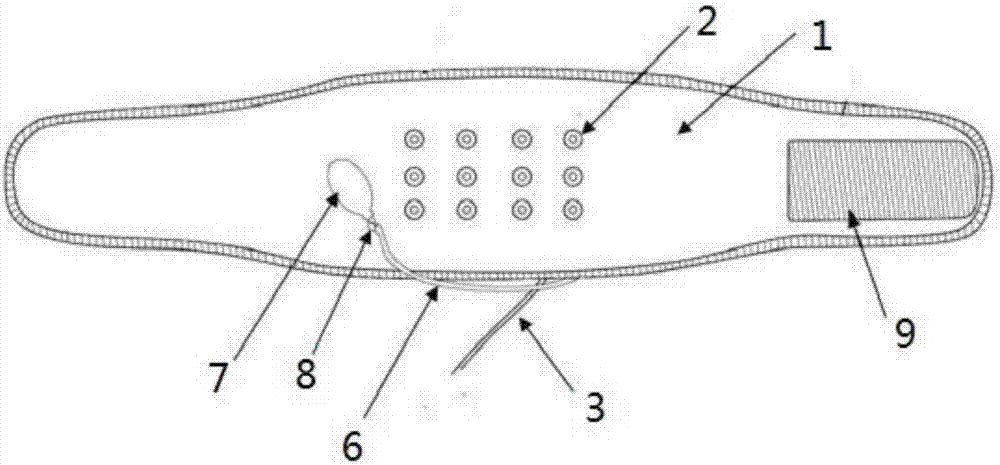

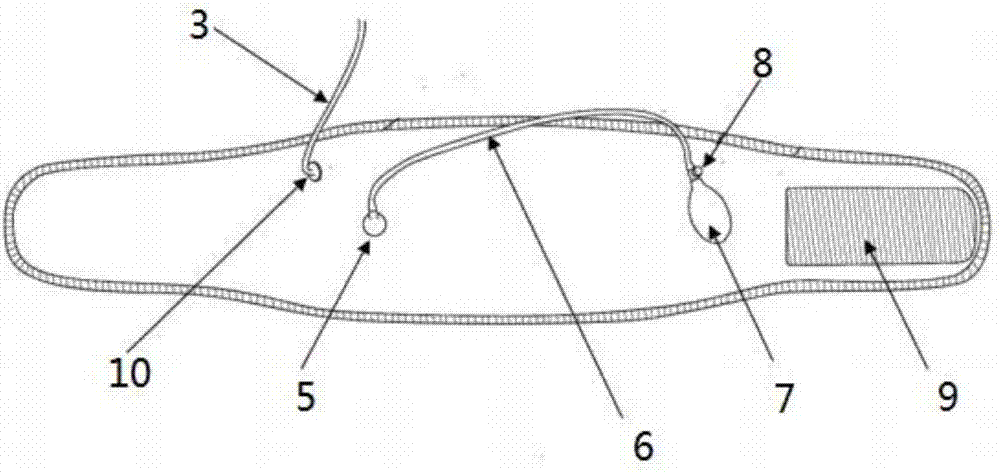

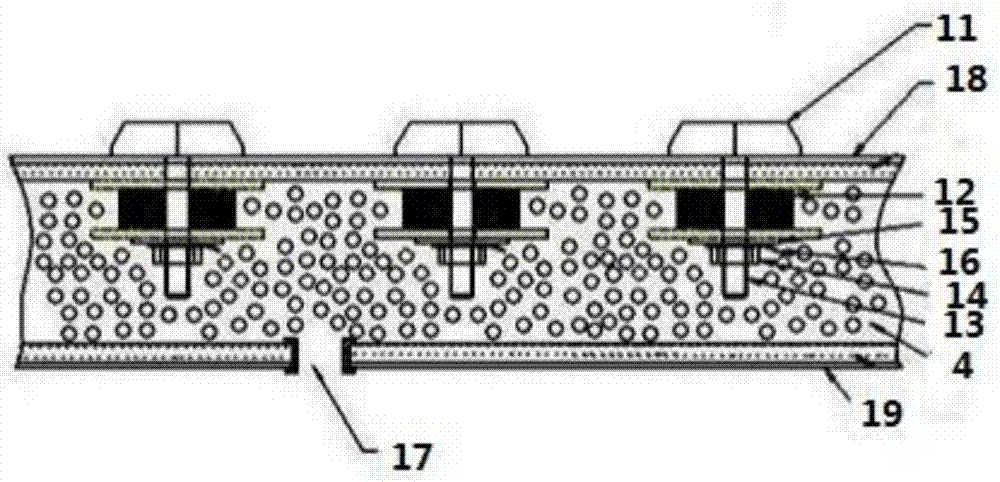

PVC flexible pipe for low-frequency electromagnetic physiotherapy pad, preparation method of PVC flexible pipe, and electromagnetic physiotherapy pad

A technology of electromagnetic physiotherapy and physiotherapy pads, which is applied in the medical field to achieve the effect of improving pathological conditions, changing morbid environments, and simple processing and molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1, a kind of PVC hose for low-frequency electromagnetic physiotherapy pad

[0039] The PVC hose described in Example 1 of the present invention is made from the following preparation raw materials in parts by weight: 80 parts of PVC resin, 1.5 parts of mercaptan methyl tin, 2 parts of hexamethylphosphoric triamide, and 2 parts of epoxy soybean oil and 30 parts of a plasticizer; the plasticizer is composed of acetyl tri-n-butyl citrate and O-acetyl ricinoleic acid methyl ester in a weight ratio of 1:0.02.

[0040] Preparation:

[0041] Mix PVC resin, hexamethylphosphoric triamide, epoxidized soybean oil and plasticizer evenly, stir at 95°C for 20 minutes, add mercaptan methyl after cooling to room temperature, continue stirring for 10 minutes, and then add to the twin-screw extruder Melting, plasticizing, extruding, granulating, that is.

Embodiment 2

[0042] Embodiment 2, a PVC hose for low-frequency electromagnetic physiotherapy pad

[0043] The PVC hose described in Example 2 of the present invention is made from the following preparation raw materials in parts by weight: 50 parts of PVC resin, 0.2 part of mercaptan methyl tin, 1 part of hexamethylphosphoric triamide, and 1 part of epoxy soybean oil , 20 parts of a plasticizer and 0.3 part of nanocrystalline cellulose; the plasticizer is composed of acetyl tri-n-butyl citrate and O-acetyl ricinoleic acid methyl ester in a weight ratio of 1:0.01.

[0044] Preparation method: Mix PVC resin, hexamethylphosphoric triamide, epoxidized soybean oil and plasticizer evenly, stir at 95°C for 20 minutes, cool to room temperature, add mercaptan methyl and nanocrystalline cellulose, and continue stirring for 10 minutes Then add it to a twin-screw extruder to melt, plasticize, extrude, and granulate.

Embodiment 3

[0045] Embodiment 3, a PVC hose for low-frequency electromagnetic physiotherapy pad

[0046] The PVC hose described in Example 3 of the present invention is made of the following raw materials in parts by weight: 100 parts of PVC resin, 1 part of mercaptan methyl tin, 3 parts of hexamethylphosphoric triamide, and 3 parts of epoxidized soybean oil and 40 parts of a plasticizer; the plasticizer consists of acetyl tri-n-butyl citrate and O-acetyl ricinoleic acid methyl ester in a weight ratio of 1:0.06.

[0047] The preparation method is as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com