Heat-insulation coating

A thermal insulation and coating technology, applied in the field of thermal insulation coatings, international patent classification C09D coating composition, can solve the problems of not taking into account thermal insulation performance and convenient construction and operation, and achieve easy construction and operation, strong adhesion , the effect of good fire resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

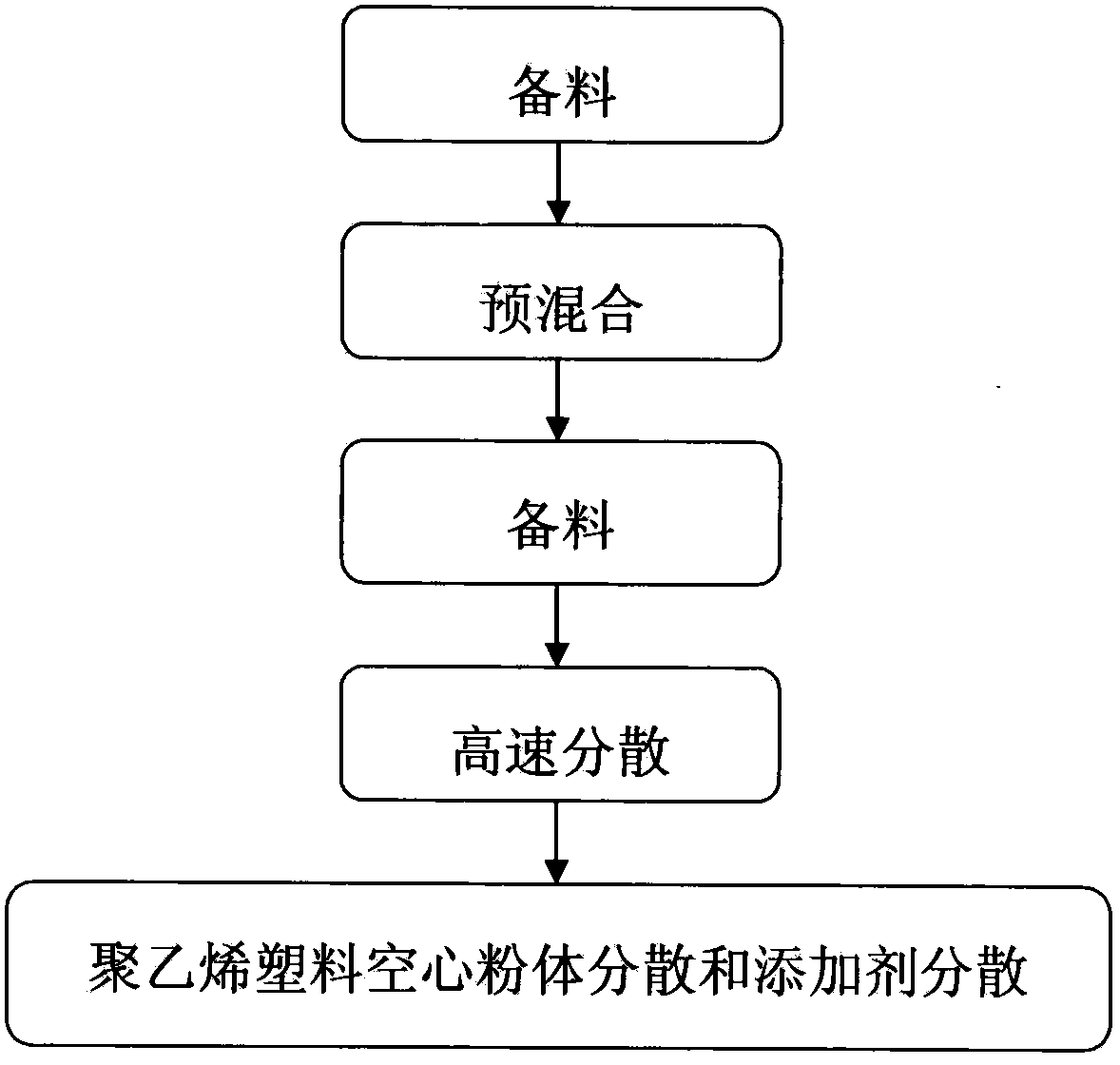

[0010] The present invention will be further described below in conjunction with drawings and embodiments.

[0011] The thermal insulation coating of the present invention is formed by mixing the following raw materials in parts by weight: 20% to 25% of basic epoxy resin, 15% to 20% of a polyethylene plastic hollow powder as the main body, plus 25% ~30% water, 15%~20% viscous agent A and 5%~20% additive B agent; wherein, A agent is composed of 15% methyl methacrylate and 35% ethyl acrylate ester, 40% butyl acrylate, and 10% active agent; agent B is composed of 20% di-tert-butyl hydroquinone antioxidant, 25% acid-resistant additive, 25% alkali-resistant additive, 10% toughness additive, 20% defoamer.

[0012] In the foregoing, the organic hollow powder is a polyethylene plastic polymer sphere.

[0013] The production method of the thermal insulation paint in the present invention includes five steps of material preparation, premixing, high-speed dispersion, hollow organic pow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com