Preparation method of sulfydryl graphene copolymerized mercapto-alkenyl polymer flame-retardant system

A technology of mercapto compounds and graphene, which is applied in the field of compound synthesis, can solve the problems of weak vinyl reactivity, poor migration resistance, and agglomeration, and achieve excellent heat and oxygen insulation capabilities, improved mechanical properties, and high flame retardant efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The preparation method of mercaptographene copolymerized mercapto-ene polymer flame retardant system in the present embodiment comprises the following steps:

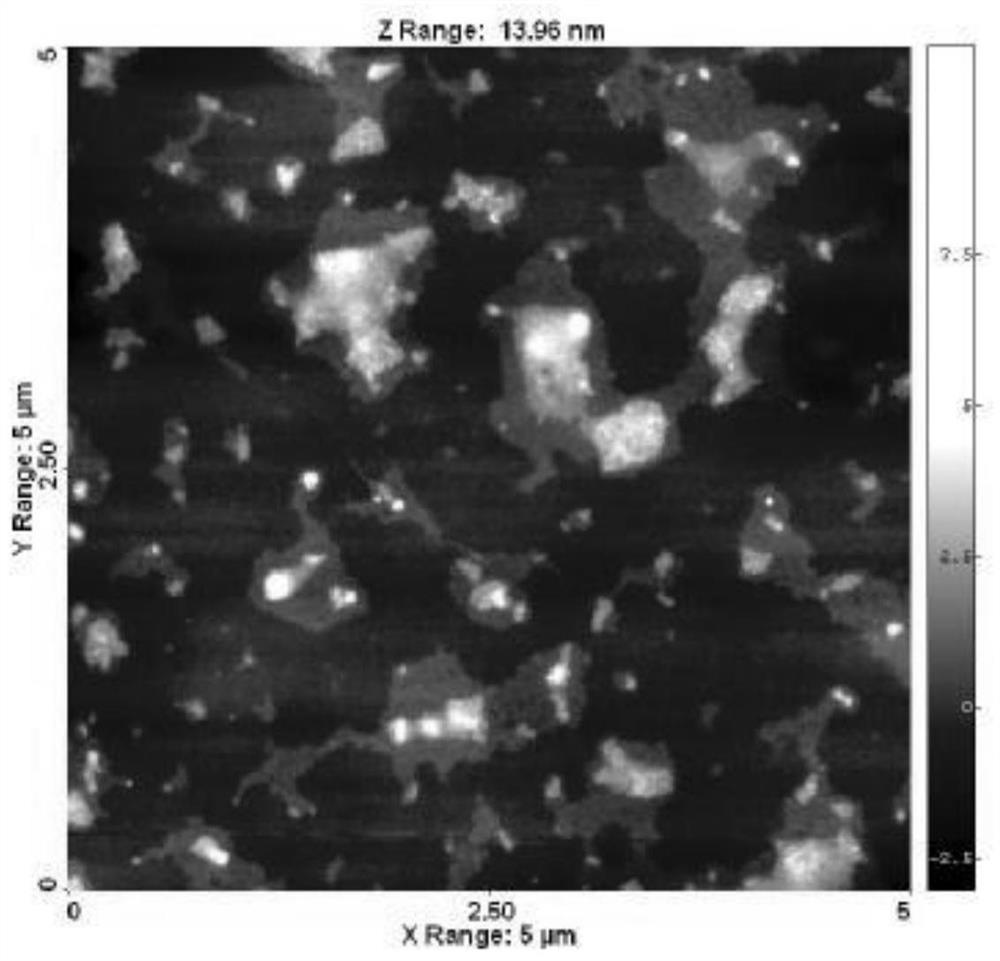

[0030] (1) Synthesis of mercapto graphene

[0031] Dissolve 100 mg of hydroxygraphene in 50 mL of tetrahydrofuran, ultrasonicate for 1 hour, and then add 200 mg of γ-mercaptopropyltrimethoxysilane, 50 mg of N,N'-dicyclohexylcarbodiimide and 1 mL of ammonia water in sequence under nitrogen protection. React at 65°C for 12 hours; after the reaction, wash with methanol and vacuum dry to obtain a mercapto graphene flame retardant, such as figure 1 As shown; graphene is a new material with a single-layer sheet structure composed of carbon atoms, and the surface is very smooth; it can be seen from the AFM image that the surface of graphene grafted with mercapto compounds has a layer structure surface The different colors of light and dark indicate that the surface of graphene becomes rough due to the functionalization...

