Rubbing strip with paint-sprayed surface

A technology of anti-scratch strip and topcoat layer, which is applied in transportation, packaging, and vehicle parts, etc. It can solve the problems of poor weather resistance, weak impact resistance, poor corrosion resistance and water resistance, etc., and achieve good gloss and color retention, good Anti-corrosion and waterproof performance, effects of improving weather resistance and impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

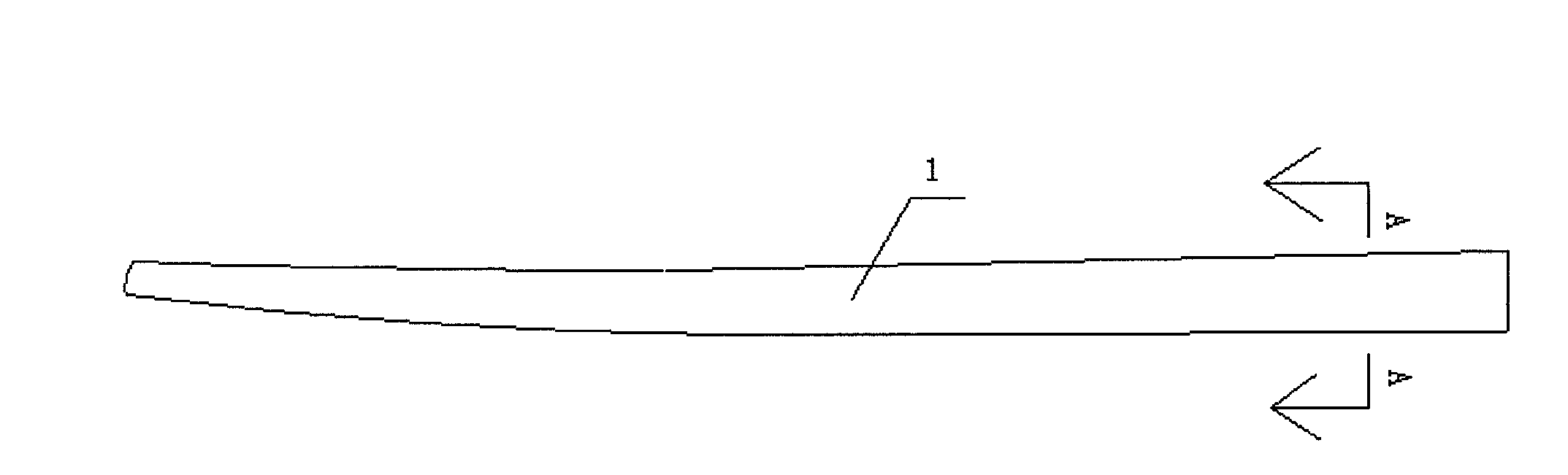

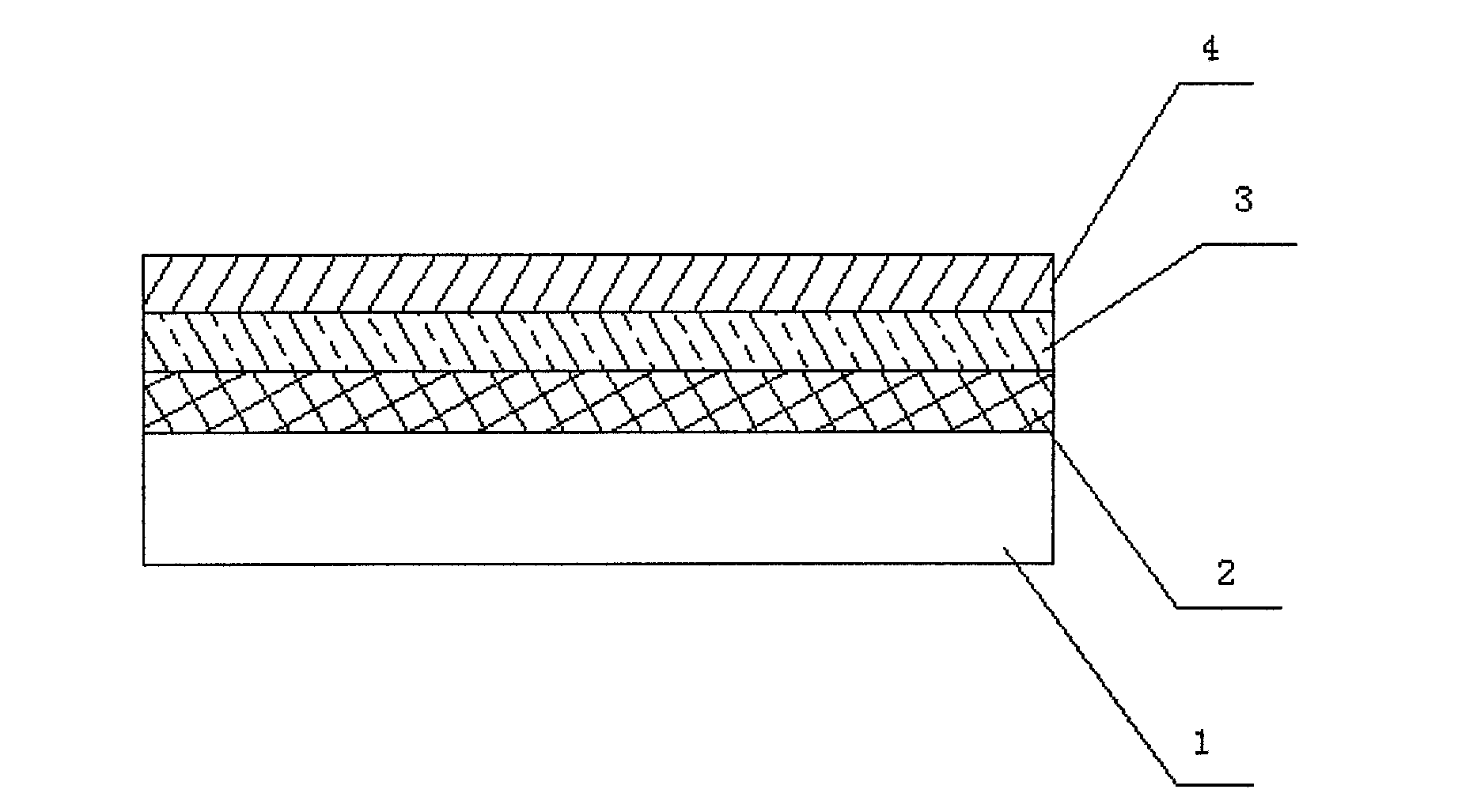

[0011] Such as figure 1 and figure 2 , the invention relates to an anti-scratch strip painted on the surface, the material of the anti-scratch strip is modified polyvinyl chloride, which has strong plasticity, and the modified polyvinyl chloride contains acrylate copolymer as the reinforcement of polyvinyl chloride. Tough modifier improves the weather resistance and impact resistance of the anti-scratch strip, primer, topcoat and varnish are sprayed on the said anti-scratch strip 1, primer layer 2 is on the said anti-scratch strip 1, said On the primer layer 2 is a topcoat layer 3 , and on the topcoat layer 3 is a varnish layer 4 .

[0012] The primer layer 2 provides better alkali resistance and anti-corrosion properties for the anti-scratch strip 1, and can ensure that the topcoat can be absorbed evenly; Aging and waterproof performance, and make the anti-scratch strip 1 have better gloss and color retention and air permeability; the varnish layer 4 is coated on the top c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com