Hydroxymethylated melamino-formaldehyde resin, preparation method and application thereof

A technology of methylolated melamine and formaldehyde resin, which is applied in the field of preparation of methylolated melamine-formaldehyde resin powder, can solve the problem of reducing the methylol content of methylolamine resin, difficult to separate methylolamine resin, and high yield Only 30% of the problem, to achieve the effect of enhancing mechanical properties, easy to popularize, and suppress droplet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

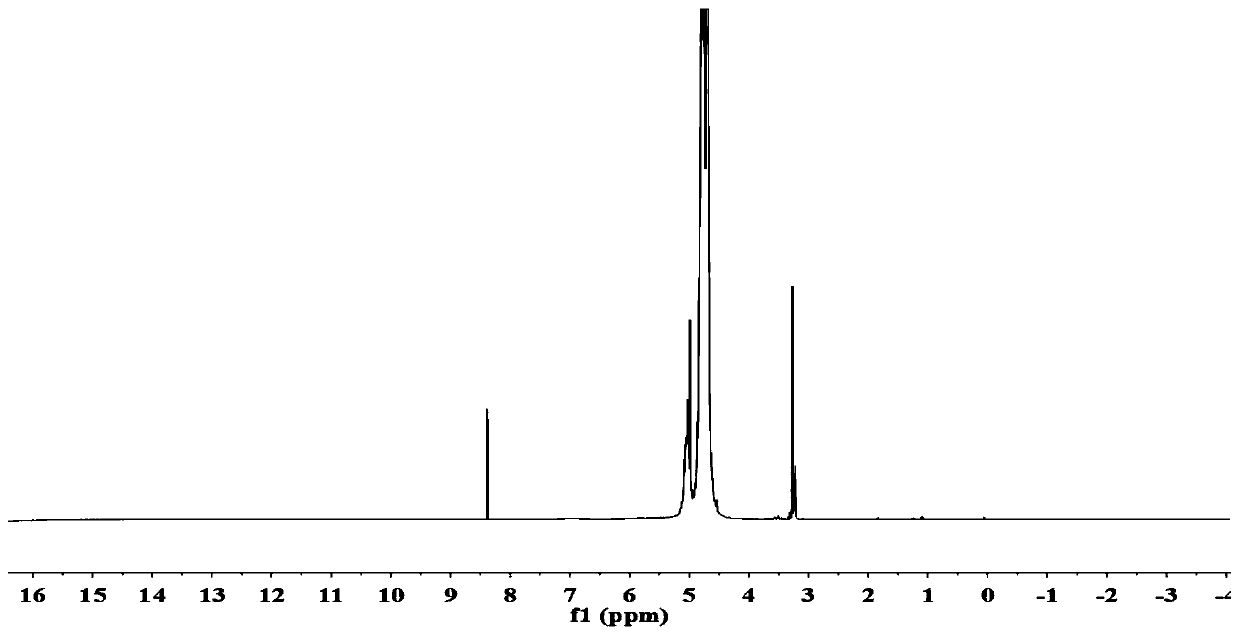

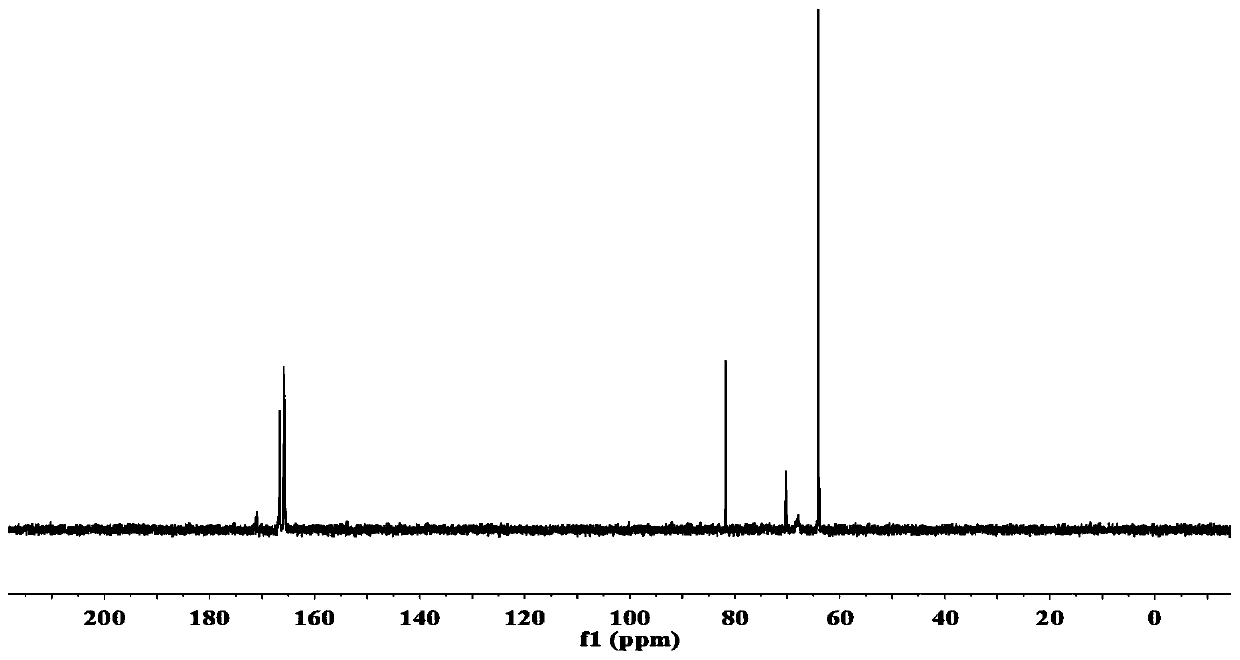

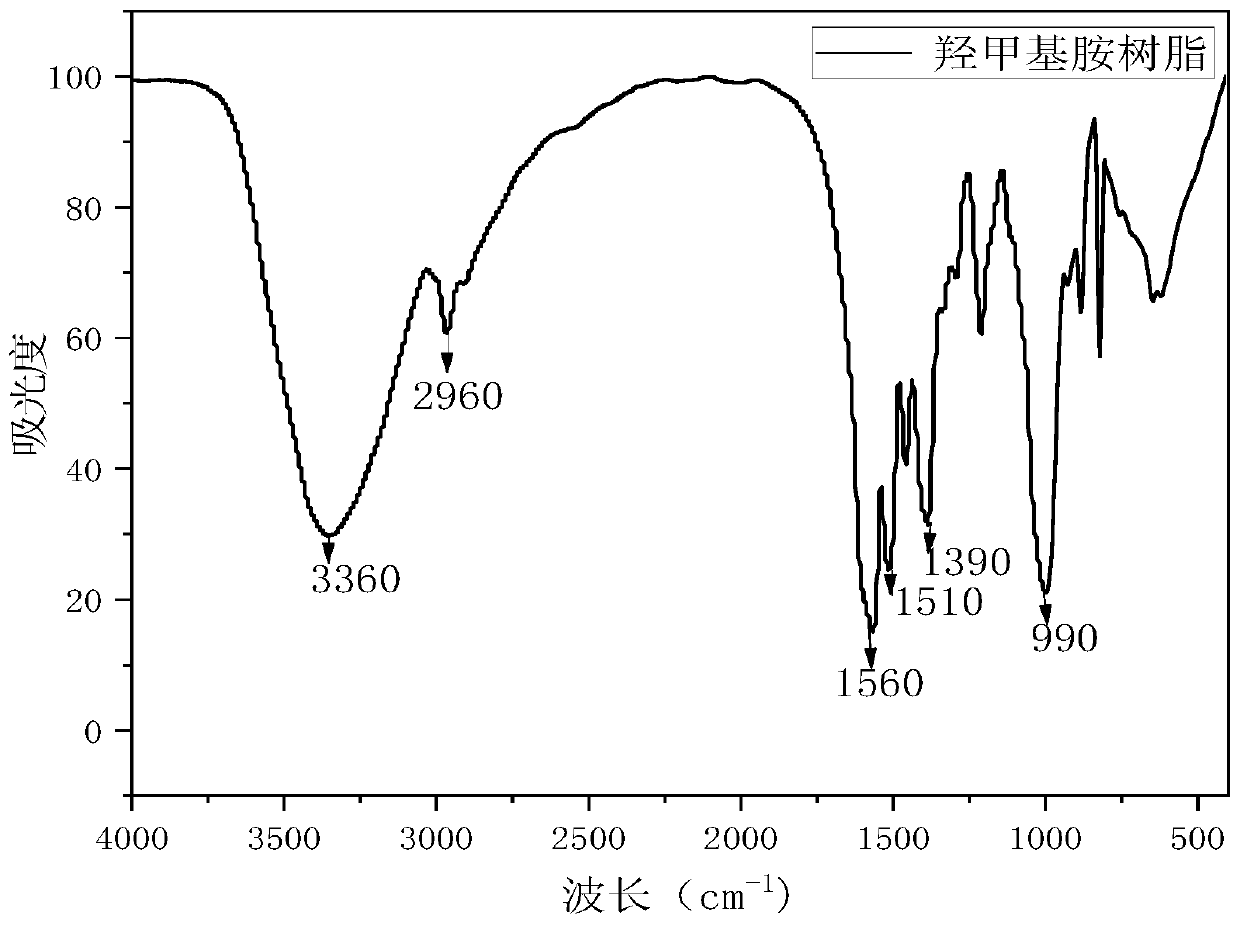

[0031] The first technical problem to be solved in the present invention is to provide a method for preparing methylolated melamine formaldehyde resin powder with high methylol content and high yield. The preparation process comprises the following steps:

