Gas Extraction Device

A product and pipeline technology, applied in the field of gas extraction devices, can solve problems such as poor consistency of cells, deviation of analysis results, large number of cells and storage resources, etc., to improve efficiency and accuracy, simplify the process of gas extraction, The effect of ensuring reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The gas production extraction device of the present invention will be described in detail below with reference to the drawings.

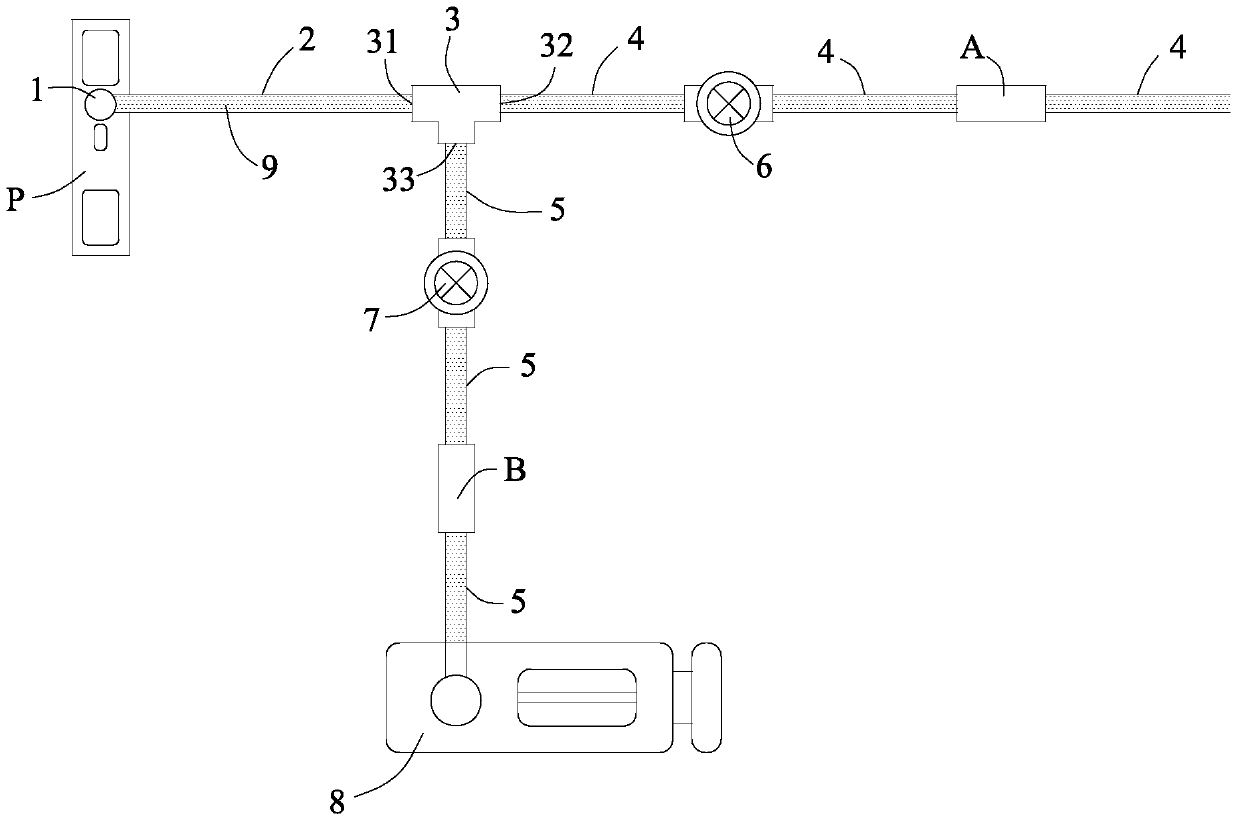

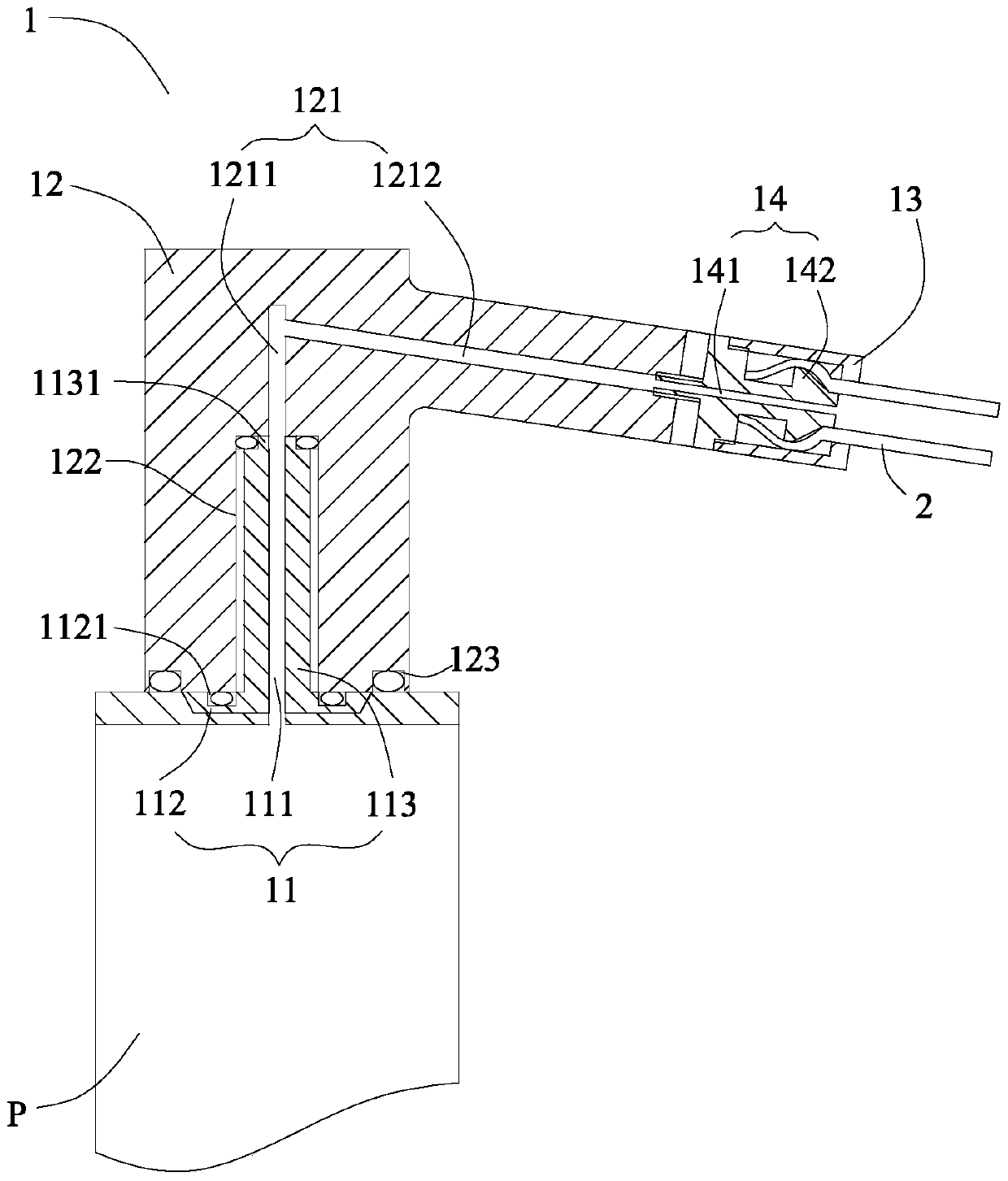

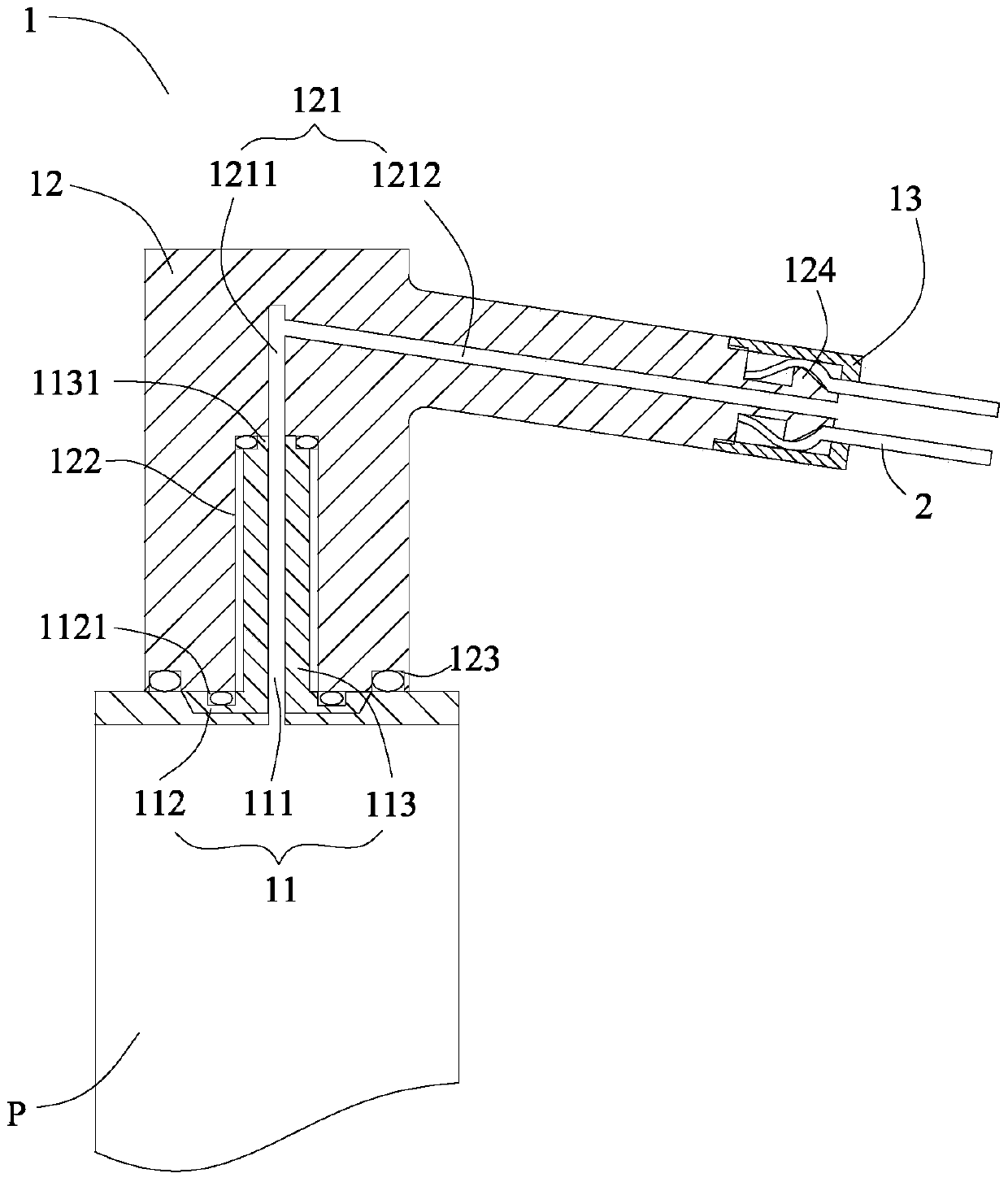

[0031] Reference Figure 1 to Figure 5 , The gas extraction device according to the present invention includes: a first pipe 2, one end of which is connected to the inside of the product P; a joint 3, connected to the other end of the first pipe 2; a second pipe 4, connected to the first pipe 2 via the joint 3 The third pipeline 5 is connected to the first pipeline 2 and the second pipeline 4 via the joint 3; the first valve 6 is arranged on the second pipeline 4; the second valve 7 is arranged on the third pipeline 5; pressure pump 8. Connected to the other end of the third pipe 5; and the sealing liquid 9 is filled in the first pipe 2, the second pipe 4, the third pipe 5 and the joint 3, and does not flow into the product P.

[0032] In the gas extraction device according to the present invention, when the gas produced by the product P needs to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com