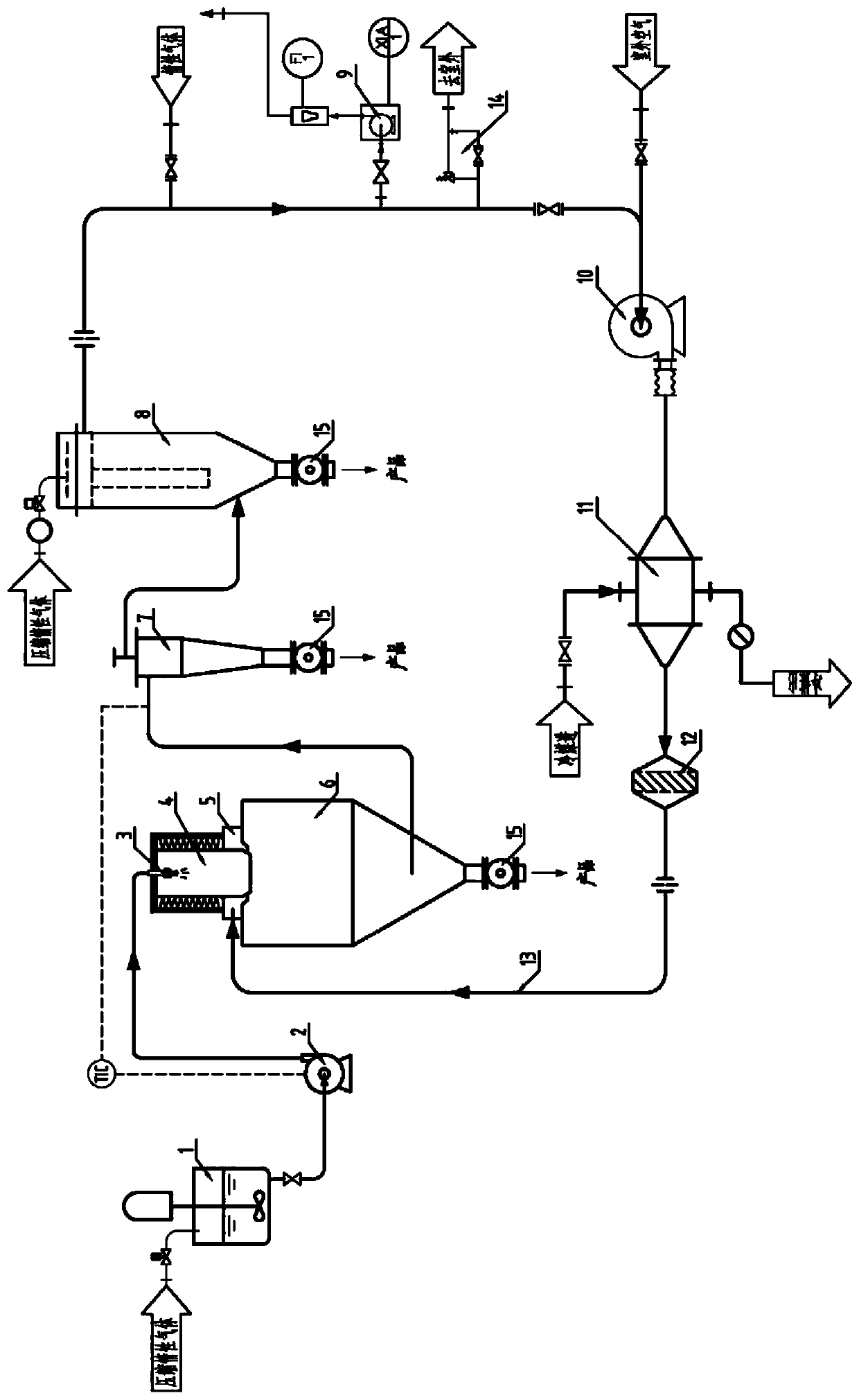

[0053] This embodiment is an embodiment improved on the basis of the first embodiment.

[0054] In this embodiment, the cooling chamber 6 is a box-type structure, a cleaning device is provided at the inner bottom of the box-type structure, the high-temperature reaction furnace 4 is arranged on one side of the cooling chamber 6, and the gas The distributor 5 is arranged between the high temperature reaction furnace 4 and the cooling chamber 6 ; the discharge system 15 is arranged at the bottom of the other side of the cooling chamber 6 . The separation system includes an exhaust gas purifier 8 .

[0055] The cleaning device includes two chains arranged in parallel, the two chains are arranged on both sides of the inner bottom of the box-type structure, and a plurality of scrapers are arranged between the two chains, and the two ends of the scrapers are respectively connected to a The chains on the side are connected, and the chain is driven by a motor. During the rotation of t...

