Preparation method of graphene modified flame-retardant waterborne polyurethane coating and adhesive

A water-based polyurethane, graphene modification technology, applied in the direction of polyurea/polyurethane coatings, polyurea/polyurethane adhesives, adhesives, etc. The effect of releasing and suppressing the spread of flames

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

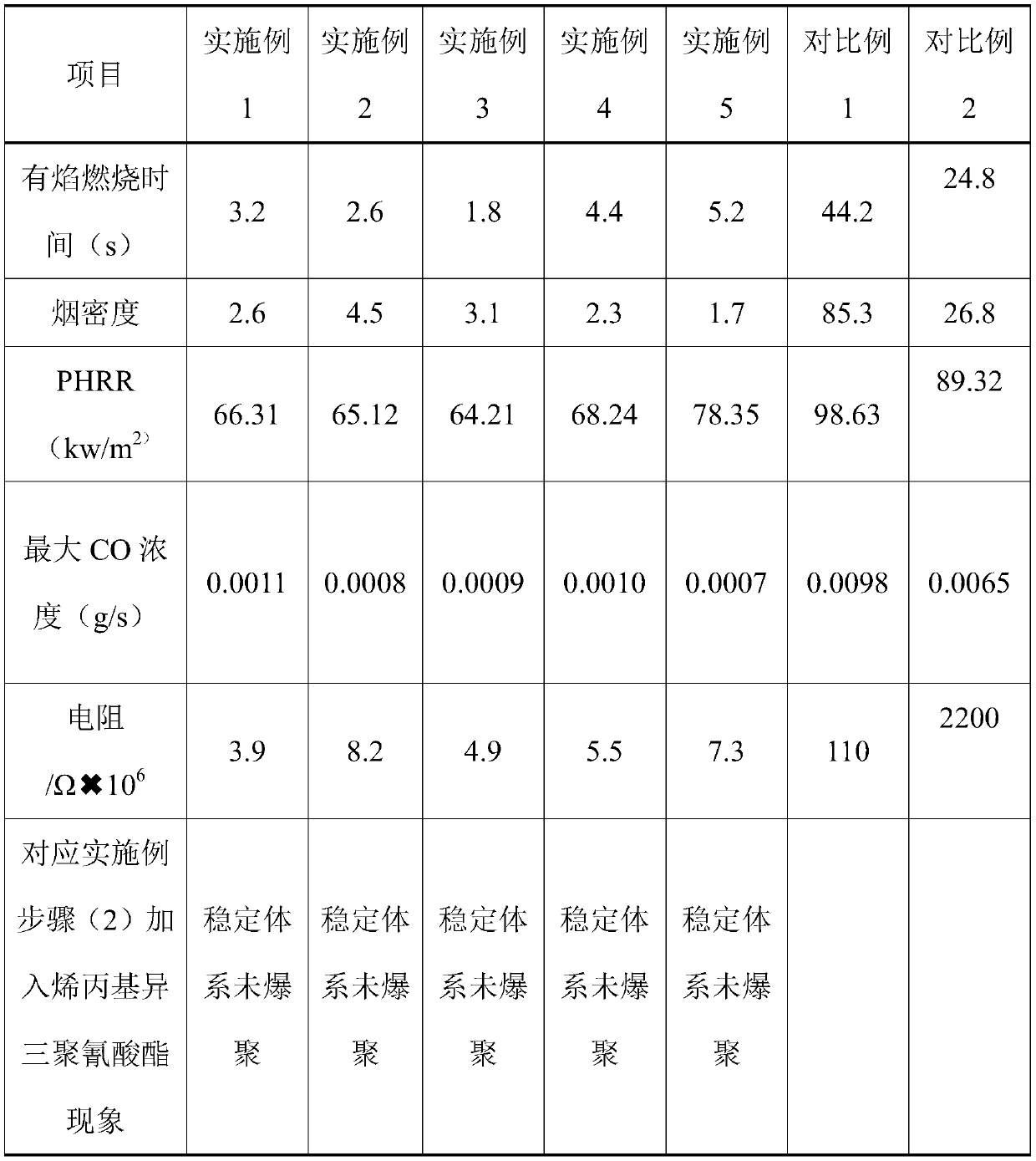

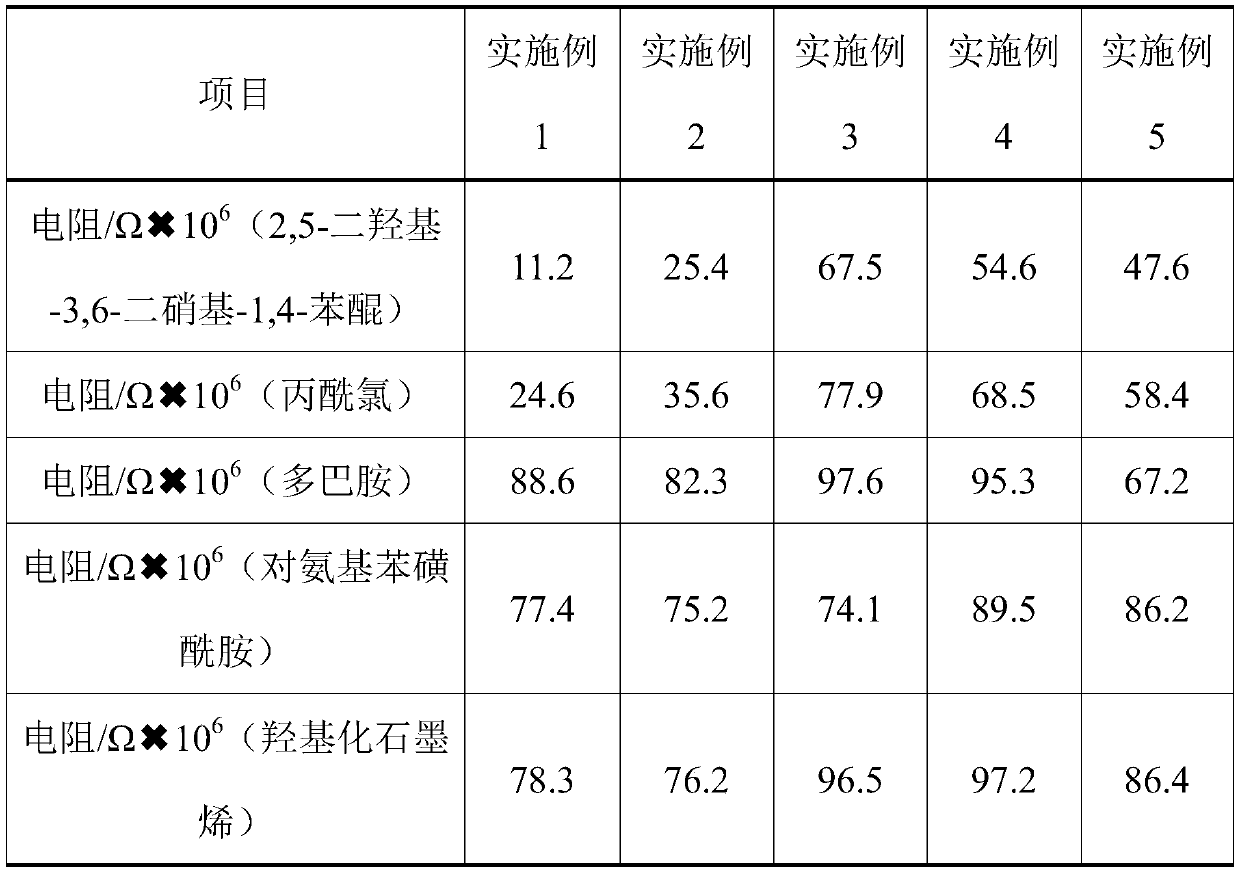

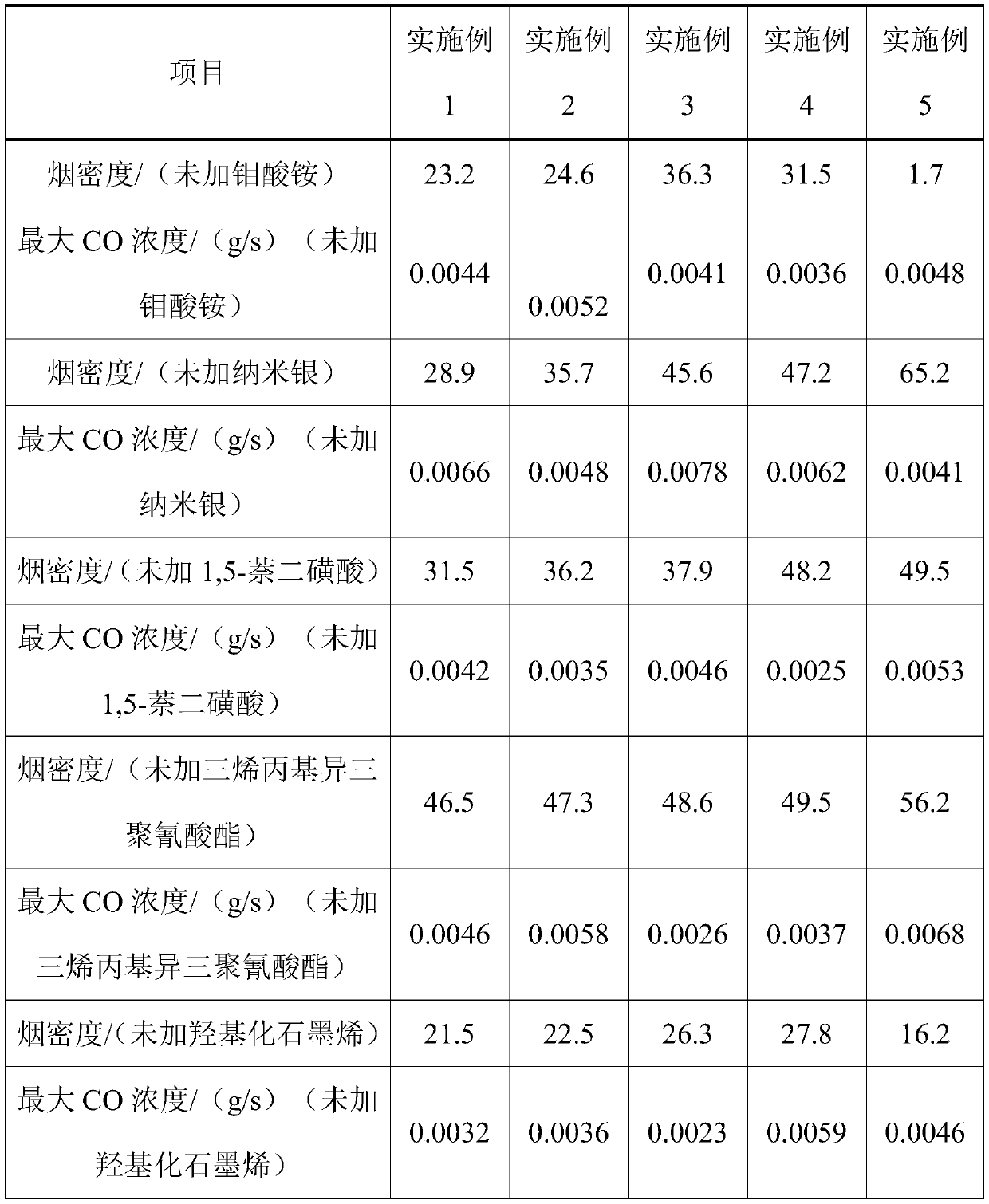

Embodiment 1

[0035] (1) Preparation of MOFs: Add 12g of ammonium molybdate, 0.6g of nano-silver, and 1.6g of 1,5-naphthalene disulfonic acid to 20g of terephthalic acid and 60g of deionized water, and stir at 50°C for 30min. Transfer the obtained liquid to an autoclave, stir and react at 180°C for 2h, filter, wash once with 80ml of water to obtain a powder, and dry in an oven at 80°C for 24h;

[0036] (2) Preparation of flame retardant MOFs composite: Add 60g of dimethyl phosphite into the reaction vessel, then add 1.2g of sodium methoxide and heat up to 75°C, after all the sodium methoxide is dissolved, add 65g of acrylamide and triene Propyl isocyanurate 0.1g, allyl