Water-soluble poly(3,4-ethylenedioxythiophene) and preparation method for conductive coating thereof

A technology of ethylenedioxythiophene and water-soluble polymer, which is applied in the direction of conductive coatings and coatings, and can solve the problems of device performance degradation and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

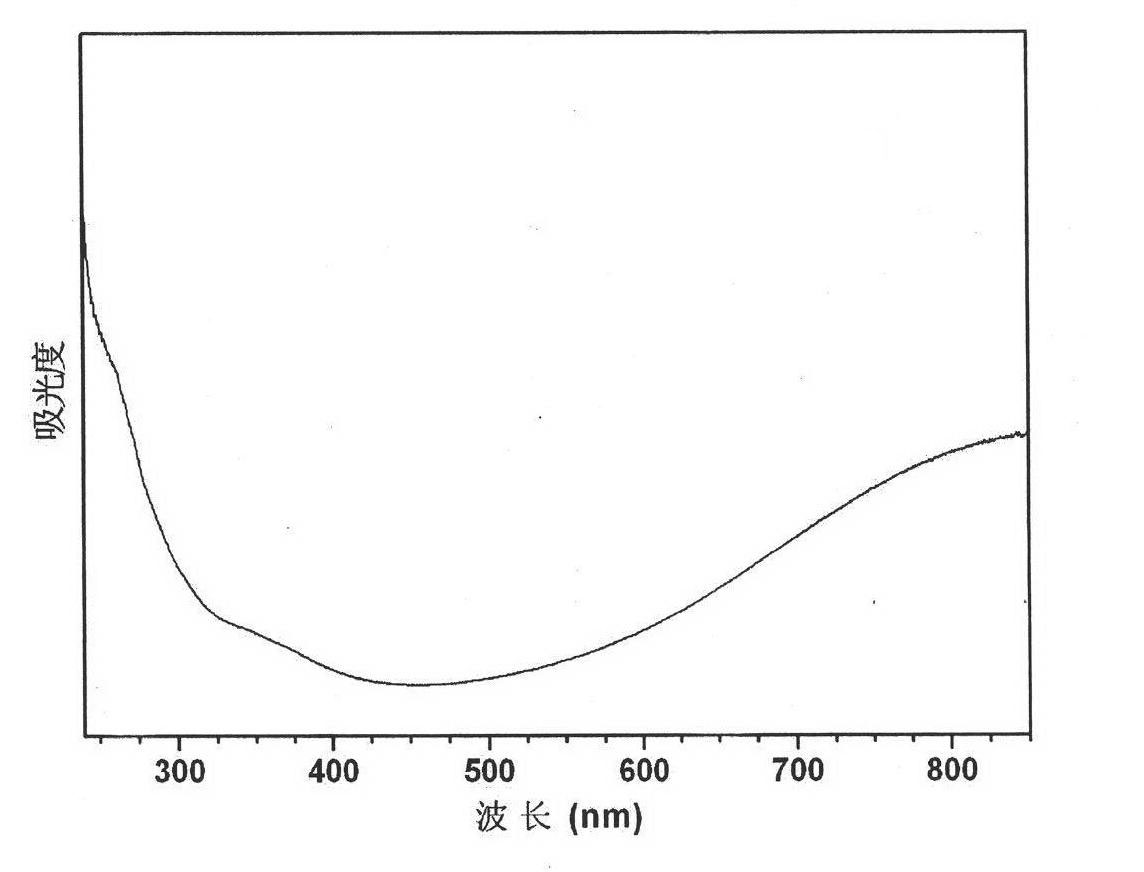

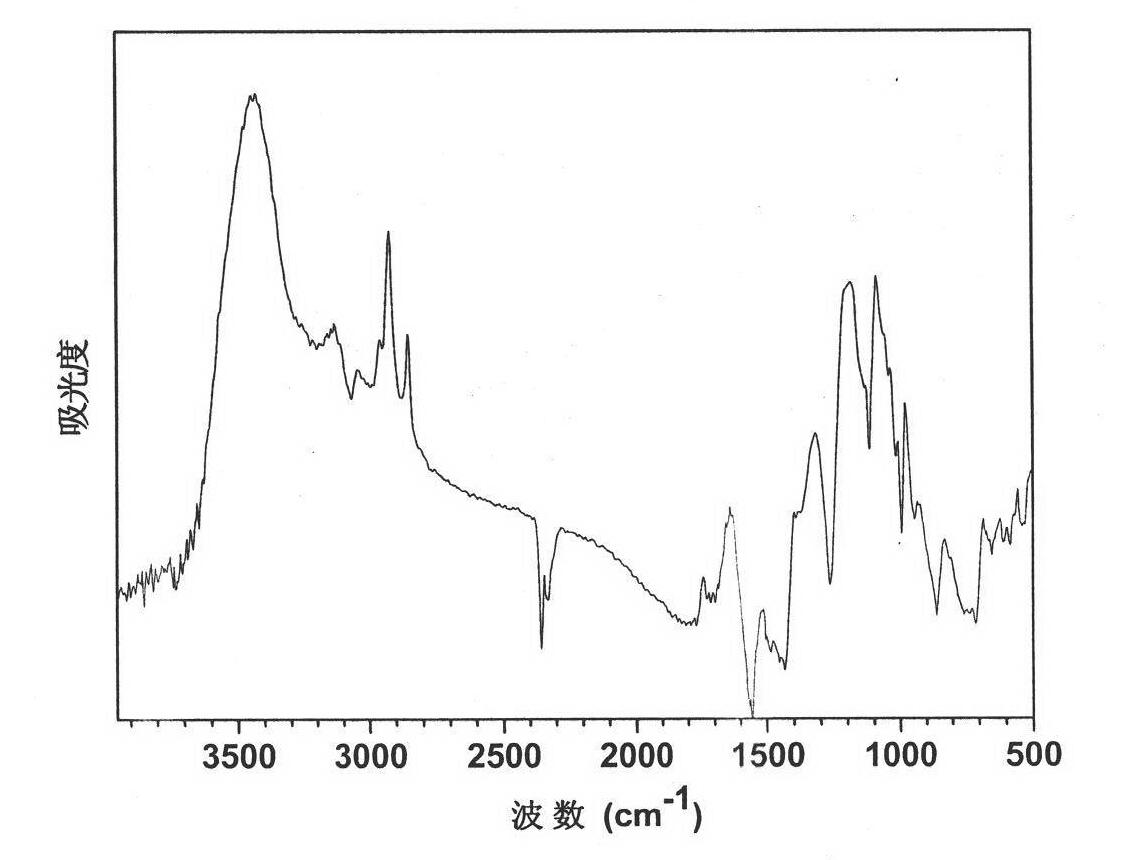

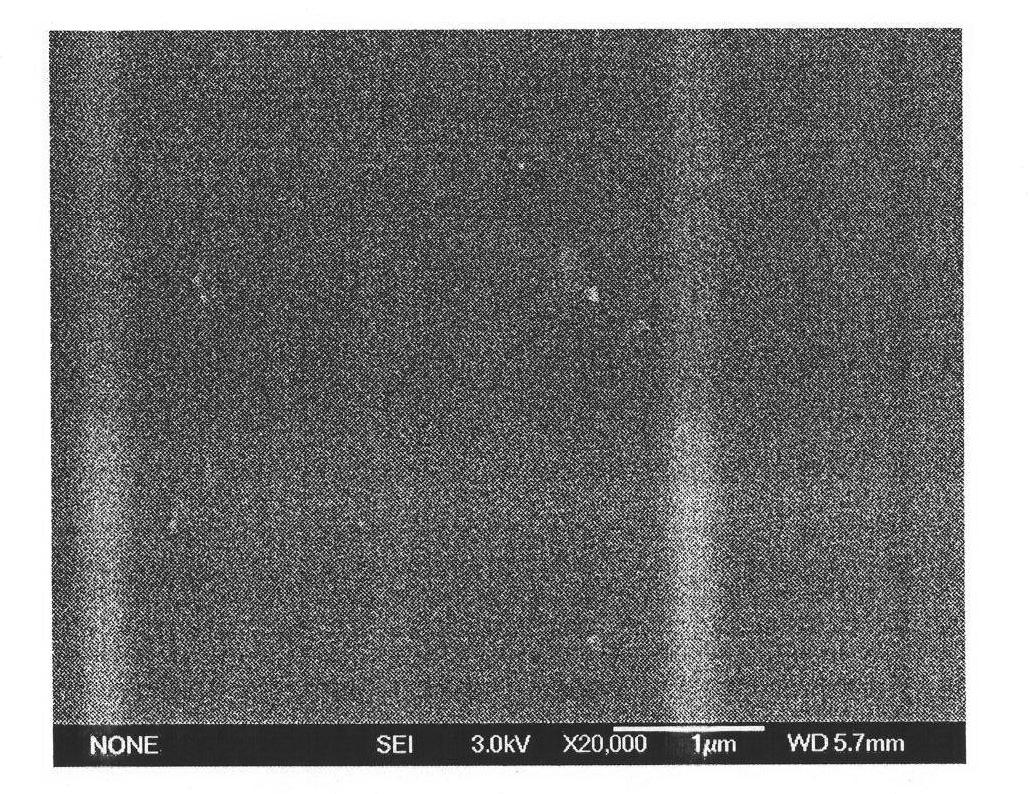

[0025] Example 1. Preparation of water-soluble poly(3,4-ethylenedioxythiophene) / poly(sodium styrene sulfonate-butyl acrylate) [PEDOT / P(SS-BA)] composite

[0026] Firstly, P(SS-BA) copolymer was prepared by traditional solution radical polymerization method. The specific steps are: first add 8g of sodium styrene sulfonate and 2g of butyl acrylate into a 250mL three-necked flask equipped with a condenser and a mechanical stirring paddle, and add 100mL of