High-adhesive water-based polyurethane anti-corrosion and waterproof coating and preparation method thereof

A water-based polyurethane, high-adhesion technology, applied in the field of coatings, can solve the problems of limited application range, water resistance, solvent resistance and mechanical properties are not ideal, and achieve improved mechanical properties, strong anti-corrosion and waterproof ability, and weather resistance. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

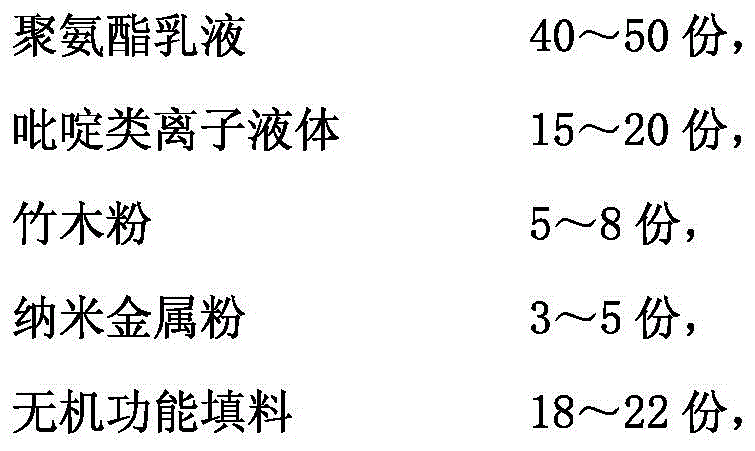

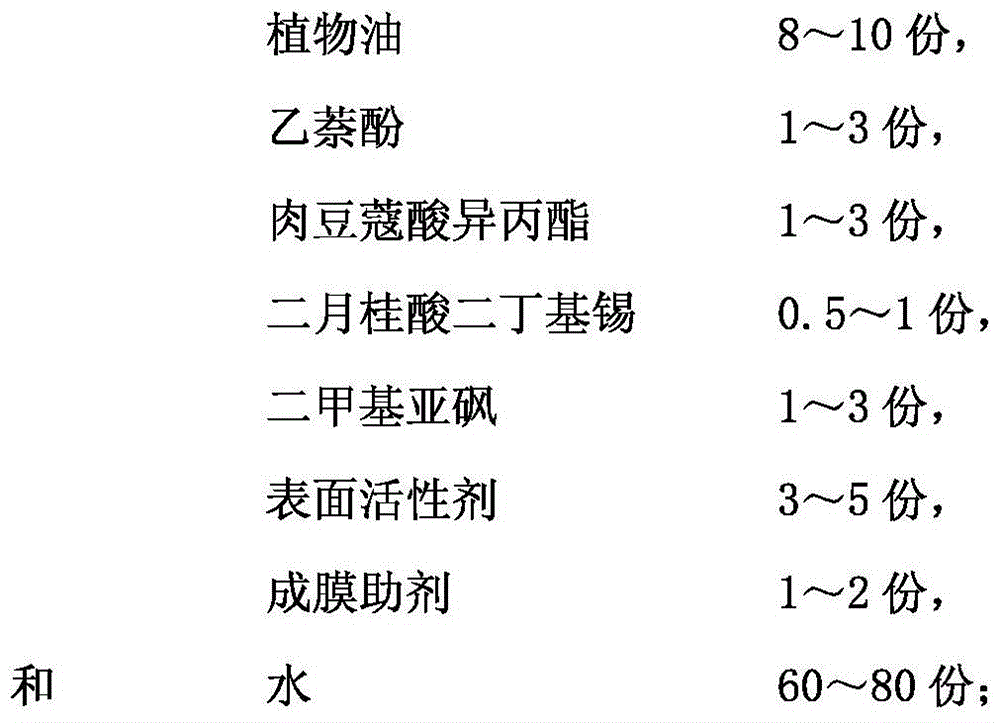

Method used

Image

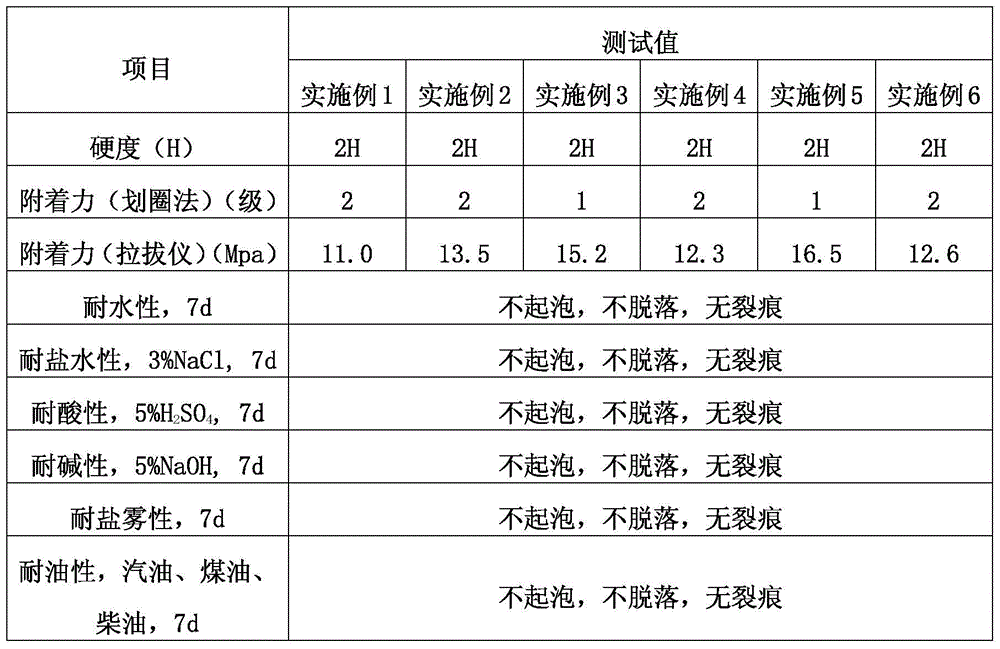

Examples

Embodiment 1

[0021] The concrete preparation steps of coating in the present embodiment are:

[0022] 1) Weigh 14g bamboo wood powder (crystallinity 52%, filter with 100 mesh screen before weighing), bake it in vacuum -0.1Mpa, high temperature 50~55℃ for 1h, take it out, and then mix it with 8g nano Metal powder (wherein containing 3.2g silver powder, 2.6g chromium powder and 2.2g zinc powder) is put into ball mill, ball mills 20min, then the mixture of the two is transferred to mixing mixer, then add 34gN- dodecylpyridine hexafluorophosphate and 8g of cetyltrimethylammonium bromide, stirred at 1200rpm for 0.5h, taken out, and ultrasonically dispersed for 20min;

[0023] 2) Put the dispersion obtained in step 1) in a reaction kettle, heat to 70-75°C, keep at this temperature for 10 minutes, then slowly add 90g of polyurethane emulsion (solid content 30%), stir and react at 1800rpm for 1h, slowly drop Add 1.6g of dibutyltin dilaurate, keep the temperature at 70-75°C for reflux reaction for...

Embodiment 2

[0026] The concrete preparation steps of coating in the present embodiment are:

[0027] 1) Weigh 10g bamboo wood powder (56% crystallinity, filter with 100 mesh screen before weighing), bake it in vacuum -0.1Mpa, high temperature 50~55℃ for 1h, take it out, and then mix it with 10g nano Metal powder (which contains 4.3g silver powder, 2.2g chromium powder and 3.5g zinc powder) is put into a ball mill, ball milled for 20min, then the mixture of the two is transferred to a mixing mixer, and then 40gN-butylpyridinium hexafluorophosphate and 10g2- Sodium undecyl-N-oxyethyl acetate, stirred at 1200rpm for 0.5h, taken out, and ultrasonically dispersed for 20min;

[0028] 2) Put the dispersion obtained in step 1) in a reaction kettle, heat it to 70-75°C, keep it at this temperature for 10 minutes, then slowly add 95g of polyurethane emulsion (solid content 30%), stir and react at 1800rpm for 1h, slowly drop Add 1g of dibutyltin dilaurate, keep the temperature at 70-75°C for reflux ...

Embodiment 3

[0031] The concrete preparation steps of coating in the present embodiment are:

[0032] 1) Weigh 16g bamboo wood powder (55% crystallinity, filter with 100 mesh screen before weighing), bake it in vacuum -0.1Mpa, high temperature 50~55℃ for 1h, take it out, and then mix it with 6g nano Metal powder (which contains 2.2g silver powder, 2.7g chromium powder and 1.1g zinc powder) is put into the ball mill, ball milled for 20min, then the mixture of the two is transferred to the mixing mixer, then add 30gN-butylpyridine tetrafluoroborate and 6g Octylphenyl polyoxyethylene ether, stirred at 1200rpm for 0.5h, taken out, and ultrasonically dispersed for 20min;

[0033] 2) Put the dispersion obtained in step 1) in a reaction kettle, heat to 70-75°C, keep at this temperature for 10 minutes, then slowly add 80g of polyurethane emulsion (solid content 30%), stir and react at 1800rpm for 1h, slowly drop Add 2g of dibutyltin dilaurate, keep the temperature at 70-75°C for reflux reaction f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com