triisopropyl silane 0.4g, propylene hydroxamic acid 0.1g, diethyl malonate 0.2g, lower the temperature to 50°C, keep stirring for 2 hours to obtain the intermediate ; Add 3.2g of MOFs and 0.05g of hydroxylated graphene to the intermediate, react at 60°C for 0.5h, then add 2,5-dihydroxy-3,6-dinitro-1, 0.1g of 4-benzoquinone, ...

Embodiment 2

[0043] (1) Preparation of MOFs: Add 14 g of ammonium molybdate, 0.7 g of nano-silver, and 3.4 g of 1,5-naphthalene disulfonic acid to 20 g of terephthalic acid and 60 g of deionized water, and stir at 60°C for 60 min. The obtained liquid was transferred to an autoclave, stirred and reacted at 200°C for 3h, filtered, washed with 80ml of water once to obtain a powder, and dried in an oven at 80°C for 24h;

[0044] (2) Preparation of flame retardant MOFs composite: Add 60 g of dimethyl phosphite into the reaction vessel, then add 1.8 g of sodium methoxide and raise the temperature to 95°C. After all the sodium methoxide is dissolved, add 85 g of acrylamide and triene 0.7g of propyl isocyanurate, 0.7g of allyltriisopropylsilane, 0.6g of propylene hydroxamic acid, 0.3g of diethyl malonate, lower the temperature to 70°C, keep stirring for 5h to obtain the intermediate ; Add 4.6g of MOFs obtained in step (1) and 0.1g of hydroxylated graphene to the intermediate, react at 90°C for 1.5...

Embodiment 3

[0051] (1) Preparation of MOFs: Add 13g of ammonium molybdate, 0.65g of nano-silver, and 2.5g of 1,5-naphthalene disulfonic acid to 20g of terephthalic acid and 60g of deionized water, and stir at 55°C for 45min. The obtained liquid was transferred to an autoclave, treated at 190°C for 2.5h, filtered, washed once with 80ml of water to obtain a powder, and dried in an oven at 80°C for 24h;

[0052] (2) Preparation of flame retardant MOFs composite: Add 60g of dimethyl phosphite into the reaction vessel, then add 1.5g of sodium methoxide and heat up to 85°C, after all the sodium methoxide is dissolved, add 75g of acrylamide and triene 0.55g of propyl isocyanurate, 0.55g of allyltriisopropylsilane, 0.35g of propylene hydroxamic acid, 0.25g of diethyl malonate, lower the temperature to 60°C, keep stirring for 3.5h to obtain intermediate body; add 3.9g of MOFs obtained in step (1) and 0.075g of hydroxylated graphene to the intermediate, react at 75°C for 1h, then add 2,5-dihydroxy-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com