Expansive type dripping-resistant flame retardant and preparation method thereof

An intumescent flame retardant and flame retardant technology, which is applied in the field of polymer chemical flame retardants, can solve problems such as low temperature resistance, large influence on material mechanical properties, and large amount of flame retardants, so as to achieve good flame retardant effect , little impact on the mechanical properties of the material, and high flame retardant efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] Take 1.9Kg of ethylene glycol, 2.2Kg of hydroxymethylphenylphosphorous acid and 2.5Kg of 2-carboxyethylphenylphosphorous acid into the reaction kettle, raise the temperature to 80°C, blow in nitrogen, and esterify at 140°C for 3~ 5h, then react under reduced pressure at 160°C and -0.01~-0.096MPa for 3~6h, the esterification rate is above 99%, stop the reaction when no fraction is produced, cool down to 120°C, and discharge to obtain flame retardant esterification liquid.

[0064] Based on the mass of the flame retardant esterification solution, take 4.3Kg of the flame retardant esterification solution, 1.14Kg of hexamethylenediamine and 3.6kg of ethanol into the reaction kettle, raise the temperature to 60°C, blow in nitrogen, and react at 120°C for 3~5h , and then react under reduced pressure at -0.01~-0.096MPa for 3~6h, when the solid content is about 82%, stop the reaction to obtain an intumescent flame retardant.

[0065] Calculated based on the mass of the intumes...

Embodiment 2

[0067] Take 1.53Kg of ethylene glycol and 3.9Kg of hydroxyethylphenyl hypophosphorous acid into the reaction kettle, raise the temperature to 80°C, blow in nitrogen, and esterify at 100°C for 3~5h, then at 160°C, -0.01~-0.096MPa Reaction under reduced pressure for 3~6 hours, the esterification rate is above 99%, stop the reaction when no distillate is produced, lower the temperature to 120°C, discharge the material, and obtain a flame retardant esterification liquid.

[0068] Based on the mass of the flame retardant esterification solution, take 3.9Kg of the flame retardant esterification solution, 0.55Kg of ethylenediamine and 2.8kg of ethanol into the reaction kettle, raise the temperature to 60°C, blow in nitrogen, and react at 120°C for 3~5h , and then react under reduced pressure at -0.01~-0.096MPa for 3~6h, when the solid content is 90%, stop the reaction to obtain an intumescent flame retardant.

[0069] Based on the mass of the intumescent flame retardant, add 2% of...

Embodiment 3

[0072] Take 0.72Kg of ethylene glycol and 1.65Kg of hydroxymethylphenyl hypophosphorous acid into the reaction kettle, raise the temperature to 80°C, blow in nitrogen, and esterify at 150°C for 3~5h, then at 170°C, -0.01~-0.096MPa Reaction under reduced pressure for 3~6 hours, the esterification rate is above 99%, and when no fraction is produced, stop the reaction, lower the temperature to 100°C, and discharge the material to obtain a flame-retardant esterification liquid.

[0073] Based on the mass of the flame retardant esterification solution, take 2.0Kg of the flame retardant esterification solution, 0.36Kg of propylenediamine and 1.32kg of ethanol into the reaction kettle, raise the temperature to 60°C, blow in nitrogen, and react at 100°C for 3~5h , and then react under reduced pressure at -0.01~-0.096MPa for 3~6h, when the solid content reaches 85%, stop the reaction to obtain an intumescent flame retardant.

[0074] Based on the mass of the intumescent flame retardant...

PUM

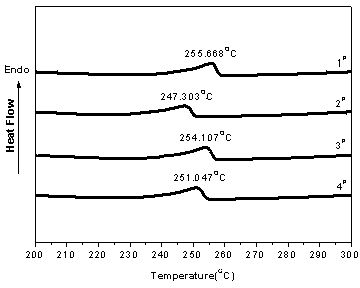

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com