Emulsion for bi-component wood bonding adhesive and synthesis method thereof

A panel glue, two-component technology, applied in the direction of adhesives, adhesive types, adhesive additives, etc., can solve the problems of polluting the ecological environment and human health, achieve fast drying speed, improve conversion rate, and improve water resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

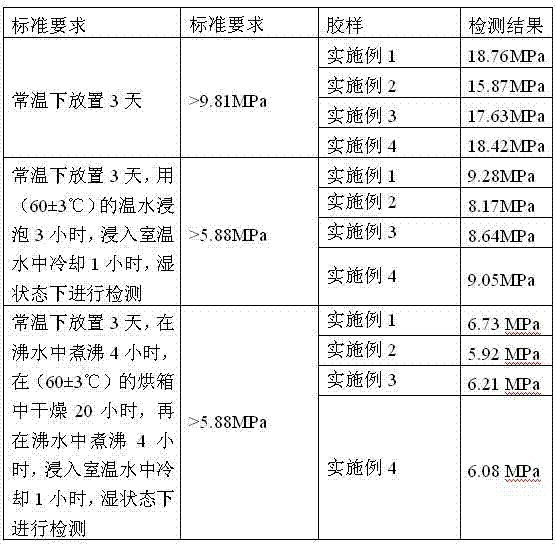

Examples

preparation example Construction

[0062] Embodiments of the present invention further provide a method for preparing the emulsion for puzzle glue, comprising the following steps:

[0063] (1) dissolving the initiator in 20 parts by weight of water to obtain an initiator solution for polymerization;

[0064] (2) 120-130 parts by weight of vinyl acetate, vinyl tertiary carbonate monomer, hydroxyethyl methacrylate, functional monomer, and methacrylic acid are mixed and stirred evenly to make a mixed monomer;

[0065] (3) Add polyvinyl alcohol and 165-185 parts by weight of water in a container, heat to 90-96°C under stirring conditions to dissolve for 50-60 minutes, then cool down to 50-60°C, add emulsifier, buffer, Then add 15 parts by weight of vinyl acetate and 6 parts by weight of initiator solution, and emulsify for 10-15 minutes;

[0066] (4) Raise the temperature to 70-80°C, keep it warm for 25-35 minutes, and start to drop the mixed monomer prepared in step 2 after there is no reflux, and control the dro...

Embodiment 1

[0071] The ammonium persulfate of 0.4 parts by weight is dissolved in 20 parts by weight of water to obtain an initiator solution; 120 parts by weight of vinyl acetate, 8 parts by weight of tertiary carbonic acid vinyl ester monomer VeoVa-9, acetoacetoxymethyl 2.0 parts by weight of ethyl acrylate, 5 parts by weight of hydroxyethyl methacrylate, and 1.5 parts by weight of methacrylic acid were mixed and stirred evenly to prepare a total of 136.5 parts by weight of mixed monomers.

[0072] In a 500mL four-necked flask, add 4 parts by weight of Changchun Chemical Industry Polyvinyl Alcohol BP-1788, 4 parts by weight of BP-0588, 3 parts by weight TR-17 and 165 parts by weight of water, under stirring conditions, heating Dissolve at 90°C for 50 minutes, then lower the temperature to 50°C, add 1.0 parts by weight of disodium alkyl polyoxyethylene ether succinate monoester sulfonate, 0.5 parts by weight of sulfosuccinate derivatives, and 0.3 parts by weight of sodium bicarbonate Par...

Embodiment 2

[0074] 0.5 parts by weight of ammonium persulfate is dissolved in 20 parts by weight of water to obtain an initiator solution; 125 parts by weight of vinyl acetate, 6 parts by weight of tertiary carbonic acid vinyl ester monomer VeoVa-9, 5 parts by weight of VeoVa -10. 3 parts by weight of acetoacetoxy ethyl methacrylate, 7 parts by weight of hydroxyethyl methacrylate, and 2 parts by weight of methacrylic acid were mixed and stirred evenly to prepare a total of 148 parts by weight of the mixed monomer.

[0075] In a 500 mL four-necked flask, add 5 parts by weight Shanghai Petrochemical polyvinyl alcohol PVA1792, 3 parts by weight Nippon Gosei Chemical polyvinyl alcohol WR-14, 4 parts by weight Changchun Chemical Industry polyvinyl alcohol BP-0588 and 173 parts by weight Count the water, under stirring conditions, heat to 93°C to dissolve for 55 minutes, then cool down to 55°C, add 1.2 parts by weight of alkylphenol allyl polyether sulfate, alkyl polyoxyethylene ether succinic a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com