Wood plastic tile extrusion mold

A technology of extruding molds and wood-plastic tiles, which is applied to household appliances, other household appliances, household components, etc., can solve problems such as low strength, low service life, and fragility, and achieve good anti-corrosion and waterproof performance and long service life , the effect of high production efficiency

Inactive Publication Date: 2014-02-12

湖北高新明辉模具有限公司

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

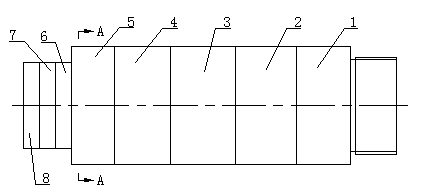

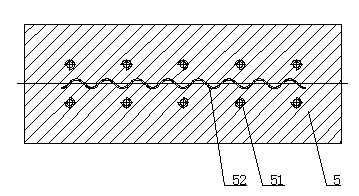

[0008] see Figure 1 to Figure 2 , the present invention includes mold body 1, transition plate two 2, transition plate one 3, manifold 4, die 5, water jacket three 6, water jacket two 7 and water jacket one 8, and the die 5 is provided with multiple A threaded hole 51, and an inner hole 52 is provided in the middle of the die 5, and the cross-sectional shape of the inner hole 52 is a wave groove.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a wood plastic tile extrusion mold. The mold comprises a mold body (1), a second transition plate (2), a first transition plate (3), a cylinder manifold (4), a die (5), a third water jacket (6), a second water jacket (7) and a first water jacket (8), the die (5) is provided with a plurality of screwed holes (51), a bore (52) is arranged in the middle of the die (5), and the cross section of the bore (52) has a waveform-shaped groove shape. The mold has a production efficiency, and wood plastic tiles having the advantages of high strength, good anticorrosive and waterproof performances, environmental protection, beauty and long service life can be produced through the mold.

Description

technical field [0001] The invention relates to a mold, in particular to a wood-plastic tile extrusion mold. Background technique [0002] Existing tiles used in construction include kiln tiles and sulfur glazed tiles, which are low in strength and fragile. Now most of them use asbestos tiles. This kind of tile is not only harmful to the human body, but also has low strength and low service life, and the cost of manufacturing this asbestos tile higher. Contents of the invention [0003] The purpose of the present invention is to provide a wood-plastic tile extrusion die with high production efficiency, high strength, good anti-corrosion and waterproof performance, environmental protection and beauty, and long service life. [0004] In order to achieve the above object, the present invention includes a mold body, transition plate two, transition plate one, manifold, die, water jacket three, water jacket two and water jacket one, the die is provided with a plurality of thre...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B29C47/12B29C48/30

CPCB29C48/30B29L2031/104

Inventor 刘志辉

Owner 湖北高新明辉模具有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com