Anti-pre-crosslinking rapid-solidification low-smoke zero-halogen flame-retardant silane crosslinking nano-modified polyolefin composition

An anti-pre-crosslinking and nano-modification technology, applied in the direction of plastic/resin/wax insulators, organic insulators, etc., can solve the requirements of high grafting reaction equipment and process conditions, flame retardants are easy to absorb moisture and water, and product processing flow Improve the mechanical and mechanical properties and flame retardant properties, good wettability and dispersion peeling performance, and improve processing fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

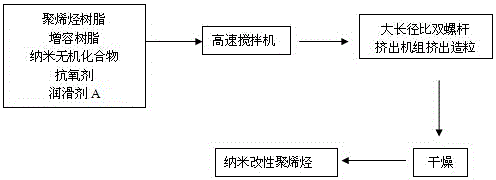

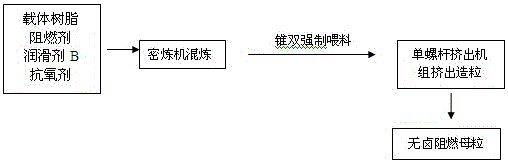

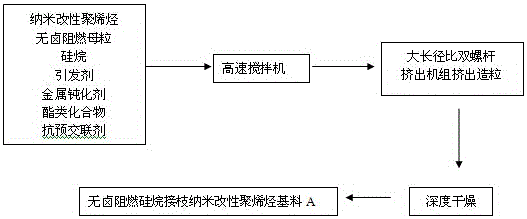

[0028] 1) Preparation of nano-modified polyolefin: the mass ratio of ethylene-1-octene copolymer ENGAGE8200, low-density polyethylene DJ210, linear low-density polyethylene DFDA7042 and ethylene-vinyl acetate copolymer EVA240W is 5.0:1.0: 1.0: 100 parts of the mixture of 3.0, grafting monomer content is 10 parts of ethylene-1-octene copolymer maleic anhydride grafts of 1.5wt%, organic montmorillonite NanomerI.44PSS4.0 parts, four [?- (3,5-di-tert-butyl-4-hydroxyphenyl)propionic acid]pentaerythritol and tris(2,4-di-tert-butylphenyl)phosphite in a mass ratio of 2:1 0.2 parts , polyethylene wax and fluoroelastomer with a mass ratio of 5:1, put 0.5 parts of the compound into a high-speed mixer, stir at a speed of 430-475 rpm for 3 minutes at room temperature, and then discharge the material with a The large aspect ratio of the threaded section is extruded and granulated by the twin-screw extruder. The length-to-diameter ratio L / D of the twin-screw extruder is 44, and the extrusio...

Embodiment 2

[0034] 1) Preparation of nano-modified polyolefin: the mass ratio of ethylene-1-octene copolymer ENGAGE8200, low-density polyethylene DJ210, linear low-density polyethylene DFDA7042 and ethylene-vinyl acetate copolymer EVA240W is 7.0:1.0: 3.0: 100 parts of the mixture of 4.0, graft monomer content is 12 parts of ethylene-1-octene copolymer maleic anhydride grafts of 1.5wt%, organic montmorillonite NanomerI.44PSS6.0 parts, four [?- (3,5-di-tert-butyl-4-hydroxyphenyl)propionic acid]pentaerythritol and tris(2,4-di-tert-butylphenyl)phosphite in a mass ratio of 2:1 mixture 0.4 parts , polyethylene wax and fluoroelastomer with a mass ratio of 5:1 compound 0.8 parts, put into a high-speed mixer, and then extrude and pelletize with a large length-to-diameter ratio twin-screw extruder with a reverse thread section.

[0035] 2) Preparation of halogen-free flame retardant masterbatch: 100 parts of magnesium hydroxide Martin H5IV, 25 parts of a mixture of ethylene-1-octene copolymer ENGAG...

Embodiment 3

[0041] 1) Preparation of nano-modified polyolefin: the mass ratio of ethylene-1-octene copolymer ENGAGE8200, low-density polyethylene DJ210, linear low-density polyethylene DFDA7042 and ethylene-vinyl acetate copolymer EVA240W is 10:1.0: 5.0: 100 parts of the mixture of 5.0, graft monomer content is 15 parts of ethylene-1-octene copolymer maleic anhydride grafts of 1.5wt%, organic montmorillonite NanomerI.44PSS8.0 parts, four [?- (3,5-di-tert-butyl-4-hydroxyphenyl)propionic acid]pentaerythritol and tris(2,4-di-tert-butylphenyl)phosphite in a mass ratio of 2:1 mixture 0.6 parts 1.0 parts of the compound of polyethylene wax and fluoroelastomer with a mass ratio of 5:1 is put into a high-speed mixer, and then extruded and pelletized with a large length-to-diameter ratio twin-screw extruder with a reverse thread section.

[0042] 2) Preparation of halogen-free flame retardant masterbatch: 100 parts of magnesium hydroxide Martin H5IV, 30 parts of a mixture of ethylene-1-octene copo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com