Terminated poly(ether-ether-ketone), and preparation method thereof

A technology of polyetheretherketone and p-hydroxyanisole, which is applied in the field of capped polyetheretherketone and its preparation, and can solve problems affecting product quality, PEEK molecular weight and uneven distribution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

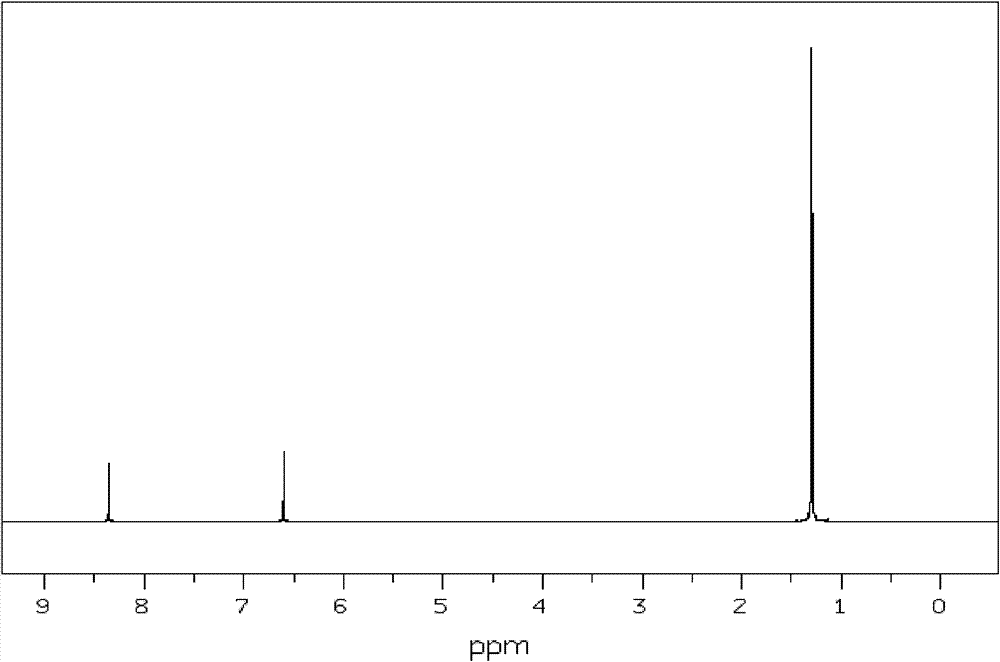

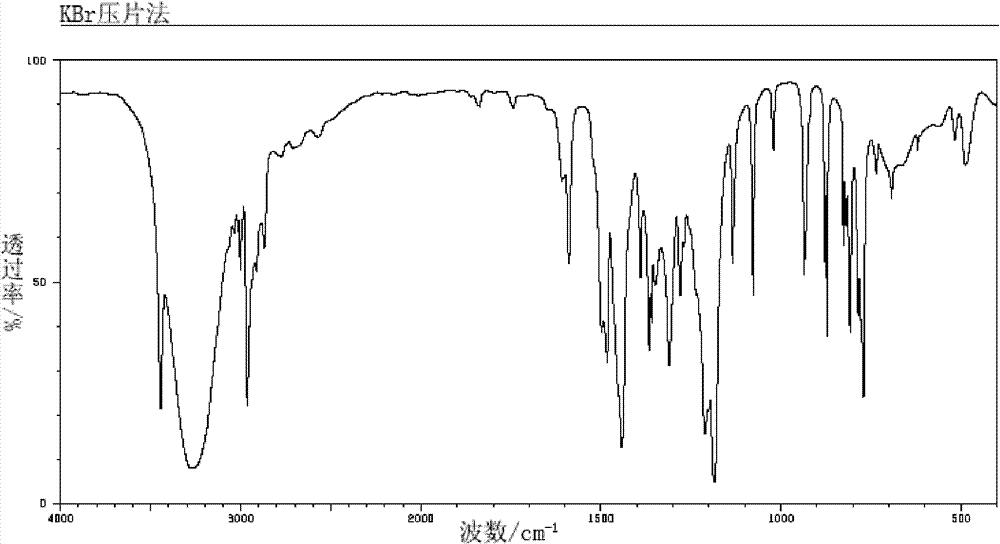

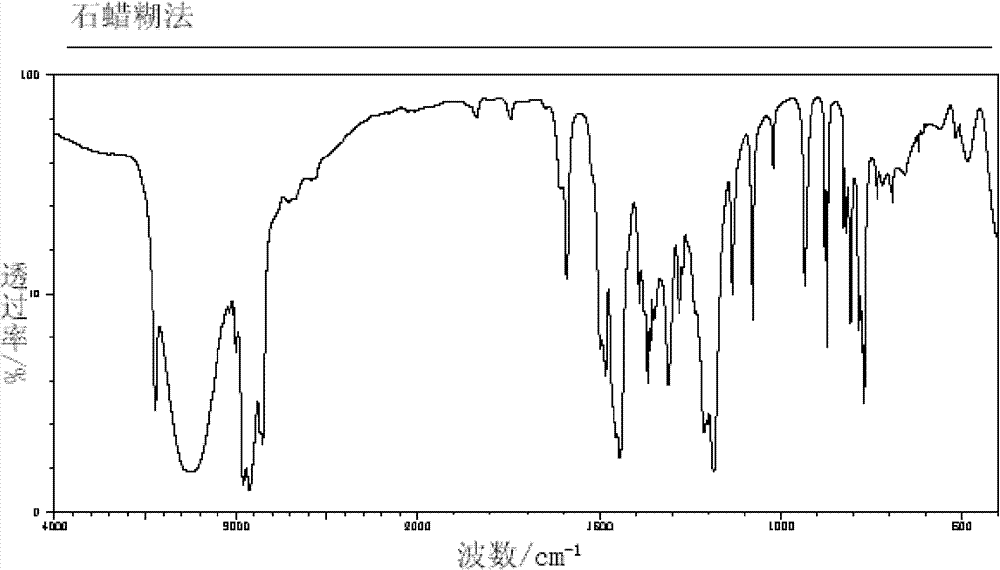

Image

Examples

Embodiment 1

[0062] 65.45g (0.3mol) of 4,4'-difluorobenzophenone, 33.03g (0.3mol) of hydroquinone, 174.58g (0.8mol) of diphenylsulfone, 48.5ml (0.4mol) of xylene, without Add 47.7g (0.45mol) of sodium carbonate water and 4.2g (0.03mol) of anhydrous potassium carbonate into a 1000ml three-neck flask equipped with an electric speed-adjustable stirring device and a condensing reflux device, and continue to feed nitrogen protection. Heat the three-necked bottle, and start stirring after all the materials are melted. The temperature was raised to 145° C., stirred and refluxed for 2 hours. Then remove the condensing reflux device, continue to heat up, and distill out xylene at the same time. When the temperature rises to 180°C, it is maintained for half an hour to completely evaporate the xylene. Then the temperature was raised to 280° C. and reacted for 2 hours. 10 g (0.045 mol) of 2,5-di-tert-butylhydroquinone was added, and the reaction was continued for half an hour. The reaction solutio...

Embodiment 2

