Battery protection plate, adhesive pouring die and battery

A battery protection board and glue filling technology, which is applied in the direction of secondary battery repair/maintenance, battery, secondary battery, etc., can solve the problem that the heat dissipation effect of the mobile phone battery protection board cannot meet the needs of ultra-fast charging batteries, etc., and improve battery life. time, improve battery life and use safety, and reduce the effect of using area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

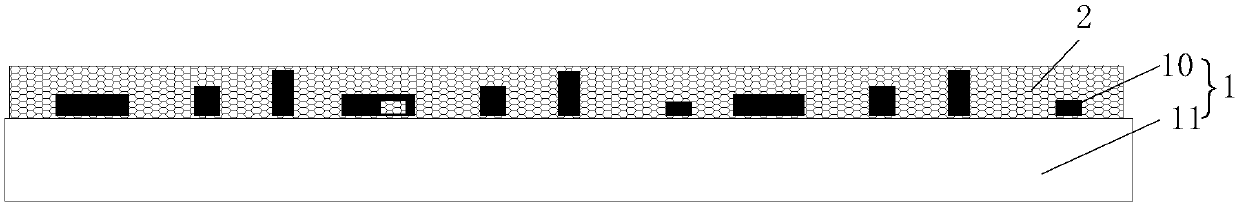

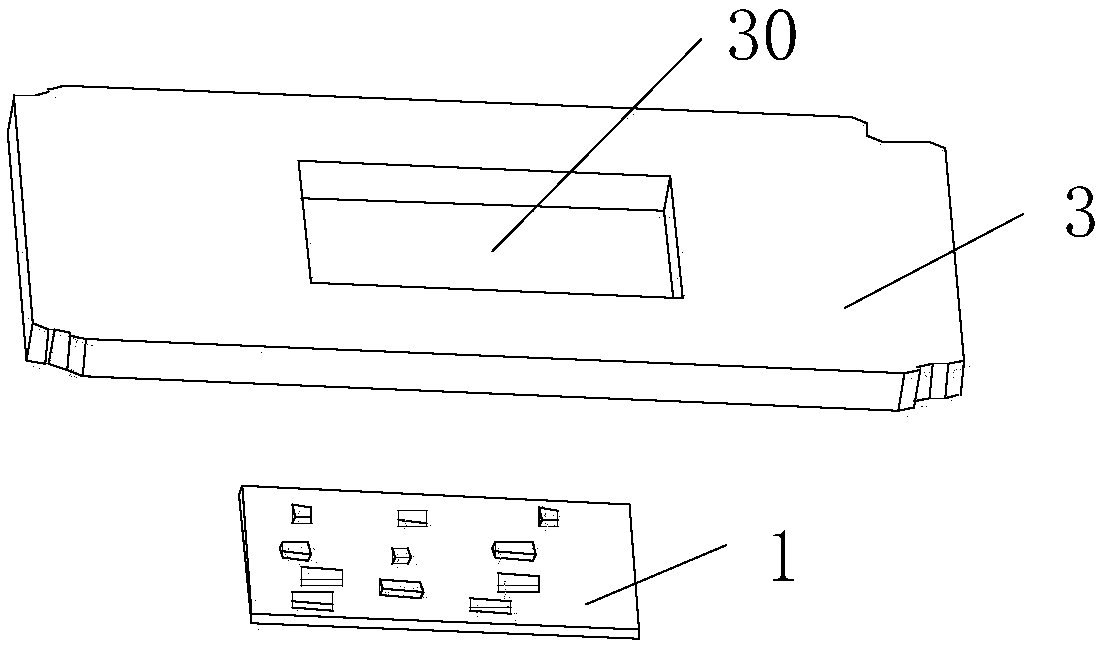

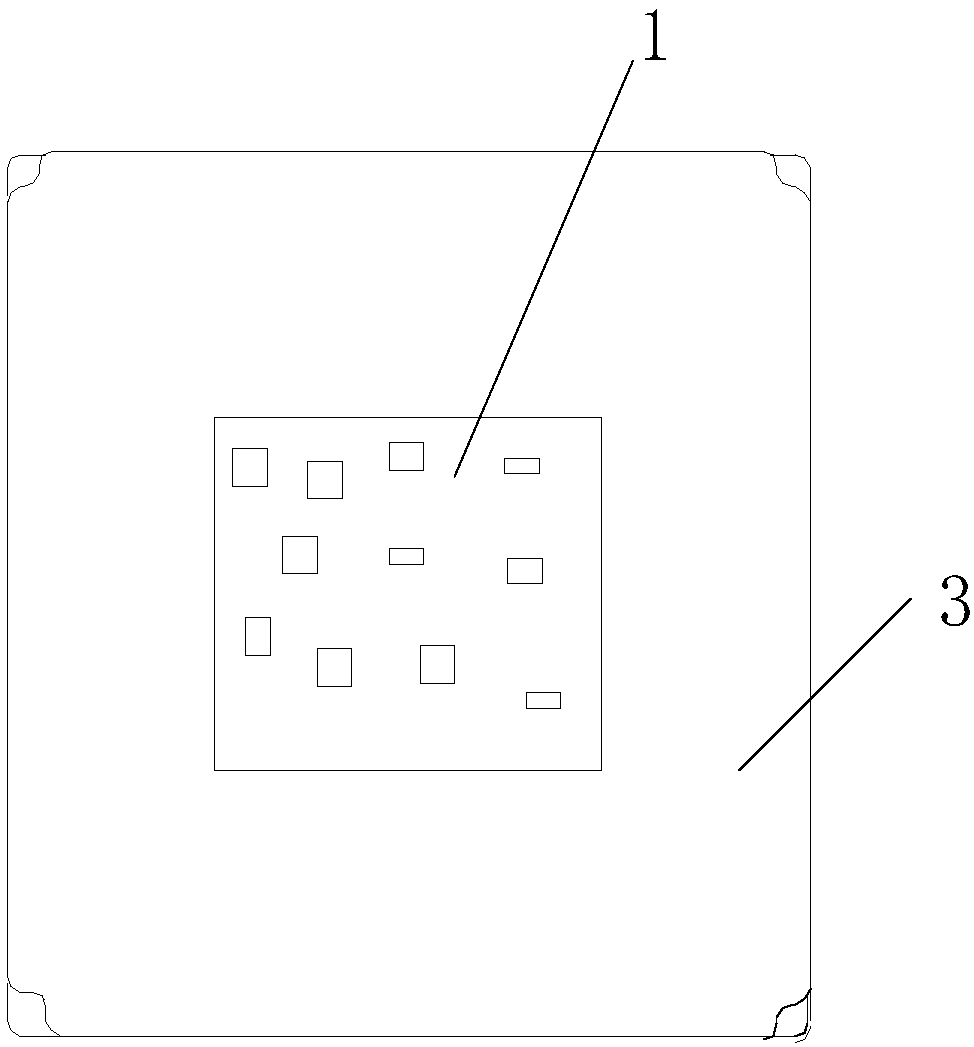

[0023] refer to figure 1 , the embodiment of the present invention proposes a battery protection board, including: a battery protection board body 1 and an adhesive layer 2;

[0024] The battery protection board body 1 includes an electronic component 10 and a substrate 11, and the electronic component 10 is pasted on the substrate 11;

[0025] The glue filling layer 2 covers the electronic component 10 , and the glue filling layer 2 is heat dissipation glue to conduct the heat generated by the electronic component 10 outward.

[0026] In the embodiment of the present invention, the heat dissipation glue that is easy to solidify and form is poured into the battery protection board body 1 to form the glue layer 2 to cover the chip electronic components 10, so as to efficiently dissipate the heat generated by the elect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com