Composite hydroxide smoke suppression type flame retardant as well as preparation method and application thereof

A composite hydroxide and hydroxide technology, applied in the chemical and material fields, can solve the problems of poor compatibility of matrix resins, low flame retardant efficiency, etc., and achieve the effects of high stability and improved char formation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

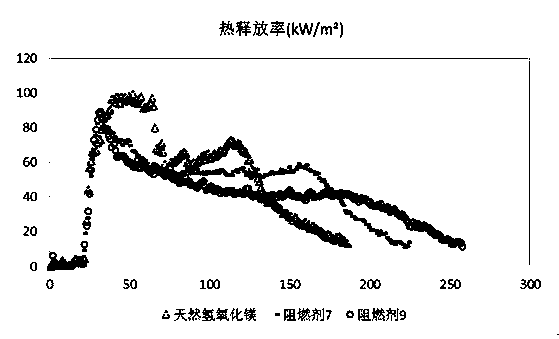

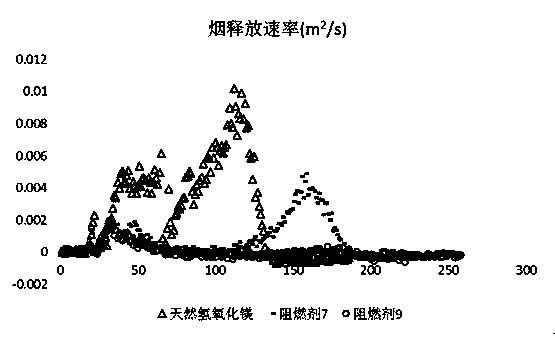

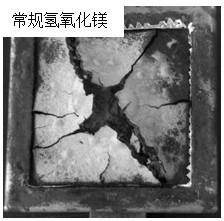

Image

Examples

preparation example Construction

[0033] The preparation method of the composite hydroxide smoke-suppressing flame retardant includes the first method of a fluidized bed equipment method or the second method of a grinding method.

[0034] The first method: the fluidized bed equipment method is that the reaction temperature of the fluidized bed equipment is 65~95°C, the coupling agent is sprayed in through the nozzle, and the reaction time is 30~60min. When the material temperature reaches the reaction temperature, the coupling agent is added, and the coupling agent is The alkoxy group of the coupling agent is hydrolyzed and then condensed, and part of its hydroxyl group reacts with the calcium hydroxide in the hydroxide, and partly reacts with the magnesium hydroxide in the hydroxide, so that the two form an effective chemical coupling bond.

[0035] Described method two: grinding method comprises the steps:

[0036] Step 1: Prepare magnesium hydroxide and calcium hydroxide in a molar ratio of 98.5:1.5~75:25 t...

Embodiment 1

[0051] Flame retardant 1: The molar ratio of magnesium hydroxide to calcium hydroxide is 98:2, magnesium hydroxide is chemical magnesium hydroxide, particle size is 1.5 μm, and calcium hydroxide particle size is 3 μm. The preparation method of the smoke-suppressing flame retardant is Method 1, the coupling agent is vinyl silane coupling agent, the coupling reaction temperature is 70°C, and the coupling reaction time is 35 minutes.

Embodiment 2

[0053] Flame retardant 2: The molar ratio of magnesium hydroxide to calcium hydroxide is 88:12, the magnesium hydroxide is chemical magnesium hydroxide, the particle size is 1.5 μm, and the calcium hydroxide particle size is 10 μm. The preparation method of the smoke-suppressing flame retardant is Method 1, the coupling agent is vinyl silane coupling agent, the coupling reaction temperature is 80°C, and the coupling reaction time is 45 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com