A non-droplet, water-stained, halogen-free flame-retardant polyurethane resin and its application

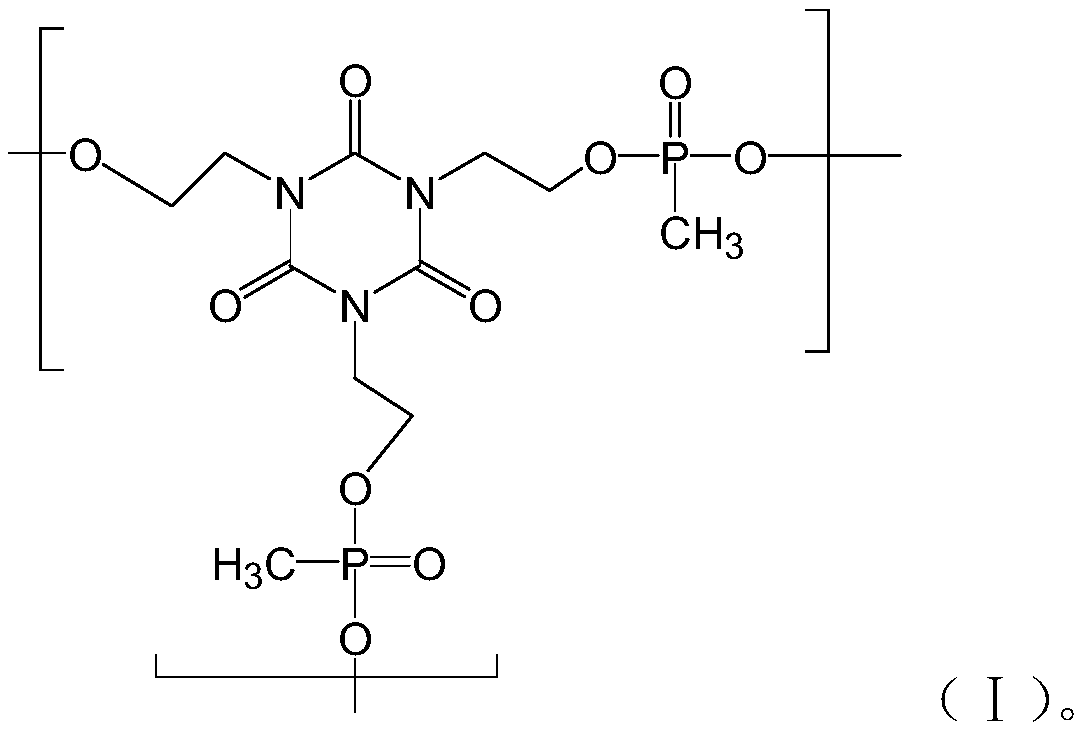

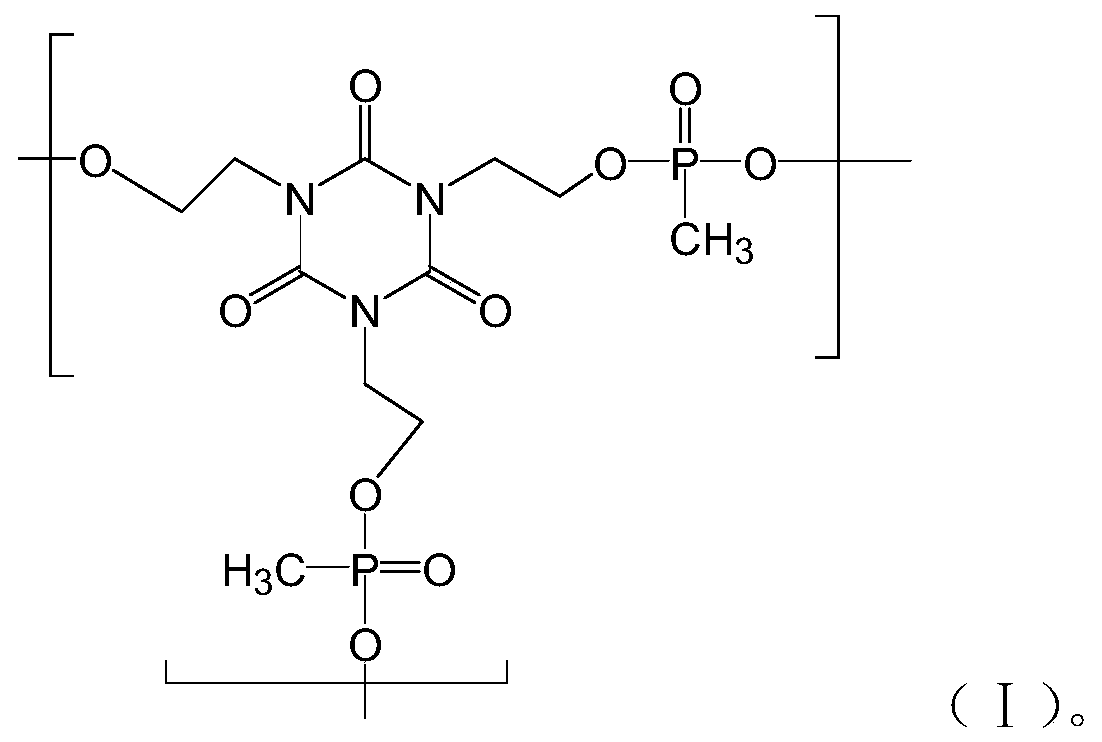

A kind of polyurethane resin and polyurethane technology, applied in the application of halogen-free flame-retardant polyurethane leather, no molten drop, no water stain, halogen-free flame-retardant polyurethane resin field, can solve the problems of drop, drip, easy migration and precipitation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Polyurethane leather was prepared and characterized as follows:

[0055] (1) Prepare the flame retardant polyurethane resin composition after blending each raw material through the following formula (if there is no special statement, the proportions in the present invention are all percentages by weight):

[0056] Polyurethane system 82%;

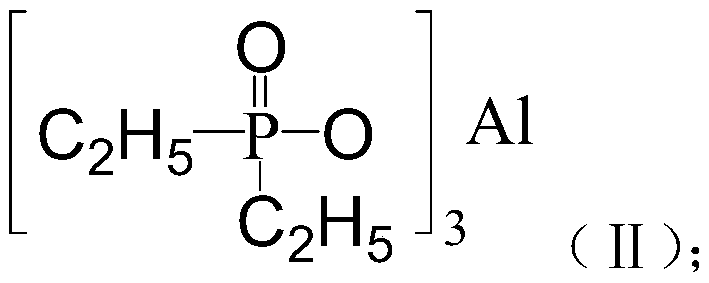

[0057] Aluminum diethyl hypophosphite 13%;

[0058] Carbon-forming components 5%;

[0059] Wherein, by weight, the composition of the polyurethane system is:

[0060]

[0061] (2) Coat the flame-retardant polyurethane resin composition prepared in step (1) on the polyester warp-knitted fabric to form a coating with a thickness of 250um, dry and solidify it in a drier at 120°C for 3 minutes, and Pressing and aging at 40° C. for 72 hours to obtain flame-retardant synthetic leather.

[0062] (3) Test related performance.

[0063] The preparation technology of carbon-forming component in the present embodiment is as follows:

[...

Embodiment 2

[0071] The implementation process is the same as in Example 1, except that the ratio of aluminum diethyl hypophosphite and carbon-forming components is adjusted, the ratio of diethyl hypophosphite is increased, and the total amount of the flame retardant system remains unchanged. Other materials and proportioning are shown in Table 1, and the obtained material results are shown in Table 1.

Embodiment 3

[0073] The implementation process is the same as in Example 1, except that the ratio of aluminum diethyl hypophosphite and carbon-forming components is adjusted, the ratio of carbon-forming components is increased, and the total amount of the flame-retardant system is kept unchanged. Other materials and proportioning are shown in Table 1, and the obtained material results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com