Embodiment 3

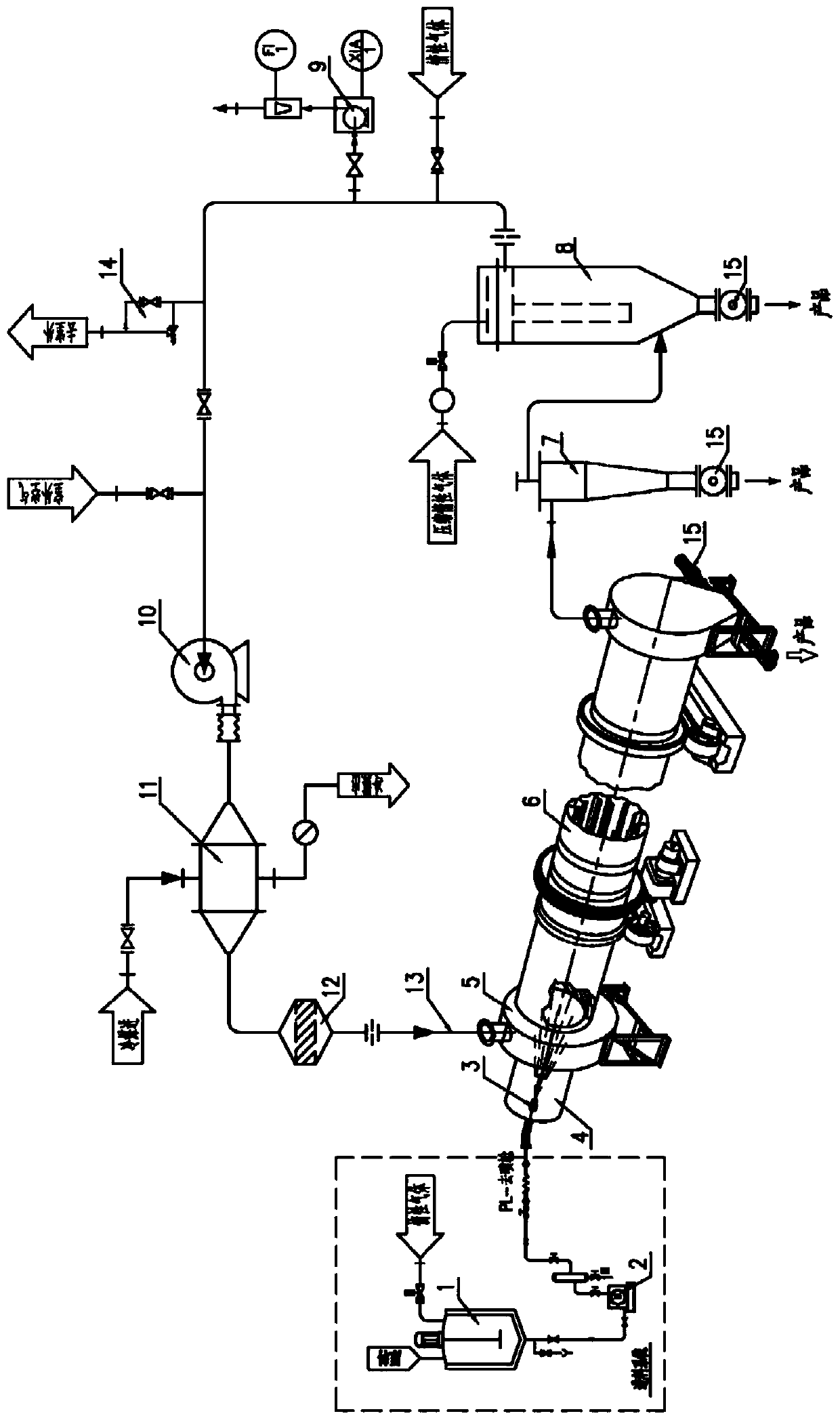

[0059] This embodiment is an embodiment improved on the basis of the first embodiment.

[0060] In this embodiment, the cooling chamber 6 is a cylindrical structure placed horizontally, the high-temperature reaction furnace 4 is arranged on one side of the cooling chamber 6, and the gas distributor 5 is arranged on the high-temperature reaction furnace 4 and the cooling chamber 6 ; the discharge system 15 is arranged at the bottom of the other side of the cooling chamber 6 .

[0061] The separation system includes a separator and an exhaust gas purifier 8, the inlet end of the separator is communicated with the cooling chamber 6, the gas outlet end of the separator is communicated with the exhaust gas purifier 8, the The gas outlet port of the exhaust gas purifier 8 communicates with the inlet port of the fan 10 .

[0062] The cooling chamber 6 also includes a driving transmission mechanism, and the driving transmission mechanism includes a first ring gear and a supporting ci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com