[0032] (1) First add melamine and 37% formaldehyde solution into the reaction flask at a molar ratio of 1:2 to 1:7, then add distilled water to keep the theoretical solid content at 10 to 50%; then, control the reaction temperature to 40°C ~95°C, stir and react for 0.5~6h. The whole reaction process needs to use alkali solution to control the pH value of the system to be 8-11;

[0033] (2) After the reaction is over, put the reaction solution into a quick-freezing refrigerator or liquid nitrogen, and freeze it into solid ice cubes;

[0034] (3) Then, freeze-dry or supercritically dry the solid ice cubes; obtain methylolated melamine-formaldehyde resin powder with a yield as high as 95%.

Embodiment 1

[0037] Add 126g (1mol) of melamine and 243g (3mol) of 37% formaldehyde solution into the reaction flask, then add 864g of distilled water to make its theoretical solid content 20%; then, use 10% mass concentration of sodium hydroxide solution to adjust the pH value of the solution , keep the pH value of the whole reaction process at 9; stop the reaction after reacting at 85° C. for 1.5 h, quickly freeze the reaction solution into ice cubes, and freeze-dry to obtain methylolated melamine formaldehyde resin powder. The actual solid content of the obtained methylolated melamine formaldehyde resin (solid content=methylolated melamine resin powder / hydroxylated melamine resin solution) is 19.5%, the yield is 98%, the initial decomposition temperature is 148 ° C, and the storage stability after redissolving up to 60 days.

Embodiment 2

[0039] Add 63g (0.5mol) of melamine and 243g (3mol) of 37% formaldehyde solution into the reaction flask, then add 612g of distilled water to make its theoretical solid content 20%; then, use 10% mass concentration of sodium hydroxide solution to adjust the pH of the solution Value, keep the pH value of the whole reaction process at 9; stop the reaction after reacting at 85°C for 1.5h, freeze the reaction solution into ice cubes, and freeze-dry to obtain methylolated melamine formaldehyde resin powder. The actual solid content is 18.7%, the yield is 96%, the initial decomposition temperature is 98°C, and the storage stability after reconstitution reaches 10 days.

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

| storage stability | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com