A method for manufacturing high-strength railway steel mesh

A manufacturing method and technology of steel mesh, applied in the field of metal materials, can solve problems such as corrosion of steel mesh, and achieve the effects of improving adhesion, reducing force displacement, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

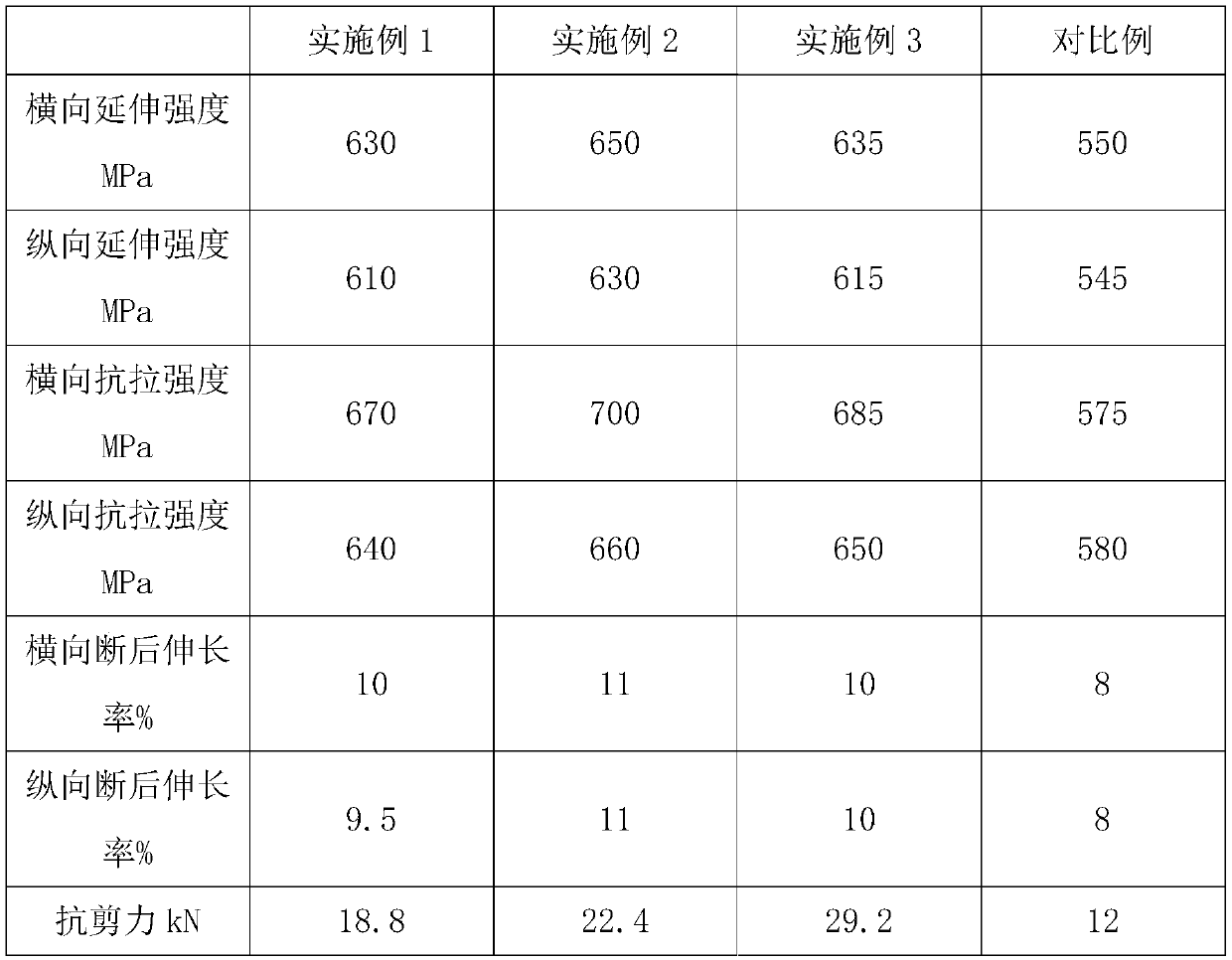

Examples

Embodiment 1

[0024] A method for manufacturing high-strength railway steel mesh, comprising the steps of:

[0025] Step 1, use the steel bar straightening machine to straighten the steel bars, and then cut them into segments according to the size;

[0026] Step 2, add the segmented steel bars into the dilute hydrochloric acid solution and shake for 2 hours, take them out and dry them in the air;

[0027] Step 3, straightening the dried steel bar for the second time, coating the surface of the steel bar with ethyl cellulose alcohol solution, and drying to obtain the coated steel bar;

[0028] Step 4, straighten the coated steel bars and cut them into steel bars, arrange the steel bars to form a mesh structure, and mark the connection points of the steel bars;

[0029] Step 5, using ethanol to remove the ethyl cellulose on the surface of the steel bar at the connection point, and then grinding the connection point into grooves;

[0030] Step 6, coating the neoprene adhesive in the groove, ...

Embodiment 2

[0038] A method for manufacturing high-strength railway steel mesh, comprising the steps of:

[0039] Step 1, use the steel bar straightening machine to straighten the steel bars, and then cut them into segments according to the size;

[0040] Step 2, add the segmented steel bars into the dilute hydrochloric acid solution and shake for 4 hours, take them out and dry them in the air;

[0041] Step 3, straightening the dried steel bar for the second time, coating the surface of the steel bar with ethyl cellulose alcohol solution, and drying to obtain the coated steel bar;

[0042] Step 4, straighten the coated steel bars and cut them into steel bars, arrange the steel bars to form a mesh structure, and mark the connection points of the steel bars;

[0043] Step 5, using ethanol to remove the ethyl cellulose on the surface of the steel bar at the connection point, and then grinding the connection point into grooves;

[0044] Step 6, coating the neoprene adhesive in the groove, ...

Embodiment 3

[0052] A method for manufacturing high-strength railway steel mesh, comprising the steps of:

[0053] Step 1, use the steel bar straightening machine to straighten the steel bars, and then cut them into segments according to the size;

[0054] Step 2, add the segmented steel bars into dilute hydrochloric acid solution and shake for 3 hours, take them out and dry them in the air;

[0055] Step 3, straightening the dried steel bar for the second time, coating the surface of the steel bar with ethyl cellulose alcohol solution, and drying to obtain the coated steel bar;

[0056] Step 4, straighten the coated steel bars and cut them into steel bars, arrange the steel bars to form a mesh structure, and mark the connection points of the steel bars;

[0057] Step 5, using ethanol to remove the ethyl cellulose on the surface of the steel bar at the connection point, and then grinding the connection point into grooves;

[0058] Step 6, coating the neoprene adhesive in the groove, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com