Heat-insulated protective coating of metal material and preparation method thereof

A metal material, protective coating technology, applied in the direction of coating, device for coating liquid on the surface, pressure inorganic powder coating, etc., can solve the problem of unstable material junction, achieve good heat insulation effect, anti-corrosion and waterproof Good effect and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

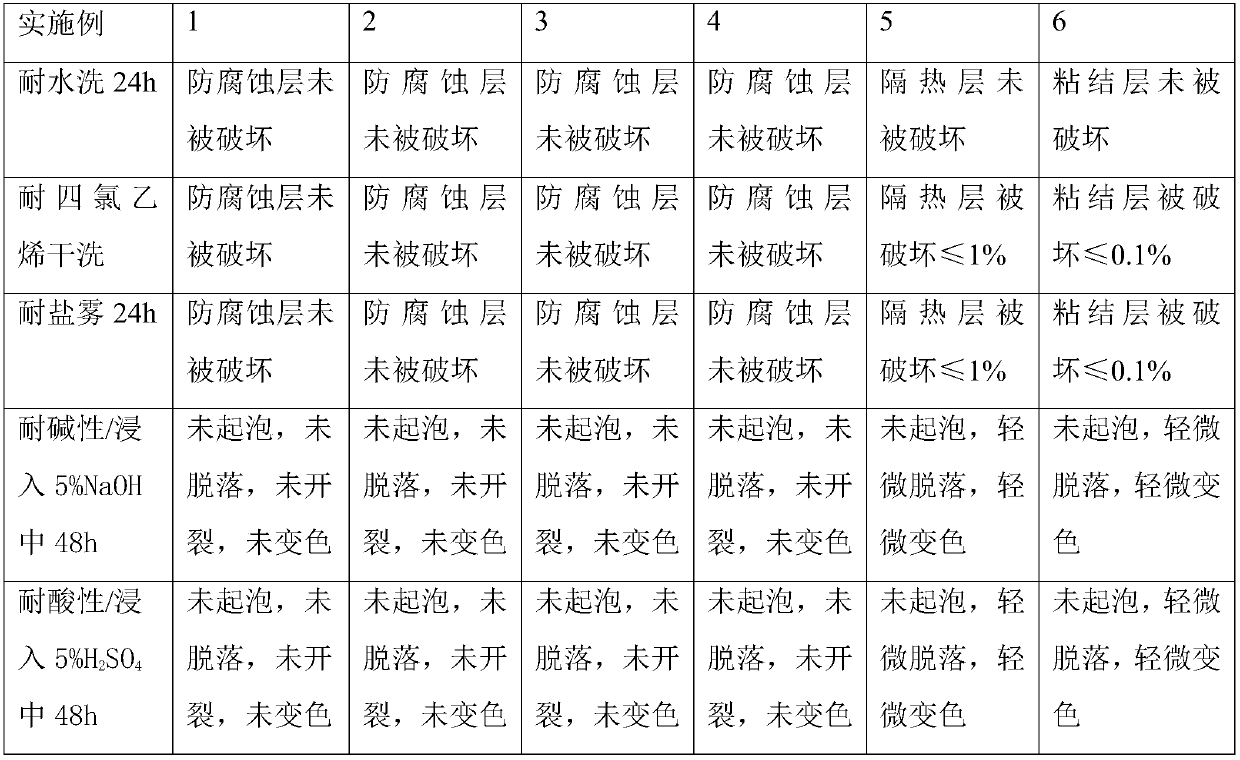

[0040] The technical solution of the present invention will be further described in detail below in conjunction with specific examples, but the protection scope of the present invention is not limited to the following description.

[0041] A heat-insulating protective coating for metal materials, which forms a protective coating on the surface of the metal material by spraying, and the heat-insulating protective coating is composed of the following:

[0042] Adhesive layer, sprayed on the surface of the metal material;

[0043] Thermal insulation layer I, sprayed on the bonding layer surface;

[0044]Heat insulation layer II, sprayed on the surface of heat insulation layer I;

[0045] Anti-corrosion layer, sprayed on the surface of metal materials.

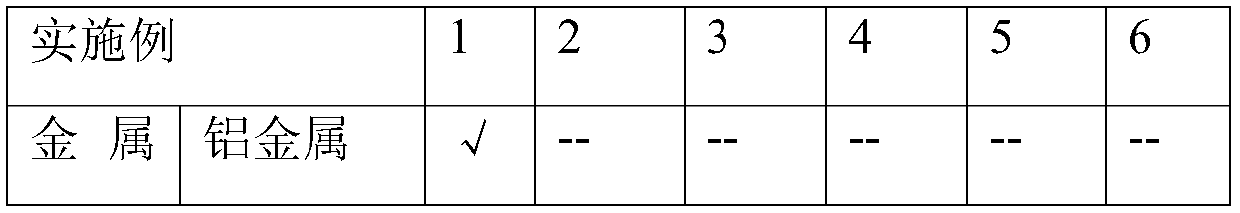

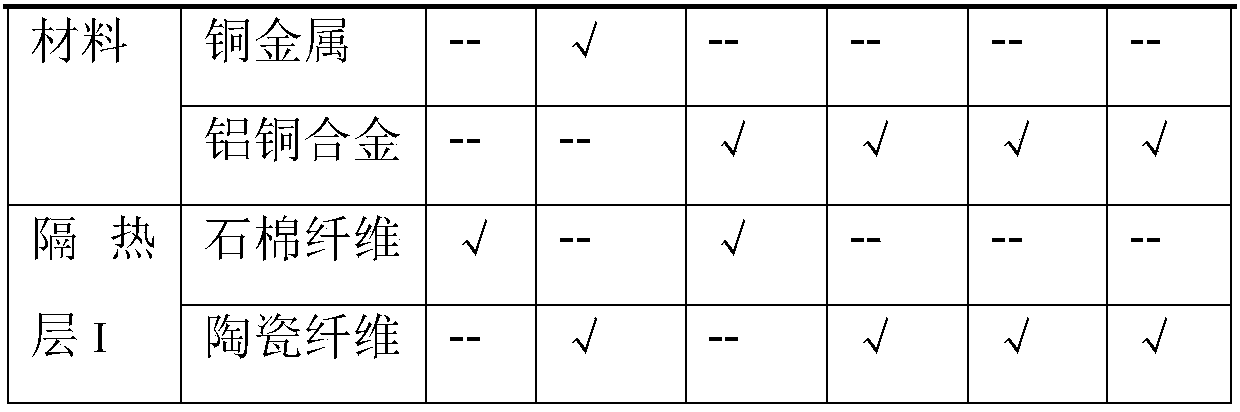

[0046] Specifically, the metal material is aluminum metal, copper metal or aluminum-copper alloy material.

[0047] Specifically, the bonding layer is silicon powder.

[0048] Specifically, the purity of the silicon powder is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thermal stability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com