Through hole type single-action double-tube drill tool

A single-acting double-tube, through-hole technology, which is applied in the direction of drill bits, drill pipes, drill pipes, etc., can solve the problems of slag dropping, dirty hole bottom, and unsatisfactory punching effect, and achieve improved integrity rate and flow rate. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

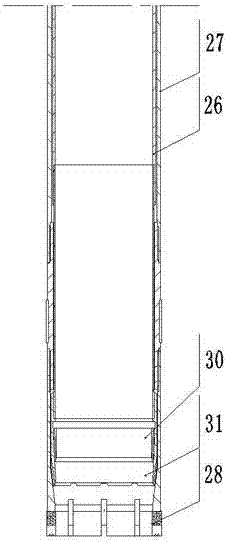

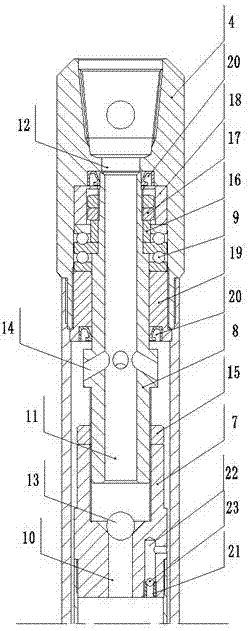

[0036]A through-hole single-action double-tube drilling tool, comprising an inner tube 1 and an outer tube 2 sleeved outside the inner tube 1, the bottom of the outer tube 2 is connected with a diamond drill bit 3, and the upper end of the outer tube 2 is connected to the upper drive The joint 4 is connected; the bottom of the inner tube 1 is provided with a circlip seat 5, and the circlip seat 5 is provided with a circlip 6; the upper end of the inner tube 1 is rotatably connected with the upper drive joint 4 through a connecting part, and the connection A flushing passage communicating with the inner tube 1 is provided on the components and the upper drive joint 4 .

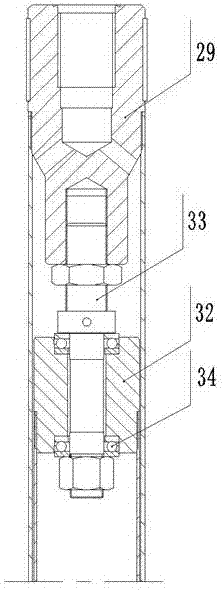

[0037] The connecting parts include an inner pipe joint 7 and a main shaft 8, the upper end of the inner pipe 1 is connected to the inner pipe joint 7, the upper end of the inner pipe joint 7 is connected to the main shaft 8, and the upper end of the main shaft 8 is connected to the upper end through a thrust ba...

Embodiment 2

[0043] As an optimization of Embodiment 1, the upper end of the inner pipe joint 7 is connected to the main shaft 8 through threads, and the main shaft 8 is provided with an inner pipe adjusting nut 15 .

[0044] The upper end of the main shaft 8 is provided with a retaining ring 16 cooperating with the thrust ball bearing 9 and a locking nut 17 locking the retaining ring 16 . The locking nut 17 is covered with a screw cover 18 .

[0045] A seal sleeve 19 is provided on the main shaft 8 between the thrust ball bearing 9 and the flushing side hole 14 .

[0046] An oil seal 20 is arranged on the main shaft 8 at the upper end of the screw cover 18 and the lower end of the sealing sleeve 19 .

[0047] The inner pipe joint 7 is also provided with an overflow hole 21, the inner port of the overflow hole 21 communicates with the inner pipe 1, and the outer port communicates with the gap between the inner pipe 1 and the outer pipe 2; the overflow hole 21 contains There is a vertical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com