Aluminum alloy section wooden transfer method

An aluminum alloy profile and wood grain transfer printing technology, which is applied in decorative arts, special patterns, and techniques for producing decorative surface effects, etc., can solve the problems of poor performance and quality of the transferred wood grain paint film, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] One, the present invention will be further described below in conjunction with embodiment.

[0026] A wood grain transfer printing method for aluminum alloy profiles:

[0027] First, carry out surface treatment on the aluminum alloy profile; degrease, wash and dry the surface of the aluminum alloy profile, then immerse it in polysiloxane, take it out and dry it, and form a siloxane passivation layer on the surface of the aluminum alloy profile ;

[0028] Then electrostatically spray the transfer primer on the surface of the aluminum alloy profile and cure it;

[0029] Finally, transfer the wood grain on the surface of the transfer primer. Control the transfer temperature at 120-140°C for 35-40 minutes.

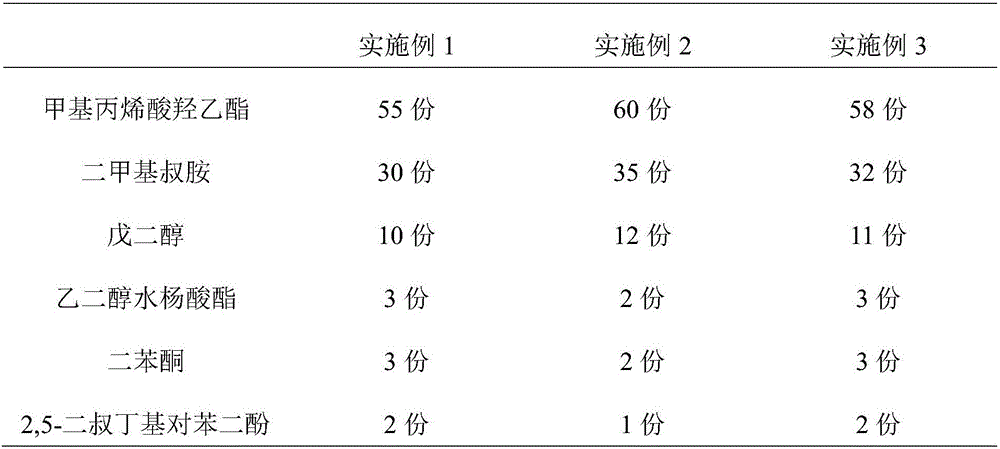

[0030] The transfer primer is made up of raw materials in parts by weight described in Table 1:

[0031] Table 1. Raw material composition of transfer primer

[0032] (unit: parts by weight)

[0033]

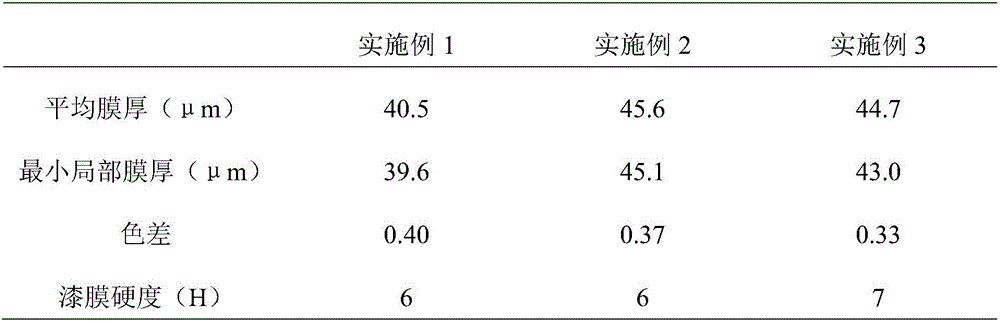

[0034] The preparation method of the transfer primer is as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com