Preparation method for high-build epoxy coating and prepared coating

A technology of epoxy thick paste and coating, applied in the field of coatings, can solve the problems of hollow coils, difficult operation, sliding of coating facades, etc., and achieve the effects of high elongation, long life and easy construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] (1) Add 15% asphalt, 5% chloroprene rubber, and 13% epoxy resin into distilled water by weight, put them on an electric mixer and stir evenly at a low speed, and mix 20% titanium dioxide and 25% functional fillers according to the density. Add slowly in large order, and at the same time add appropriate amount of defoamer according to the situation, then slowly add film-forming aids and part of thickener, stir evenly at low speed, then move to high-speed stirring disperser, add the remaining part of thickener, and disperse at high speed About 30 minutes to get epoxy thick paste;

[0016] (2) Take 15% of coal tar pitch, 3% of auxiliary materials, and 4% of coal tar in parts by mass, slowly add to the prepared epoxy thick paste, stir at low speed for 30-45min, adjust the viscosity and pH, and discharge to prepare the coating.

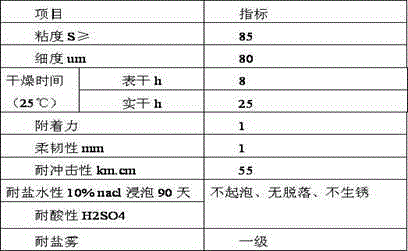

[0017] Perform a performance limit test on it, and the results are as follows:

[0018] The prepared coating property data of table 1 embodiment 1...

Embodiment 2

[0021] (1) Add 20% asphalt, 8% chloroprene rubber, and 12% epoxy resin into distilled water by weight, put them on an electric mixer and stir evenly at a low speed, and mix 15% titanium dioxide and 20% functional fillers according to the density. Add slowly in large order, and at the same time add appropriate amount of defoamer according to the situation, then slowly add film-forming aids and part of thickener, stir evenly at low speed, then move to high-speed stirring disperser, add the remaining part of thickener, and disperse at high speed About 30 minutes to get epoxy thick paste;

[0022] (2) Slowly add 15% of coal tar pitch, 4% of auxiliary materials, and 6% of coal tar into the prepared epoxy thick paste in parts by mass, stir at a low speed for 40-55min, adjust the viscosity and pH, and discharge to prepare the coating;

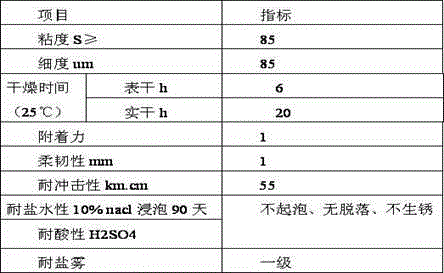

[0023] Perform a performance limit test on it, and the results are as follows:

[0024] The prepared coating property data of table 2 embodiment 2 ...

Embodiment 3

[0027] (1) Add 25% asphalt, 8% chloroprene rubber, and 12% epoxy resin into distilled water by weight, put them on an electric mixer and stir evenly at a low speed, and mix 20% titanium dioxide and 20% functional fillers according to the density. Add slowly in large order, at the same time add appropriate amount of auxiliary materials according to the situation, then slowly add film-forming aids and part of the thickener, stir evenly at a low speed, then move to a high-speed stirring disperser, add the remaining part of the thickener, and disperse at a high speed for about 40 minutes , to get epoxy thick paste;

[0028] (2) Take 10% of coal tar pitch, 3% of auxiliary materials, and 2% of coal tar in parts by mass and slowly add them to the prepared epoxy thick paste, stir at low speed for 30-55min, and use ultrasonic dispersion for about 20min to adjust the viscosity and pH. materials to make coatings;

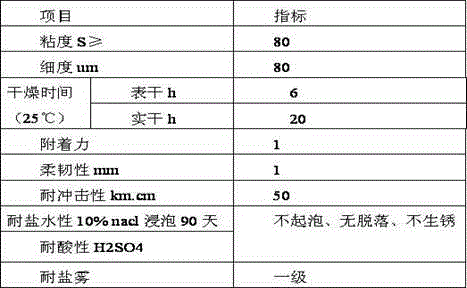

[0029] Perform a performance limit test on it, and the results are as fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com