Embodiment 2

[0035] The preparation method of mercaptographene copolymerized mercapto-ene polymer flame retardant system in the present embodiment comprises the following steps:

[0036] (1) Synthesis of mercapto graphene

[0037] Dissolve 100 mg of hydroxygraphene in 50 mL of ethanol, sonicate for 1 hour, then add 100 mg of 2-mercaptoethyltriethoxysilane, 50 mg of N,N'-dicyclohexylcarbodiimide and 1 mL of Ammonia, react at 65°C for 12 hours. After the reaction is finished, wash with methanol and dry in a vacuum to obtain the mercaptographene flame retardant;

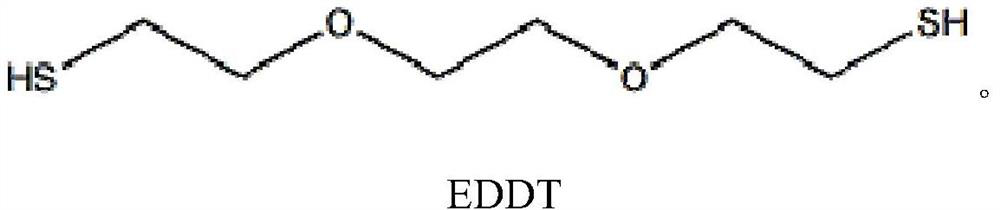

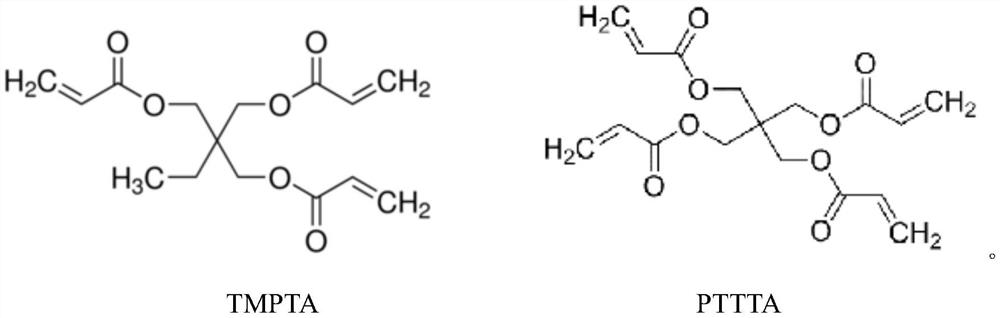

[0038] (2) Preparation of mercapto-ene polymer flame retardant system

[0039] In a four-necked flask equipped with a stirrer and a condenser, add 100g deionized water, 0.1g NP-4, 0.05g AES-A, and stir at a high speed for 30 minutes; then add 10g EDDT, 12g TMPTA, 0.04g step (1 ) the prepared mercapto graphene flame retardant was dispersed in 100g deionized water, slowly and continuously added to the above-mentioned four-necked fl...

Embodiment 3

[0041] The preparation method of mercaptographene copolymerized mercapto-ene polymer flame retardant system in the present embodiment comprises the following steps:

[0042] (1) Synthesis of mercapto graphene

[0043] Dissolve 100 mg of hydroxygraphene in 50 mL of tetrahydrofuran, sonicate for 1 hour, and then add 200 mg of γ-mercaptopropyltrimethoxysilane, 50 mg of N,N'-dicyclohexylcarbodiimide and 1 mL of tetramethyl ammonium hydroxide, and reacted at 65°C for 12 hours. After the reaction is finished, wash with methanol and dry in a vacuum to obtain the mercaptographene flame retardant;

[0044] (2) Preparation of mercapto-ene polymer flame retardant system

[0045]In a four-necked flask equipped with a stirrer and a condenser tube, add 100g deionized water, 0.1g NP-4, 0.05g AES-A, and stir at a high speed for 30 minutes; then add 10g EDDT, 10g PTTTA, 0.2g step (1 ) the prepared mercapto graphene flame retardant was dispersed in 100g deionized water, slowly and continuous...

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com