A Identification Method Applied to Petroleum Drill Pipe Operation

A technology of identification and oil drill pipe, which is applied in electromagnetic radiation induction, induction record carrier, instrument, etc., can solve the problems of easy staining and wear of barcodes, achieve automatic machine reading, improve safety, and reduce total cost. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

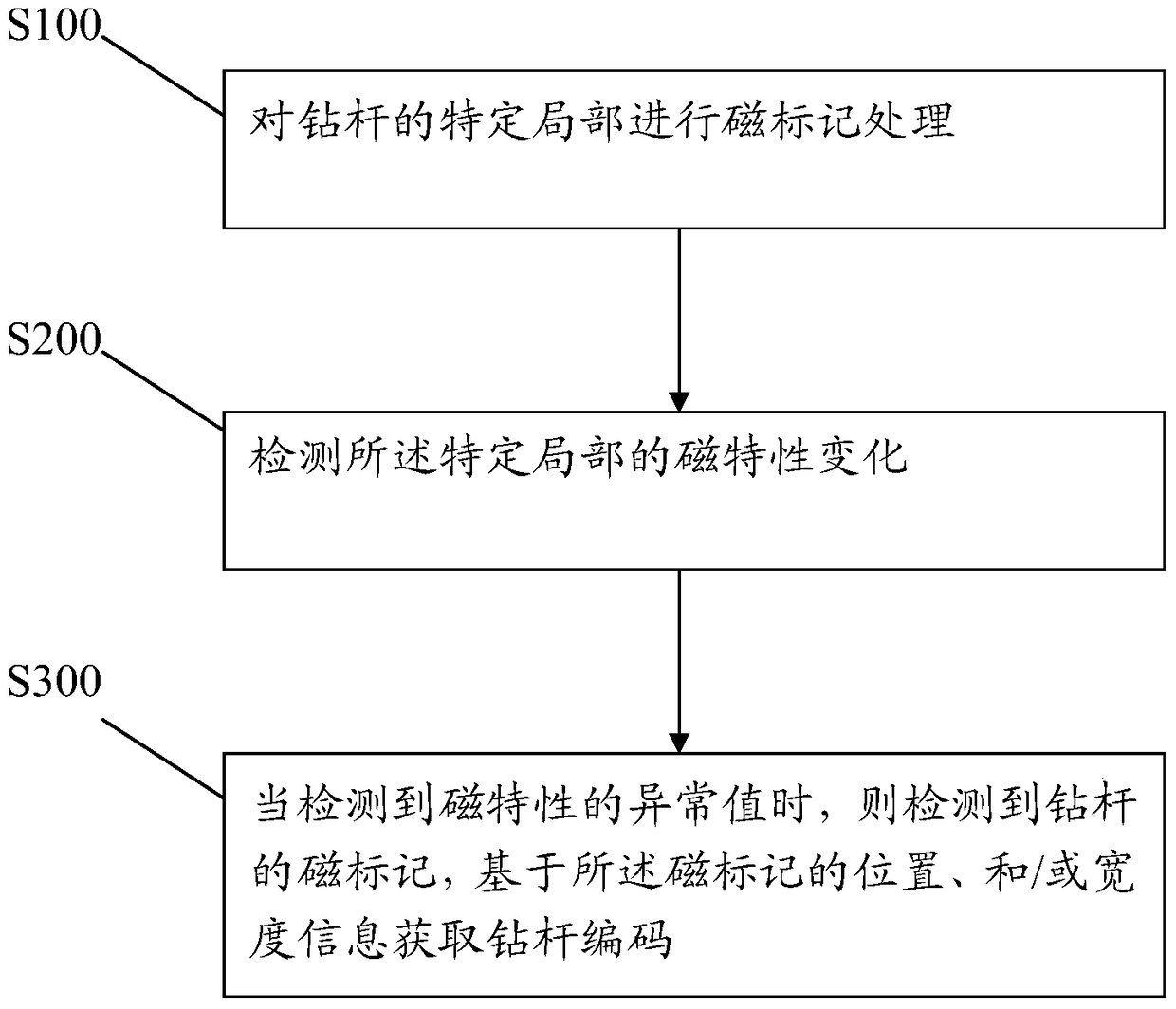

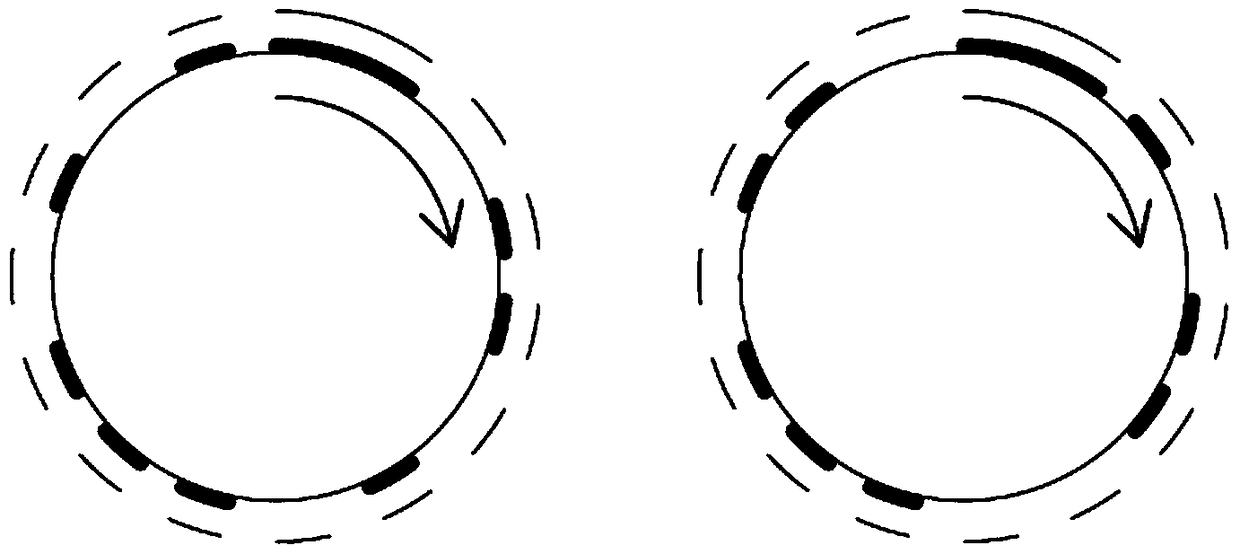

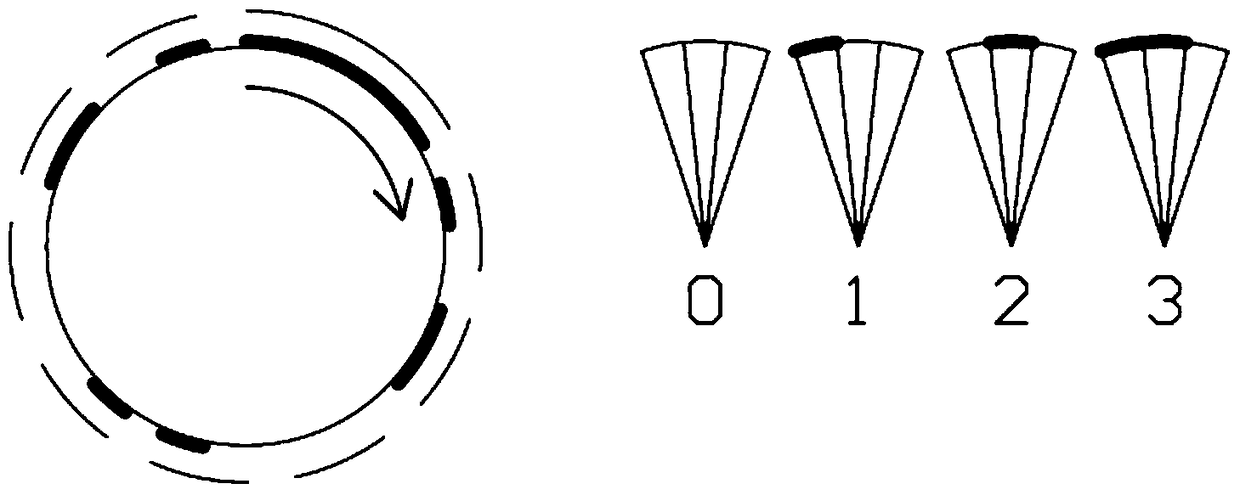

[0026] Please refer to figure 1 , the identification method applied to oil drill pipe operations of the present invention includes: S100, performing magnetic marking processing on a specific part of the drill pipe; S200, detecting the change of the magnetic properties of the specific part; S300, when detecting the abnormality of the magnetic properties value, the magnetic mark of the drill pipe is detected, and the code of the drill pipe is obtained based on the position, width and / or magnetic anomaly amplitude information of the magnetic mark.

[0027] Preferably, the magnetic properties include magnetic permeability, and as a specific embodiment, the magnetic field heat treatment includes increasing magnetic permeability.

[0028] Preferably, the magnetic properties include a squareness ratio of a hysteresis loop. As a specific embodiment, the magnetic field heat treatment includes improving the squareness ratio of the hysteresis loop, or keeping the magnetic permeability c...

example

[0067] Drill pipe code

[0068] The identification method of this embodiment can also be applied to oil pipes and other downhole tools.

Embodiment 2

[0070] The identification method applied to oil drill pipe operations in this embodiment includes: S100, performing magnetic marking processing on a specific part of the drill pipe; S200, detecting changes in the magnetic properties of the specific part; S300, when the magnetic properties are detected When the abnormal value is detected, the magnetic mark of the drill pipe is detected, and the code of the drill pipe is obtained based on the position, width and / or magnetic anomaly amplitude information of the magnetic mark.

[0071] Preferably, the magnetic properties include magnetic permeability, and as a specific embodiment, the magnetic field heat treatment includes increasing magnetic permeability.

[0072] Preferably, the magnetic properties include a squareness ratio of a hysteresis loop. As a specific embodiment, the magnetic field heat treatment includes improving the squareness ratio of the hysteresis loop, or keeping the magnetic permeability constant within a certai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com