Trimethylolpropane triacrylate and preparation method thereof

A technology of trimethylolpropane triacrylate and trimethylolpropane, which is applied in the field of trimethylolpropane triacrylate and its preparation, can solve the problems of restricting industrial application and development, poor polymerization inhibition effect, and long production cycle and other issues, to achieve the effects of reducing production costs, less human injury, and less by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

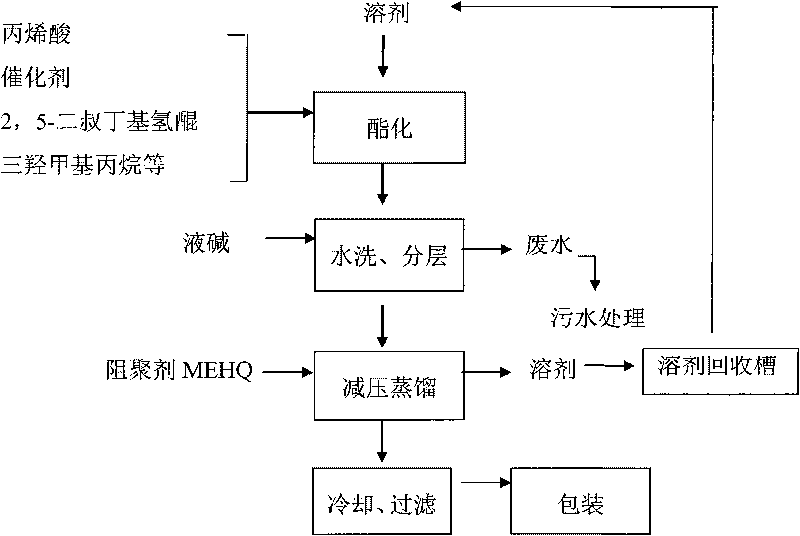

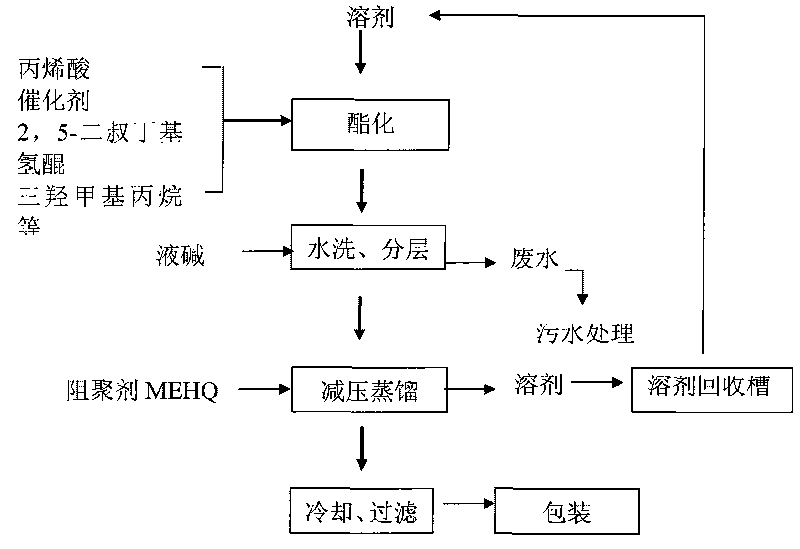

Image

Examples

Embodiment 1

[0031] A method for producing trimethylolpropane triacrylate, the method comprises the following processing steps:

[0032] (1) 30kg of toluene, 20kg of trimethylolpropane, 4kg of p-toluenesulfonic acid, 80g of 2,5-di-tert-butylhydroquinone, and 38kg of acrylic acid are placed in a reaction kettle, stirred and reacted for 2h, and esterified to obtain a reaction solution ;

[0033] (2) Turn on the vacuum pump, control the pressure in the reactor at -0.08MPa, then increase the temperature in the reactor until reflux occurs, keep the reflux for 1h, and stop heating when detecting that the mass fraction of hydroxyl groups in the reaction solution is 2%;

[0034] (3) Add liquid caustic soda in the reaction kettle, control the pH value of solution to be 7, then leave standstill stratification, the waste water of lower layer imports sewage treatment system;

[0035] (4) add p-hydroxyanisole 16g in the solution that removes waste water, remove toluene under reduced pressure distillat...

Embodiment 2

[0037] A method for producing trimethylolpropane triacrylate, the method comprises the following processing steps:

[0038] (1) 120 kg of toluene, 100 kg of trimethylolpropane, 20 kg of p-toluenesulfonic acid, 320 g of 2,5-di-tert-butylhydroquinone, and 160 kg of acrylic acid are placed in a reaction kettle, stirred and reacted for 5 hours, and esterified to obtain a reaction solution ;

[0039] (2) Turn on the vacuum pump, control the pressure in the reaction kettle at -0.09MPa, then increase the temperature in the reaction kettle until reflux occurs, keep the reflux for 1.5h, and stop heating when the mass fraction of hydroxyl groups in the reaction solution is detected to be 3%. ;

[0040] (3) Add liquid caustic soda in the reaction kettle, control the pH value of solution to be 7, then leave standstill stratification, the waste water of lower layer imports sewage treatment system;

[0041] (4) add polymerization inhibitor MEHQ80g in the solution that removes waste water,...

Embodiment 3

[0043] A method for producing trimethylolpropane triacrylate, the method comprises the following processing steps:

[0044] (1) Put 3000kg of toluene, 2500kg of trimethylolpropane, 600kg of p-toluenesulfonic acid, 10kg of 2,5-di-tert-butylhydroquinone, and 450kg of acrylic acid in a reaction kettle, stir and react for 9h, carry out esterification reaction, and obtain a reaction solution ;

[0045] (2) Turn on the vacuum pump, control the pressure in the reactor at -0.1MPa, then increase the temperature in the reactor until reflux occurs, keep the reflux for 9 hours, and stop heating when the mass fraction of hydroxyl groups in the reaction solution is detected to be 3%.

[0046] (3) Add liquid caustic soda in the reaction kettle, control the pH value of solution to be 8, then leave standstill stratification, the waste water of lower layer imports sewage treatment system;

[0047] (4) add p-hydroxyanisole 4kg in the solution that removes waste water, remove toluene under reduc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com