Anticorrosive and waterproof polymer coating for concrete structure

A technology for concrete structures and waterproof coatings, applied in the direction of anti-corrosion coatings, coatings, etc., can solve the problems of inability to form a protective film with concrete, inconvenient use, and failure to achieve anti-corrosion and waterproofing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

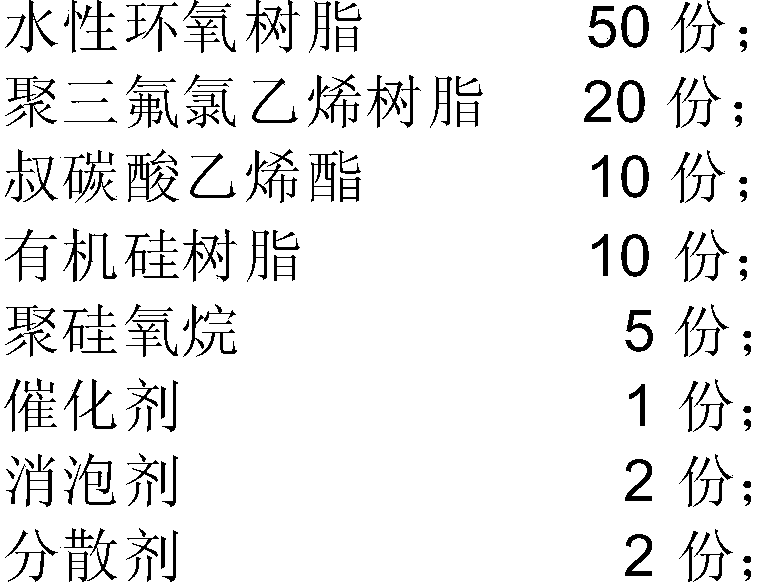

[0012] Group A liquid material

[0013]

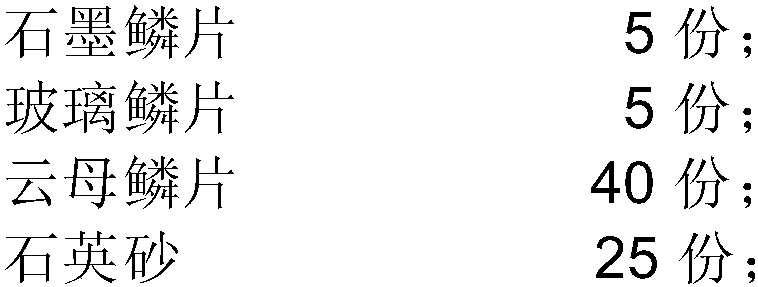

[0014] Group B powder

[0015]

[0016] Polymer anti-corrosion and waterproof coatings form a first-grade material with a composition ratio of liquid material and powder material of 2:1: drying time (25°C): surface dry ≤ 2h, solid dry ≤ 6h;

[0017] Solid content: ≥70%;

[0018] Bond strength: ≥1.8MPa;

[0019] Tensile strength: ≥2MPa;

[0020] Elongation at break: ≥300%;

[0021] Impermeability: impermeable

[0022] Sulfuric acid, hydrochloric acid: ≤20% no foaming, no shedding;

[0023] Nitric acid: ≤15% does not foam or fall off;

[0024] Sodium chloride: ≤15%, no foaming, no shedding;

Embodiment approach 2

[0028] Group A liquid material

[0029]

[0030] Group B powder

[0031]

[0032] Polymer anti-corrosion and waterproof coatings form a secondary material with a composition ratio of liquid material and powder material of 1.5:1:

[0033] Drying time (25°C): surface dry ≤ 2h, hard dry ≤ 8h;

[0034] Solid content: ≥70%;

[0035] Bond strength: ≥1.5MPa;

[0036] Tensile strength: ≥1.6MPa;

[0037] Elongation at break: ≥200%;

[0038] Impermeability: impermeable

[0039] Sulfuric acid, hydrochloric acid: ≤10% no foaming, no shedding;

[0040] Nitric acid: ≤10% does not foam or fall off;

[0041] Sodium chloride: ≤10%, no foaming, no shedding;

[0042] Sodium hydroxide: ≤10% does not foam or fall off;

Embodiment approach 3

[0045] Group A liquid material

[0046]

[0047]

[0048] Group B powder

[0049]

[0050] Polymer anti-corrosion and waterproof coating is composed of liquid material and powder material with a composition ratio of 1:1 to form a tertiary material: drying time (25°C): surface dry ≤ 2h, solid dry ≤ 10h;

[0051] Solid content: ≥70%;

[0052] Bond strength: ≥1.2MPa;

[0053] Tensile strength: ≥1.4MPa;

[0054] Elongation at break: ≥100%;

[0055] Impermeability: impermeable

[0056] Sulfuric acid, hydrochloric acid: ≤5% no foaming, no shedding;

[0057] Nitric acid: ≤5% does not foam or fall off;

[0058] Sodium chloride: ≤5%, no foaming, no shedding;

[0059] Sodium hydroxide: ≤5% no foaming, no shedding;

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bond strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Bond strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com