Heat-insulation film and preparation method thereof

A technology of thermal insulation film and multi-layer thermal insulation, which is applied in heat exchange equipment, chemical instruments and methods, and protection of pipelines through thermal insulation, etc. Small, easy to use, good heat insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings.

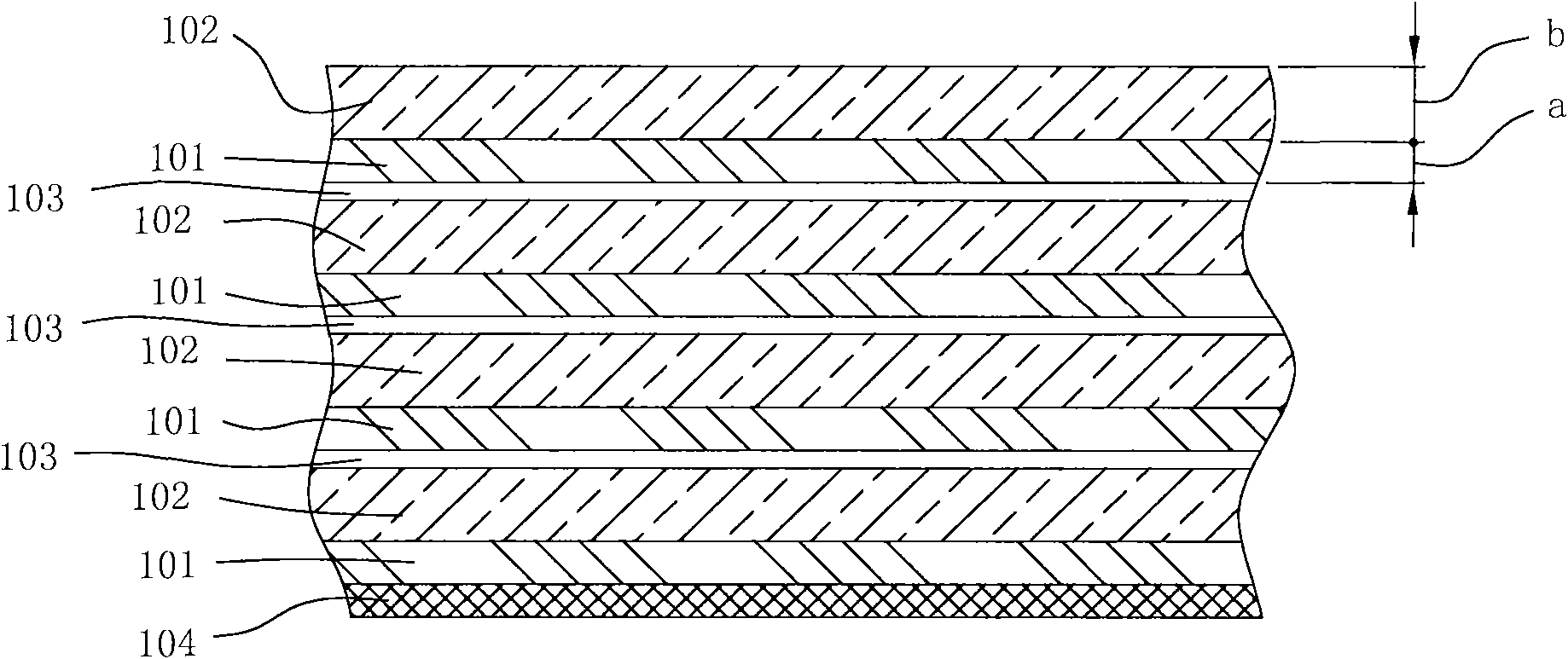

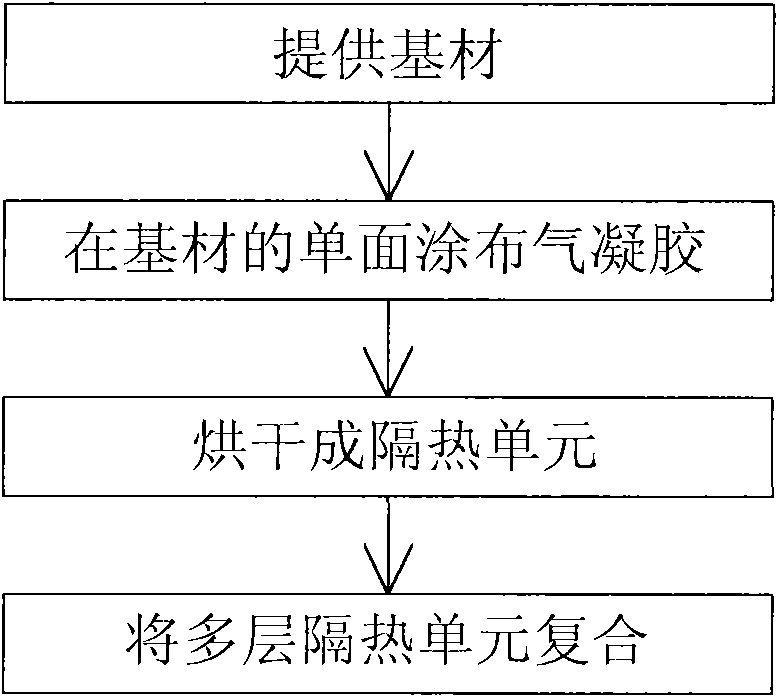

[0035] refer to figure 1 , the first embodiment of the present invention is a heat insulation film, which has a layered structure. The film structure of the heat insulation film is composed of multiple layers of heat insulation units, and the heat insulation units of each layer are arranged in the same direction; Each layer of thermal insulation unit is composed of a base material layer 101 and an airgel layer 102; the base material layer 101 is a polyimide or carbon fiber membrane, and the airgel layer 102 is a porous silica airgel; and, There is also a high temperature adhesive layer 103 between adjacent heat insulation units. The porous silicon dioxide airgel layer is composed of porous silicon dioxide airgel particles, and the porous silicon dioxide airgel particles are nanoscale particles. An aluminized layer 104 is also provided outside the outermost ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com