N,N-dimethylacetamide, and heat the solution to 70°C to completely dissolve sodium styrene sulfonate and butyl acrylate. Weigh 0.1 g of benzoyl peroxide (BPO) and dissolve it in 5 ml of N,N-dimethylacetamide. Use a dropping funnel to drop the initiator solution into the monomer solution and increase the temperature to 85°C. After reacting for 10 hours, the temperature was increased to 90° C. and reacted for 2 hours, and the product was poured out from the three-necked flask. First, the product is evaporated under reduced pressur...

Embodiment 2

[0032] Example 2. Preparation of water-soluble poly(3,4-ethylenedioxythiophene) / poly(sodium styrene sulfonate-methyl acrylate) [PEDOT / P(SS-MA)] composite

[0033] The water-soluble PEDOT / P (SS-MA) composite was prepared according to the steps of Example 1 (variation of the vinyl monomer). The copolymer P (SS-MA) used is 0.29g, the EDOT monomer used is 0.426ml (about 0.568g, the concentration of water is 0.2mol / L), and the oxidant is potassium persulfate 1.62g (0.006mol, The molar ratio to EDOT is 1.5), and react at room temperature for 16 hours.

[0034] The electrical conductivity of the obtained product was 13.7 S / cm.

Embodiment 3

[0035] Example 3. Preparation of water-soluble water-soluble poly(3,4-ethylenedioxythiophene) / poly(sodium styrene sulfonate-octadecyl acrylate) [PEDOT / P(SS-SA)] composite

[0036] The water-soluble PEDOT / P (SS-SA) complex was prepared according to the steps of Example 1 (variation of the vinyl monomer). The copolymer P (SS-SA) used is 0.48g, the EDOT monomer used is 0.043ml (about 0.057g, the concentration of water is 0.02mol / L), and the oxidizing agent is sodium persulfate 0.096g (with EDOT The molar ratio is 1.2), and the reaction is carried out at room temperature for 72 hours.

[0037] The conductivity of the resulting product was 24.2 S / cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com