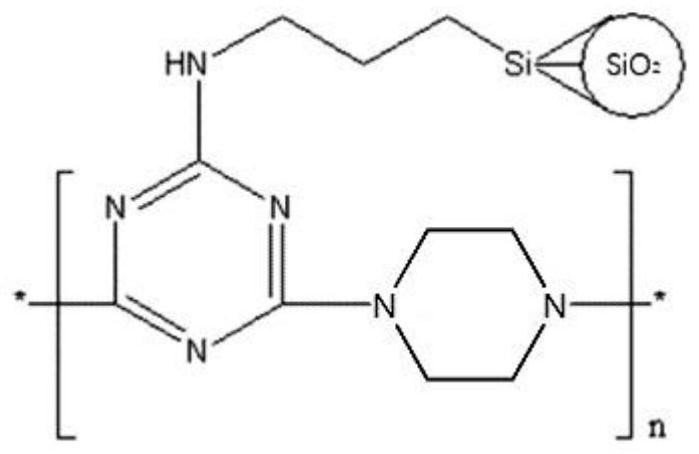

Nano-silica modified macromolecular flame-retardant charring agent and preparation method thereof

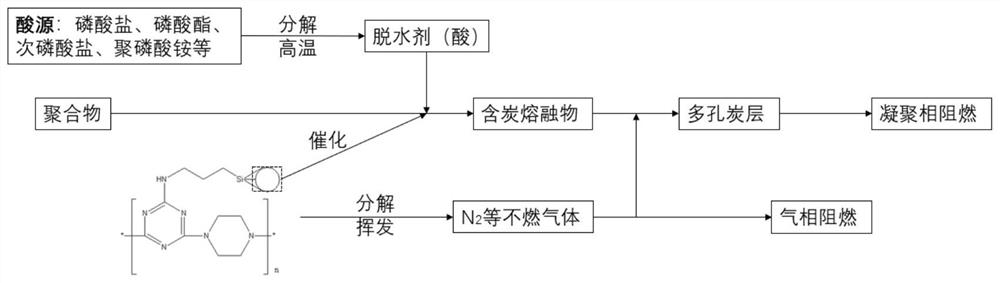

A technology of nano-silica and char-forming agent, which is applied in the field of high-efficiency char-forming agent modified by nano-silica, can solve the problems of affecting the synergistic flame retardant effect of nano-silica and IFR, difficult to disperse uniformly, and poor compatibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

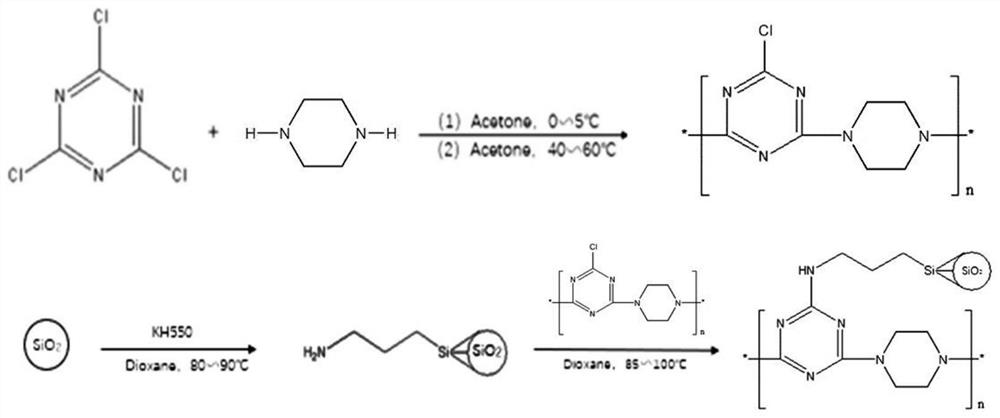

Method used

Image

Examples

Embodiment 1

[0023] (1) Add 18g of cyanuric chloride and 200mL of acetone to a 500mL flask, keep the temperature of the system below 5°C, so that the cyanuric chloride is completely dissolved, and at the same time, dissolve 3.05g of piperazine and 4.00g of sodium hydroxide in 20mL Deionized water was added dropwise into the reaction system within 1.5 hours, and the reaction was maintained at 0-5° C. for 3 hours after the addition was completed. After the reaction finished, the reaction system was warmed up to 45°C, then the aqueous solution of piperazine (3.05g) and sodium hydroxide (4.00g) was added dropwise to the above-mentioned reaction system again, at this temperature, the time and The reaction times were 1.5h and 3h, respectively. Finally, after the synthesized product was left to stand and filtered, it was alternately washed three times with ethanol and deionized water, and dried in a vacuum oven at 70° C. for 12 hours to obtain an intermediate.

[0024](2) Disperse 1g of nano-sil...

Embodiment 2

[0027] (1) Add 18g of cyanuric chloride and 200mL of acetone to a 500mL flask, keep the temperature of the system below 5°C, so that the cyanuric chloride is completely dissolved, and at the same time, dissolve 3.05g of piperazine and 4.00g of sodium hydroxide in 20mL Deionized water was added dropwise into the reaction system within 1.5 hours, and the reaction was maintained at 0-5° C. for 3 hours after the addition was completed. After the reaction finished, the reaction system was warmed up to 45°C, then the aqueous solution of piperazine (3.05g) and sodium hydroxide (4.00g) was added dropwise to the above-mentioned reaction system again, at this temperature, the time and The reaction times were 1.5h and 3h, respectively. Finally, after the synthesized product was left to stand and filtered, it was alternately washed three times with ethanol and deionized water, and dried in a vacuum oven at 70° C. for 12 hours to obtain an intermediate.

[0028] (2) Disperse 1g of nano-si...

Embodiment 3

[0031] (1) Add 18g of cyanuric chloride and 200mL of acetone to a 500mL flask, keep the temperature of the system below 5°C, so that the cyanuric chloride is completely dissolved, and at the same time, dissolve 3.05g of piperazine and 4.00g of sodium hydroxide in 20mL Deionized water was added dropwise into the reaction system within 1.5 hours, and the reaction was maintained at 0-5° C. for 3 hours after the addition was completed. After the reaction finished, the reaction system was warmed up to 45°C, then the aqueous solution of piperazine (3.05g) and sodium hydroxide (4.00g) was added dropwise to the above-mentioned reaction system again, at this temperature, the time and The reaction times were 1.5h and 3h, respectively. Finally, after the synthesized product was left to stand and filtered, it was alternately washed three times with ethanol and deionized water, and dried in a vacuum oven at 70° C. for 12 hours to obtain an intermediate.

[0032] (2) Disperse 1g of nano-si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com