[0065] With hydroquinone 33.03g (0.3mol), diphenylsulfone 174.58g (0.8mol), xylene 48.5ml (0.4mol), anhydrous sodium carbonate 47.7g (0.45mol), anhydrous potassium carbonate 4.2g (0.03 mol) into a 1000ml three-neck flask equipped with an electric speed-regulating stirring device and a condensing reflux device, and continuously feed nitrogen protection. Heat the three-necked bottle, and start stirring after all the materials are melted. The temperature was raised to 145° C., stirred and refluxed for 2 hours. Then remove the condensing reflux device, continue to heat up, and distill out xylene at the same time. When the temperature rises to 180°C, it is maintained for half an hour to completely evaporate the xylene. Then 65.45 g (0.3 mol) of 4,4'-difluorobenzophenone was added, the temperature was raised to 280°C, and the reaction was carried out for 2 hours. Then 2.22 g (0.01 mol) of 2,5-di-tert-butylhydroquinone was added, and the reaction was continued for half an hour. T...

Embodiment 3

[0068] 65.45g (0.3mol) of 4,4'-difluorobenzophenone, 74.48g (0.6mol) of p-hydroxyanisole, 174.58g (0.8mol) of diphenylsulfone, 48.5ml (0.4mol) of xylene, Add 47.7g (0.45mol) of anhydrous sodium carbonate and 4.2g (0.03mol) of anhydrous potassium carbonate into a 1000ml three-necked flask equipped with an electric speed-adjustable stirring device and a condensing reflux device, and continue to pass nitrogen protection. Heat the three-necked bottle, and start stirring after all the materials are melted. Raise the temperature to 145°C, stir and reflux for 2 hours, add 4g (0.03mol) of aluminum trichloride and 7.5g (0.03mol) of boron tribromide, and continue to reflux for two hours. Remove the condensing reflux device, and evaporate the xylene while heating up. When the temperature rises to 180°C, it is maintained for half an hour to completely evaporate the xylene. The temperature was raised to 230° C. and reacted for 5 hours. The reaction solution was poured into cold distille...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com