Energy-saving engineering machinery hydraulic oil and preparation method thereof

A technology of construction machinery and hydraulic oil, applied in the field of hydraulic oil, can solve the problems of difficult to meet the hydraulic system, shorten the life of oil products, poor oxidation stability, etc., and achieve the effects of saving energy consumption, reducing friction, and uniform pressure transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

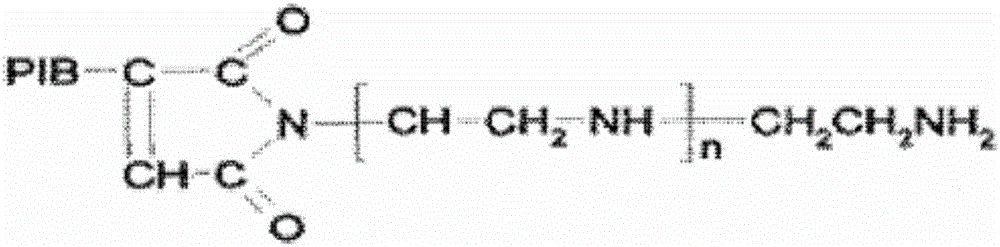

[0035] Energy-saving construction machinery hydraulic oil raw materials (parts by weight): 0.6 parts of tricresyl phosphate, 1.0 parts of antiwear agent, 5 parts of benzotriazole octadecylamine salt, 3 parts of ethylene glycol oleate, hydrogenated styrene isoprene 80 parts of copolymer, 2 parts of monoalkenyl succinimide, 2 parts of 2,5-di-tert-butyl hydroquinone, 3 parts of 4,4'-dioctyl diphenylamine, 6 parts of polymethacrylate parts, 0.03 parts of simethicone oil, and 900 parts of base oil.

[0036] The base oil is obtained by uniformly stirring and mixing dinonyl sebacate, diisopropyl sebacate, and pentaerythritol tetramyristate in a mass ratio of 1:1:1.

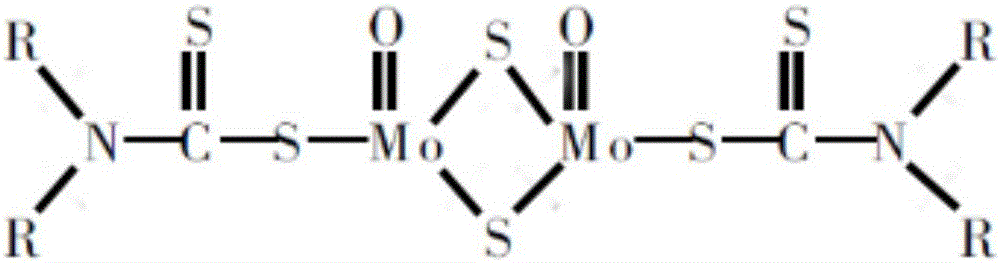

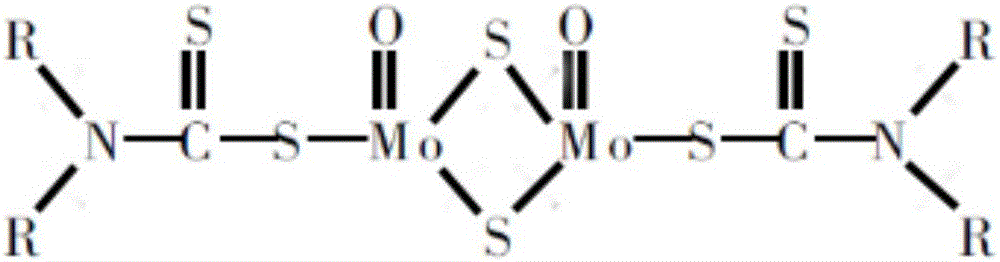

[0037] The anti-wear agent is composed of 50wt% N, N-di(2-ethylhexyl) molybdenum dithiocarbamate and 50wt% N, N-bis(tridecyl) molybdenum dithiocarbamate, and stir and mix uniformly get.

[0038] Preparation of energy-saving engineering machinery hydraulic oil: add base oil to the blending kettle, heat up to 75°C, add p...

Embodiment 2

[0040] It is basically the same as Example 1, except that the base oil is uniformly obtained by stirring and mixing diisopropyl sebacate and pentaerythritol tetramyristate at a mass ratio of 1:1. Obtain the energy-saving engineering machinery hydraulic oil of embodiment 2.

Embodiment 3

[0042] It is basically the same as Example 1, except that the base oil is obtained by stirring and mixing dinonyl sebacate and pentaerythritol tetramyristate at a mass ratio of 1:1. Obtain the energy-saving engineering machinery hydraulic oil of embodiment 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com