Special high-performance coating for junction boxes and preparation method of coating

A junction box, high-performance technology, used in anti-corrosion coatings, anti-fouling/underwater coatings, polyurea/polyurethane coatings, etc. Fading and other problems, to achieve the effect of excellent hiding, increased leveling and coating, and long life cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

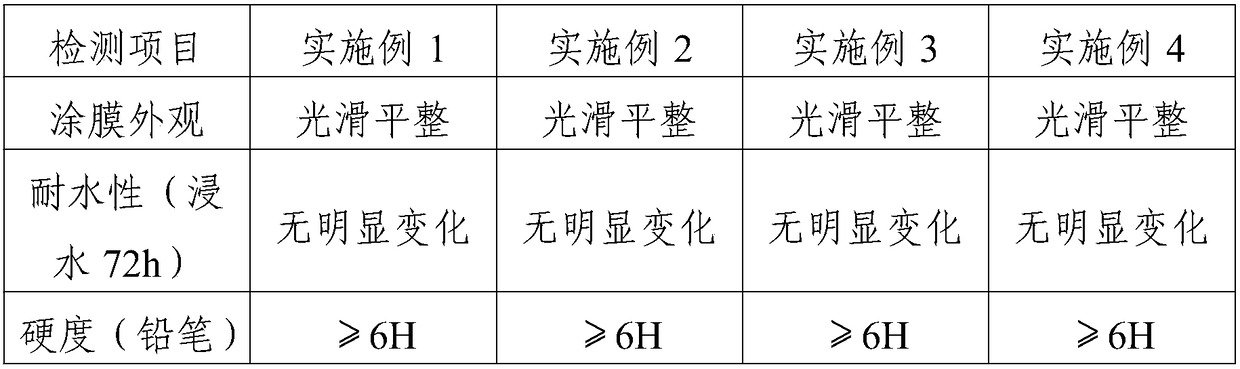

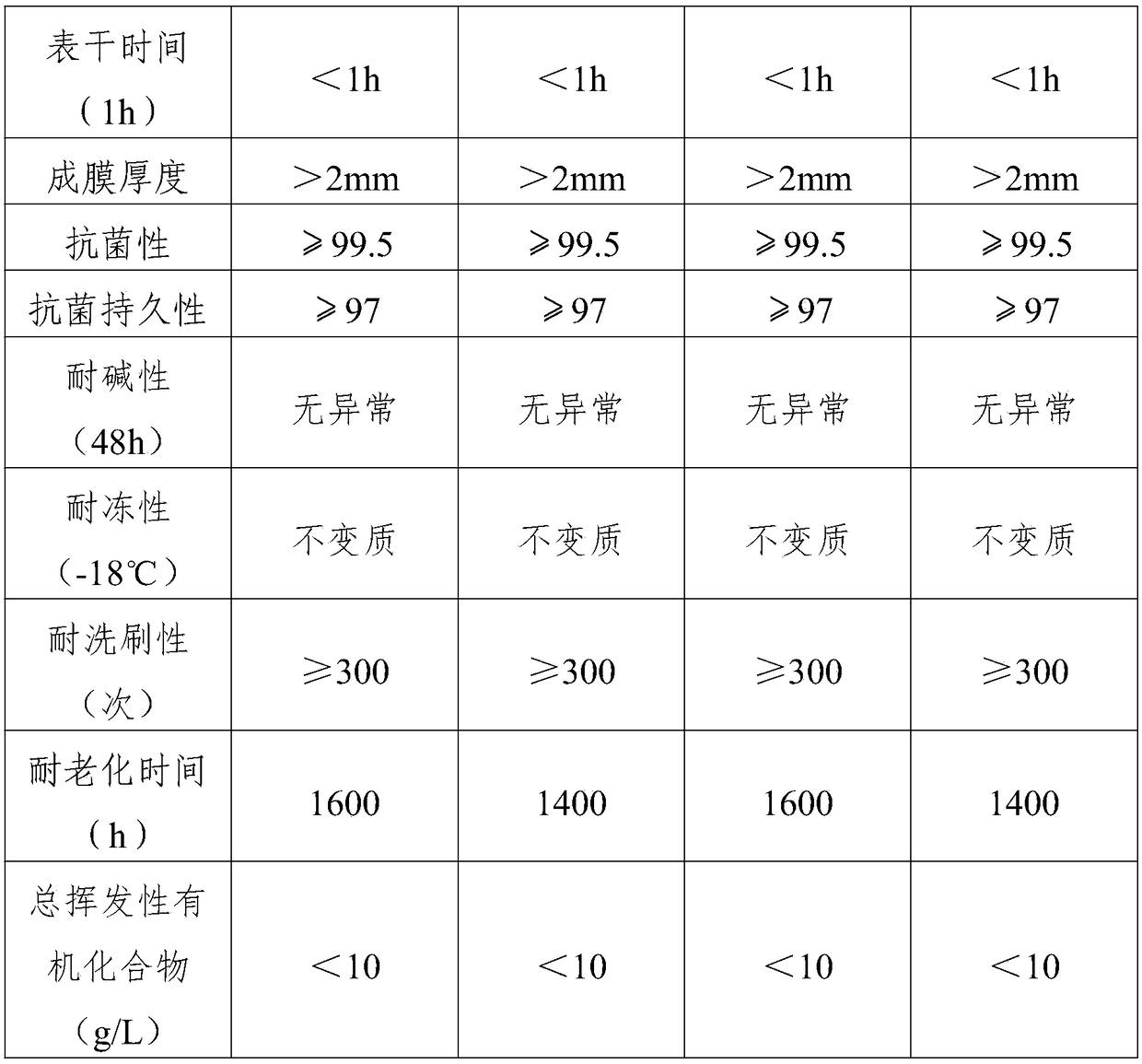

Examples

Embodiment 1

[0022] A special coating for high-performance junction boxes, made of the following raw materials in parts by weight:

[0023] 40 parts of water-based polyurethane emulsion, 30 parts of polyacrylate emulsion, 20 parts of styrene-acrylic emulsion, 12 parts of glass fiber, 5 parts of hollow microspheres, 1 part of alcohol ester twelve, 3 parts of pigment, 6 parts of hexenyl bisstearamide , 0.5 parts of higher fatty alcohol, 20 parts of inorganic filler, 1 part of triethanolamine, 3 parts of industrial salt, 1 part of ethylene glycol, 0.4 part of hexamethylol etherified melamine, 3 parts of emulsified silicone oil, hindered phenolic antioxidant 5 parts, 0.4 parts of non-ionic fluorosurfactant, 0.5 parts of silicone water repellent, 0.7 parts of antiseptic and fungicide, 2 parts of brominated flame retardant.

[0024] Among them, the inorganic filler is made of titanium dioxide, talcum powder, calcium carbonate and barium sulfate mixed in equal mass ratio; the hindered phenolic an...

Embodiment 2

[0026] A special coating for high-performance junction boxes, made of the following raw materials in parts by weight:

[0027] 60 parts of water-based polyurethane emulsion, 20 parts of polyacrylate emulsion, 30 parts of styrene-acrylic emulsion, 6 parts of glass fiber, 8 parts of hollow microspheres, 0.5 parts of alcohol ester twelve, 1 part of pigment, 3 parts of hexenyl bisstearamide , 1 part of higher fatty alcohol, 10 parts of inorganic filler, 2 parts of triethanolamine, 2 parts of industrial salt, 3 parts of ethylene glycol, 0.1 part of hexamethylol etherified melamine, 3 parts of emulsified silicone oil, hindered phenolic antioxidant 3 parts, 0.6 parts of non-ionic fluorine surfactant, 1 part of silicone water repellent, 0.3 parts of antiseptic and fungicide, 4 parts of brominated flame retardant.

[0028] Among them, the inorganic filler is made of titanium dioxide, talcum powder, calcium carbonate and barium sulfate mixed in equal mass ratio; the hindered phenolic an...

Embodiment 3

[0030] A special coating for high-performance junction boxes, made of the following raw materials in parts by weight:

[0031] 50 parts of water-based polyurethane emulsion, 25 parts of polyacrylate emulsion, 25 parts of styrene-acrylic emulsion, 9 parts of glass fiber, 6.5 parts of hollow microspheres, 0.7 parts of alcohol ester twelve, 2 parts of pigment, 4.5 parts of hexenyl bis stearamide , 0.7 parts of higher fatty alcohol, 15 parts of inorganic filler, 1.5 parts of triethanolamine, 2.5 parts of industrial salt, 2 parts of ethylene glycol, 0.3 part of hexamethylol etherified melamine, 4 parts of emulsified silicone oil, hindered phenolic antioxidant 4 parts, 0.5 parts of non-ionic fluorine surfactant, 0.8 parts of silicone water repellent, 0.5 parts of antiseptic and fungicide, 3 parts of brominated flame retardant.

[0032] Among them, the inorganic filler is made of titanium dioxide, talcum powder, calcium carbonate and barium sulfate mixed in equal mass ratio; the hind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com