Supporting device for coal seam gas extraction drilling and using method thereof

A support device and gas technology, which is applied in the direction of gas discharge, safety devices, mining equipment, etc., can solve problems such as limited support force, influence on gas drainage work, and hole collapse, so as to improve the support effect, prevent hole collapse, The effect of preventing collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1 A support device for coal seam gas drainage drilling

[0027] In this embodiment, by setting the non-return assembly on the leg 2, when the leg 2 pops out of the drill hole for support, it can effectively prevent the leg 2 from shrinking and recovering in the receiving groove 3, and the supporting position of the leg 2 is fixed to play a role in the drilling. Effective support.

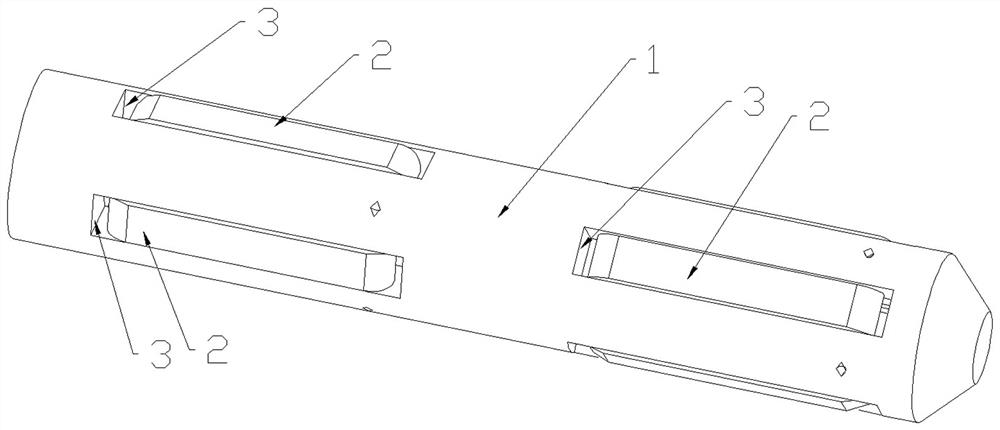

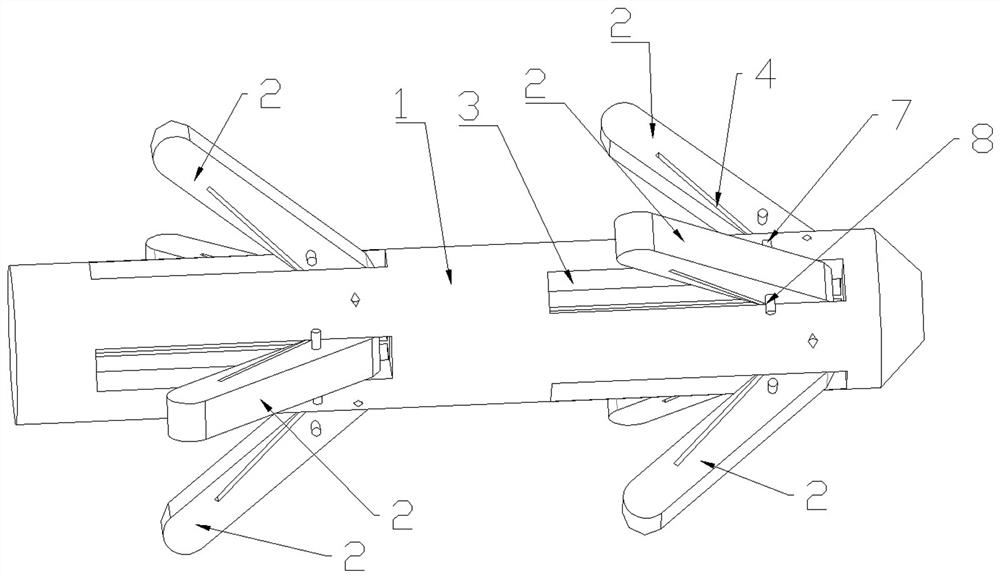

[0028] Such as Figure 1 to Figure 3 As shown, this embodiment includes a bracket main body 1, an elastic foot mechanism and a non-return assembly.

[0029] The bracket main body 1 is a cylinder, the front end of the bracket main body 1 is provided with a conical boss, and the rear end of the bracket main body 1 is provided with a groove, so as to facilitate the transportation and lowering of the bracket main body 1 . The bracket main body 1 is provided with at least one set of elastic leg mechanisms at intervals along the axial direction. In this embodiment, two sets of elastic leg...

Embodiment 2

[0033] Example 2 A method of using a support device for coal seam gas drainage drilling

[0034] This embodiment utilizes the coal seam gas drainage drilling support device in Embodiment 1 to cooperate with the open and close drill bit to realize, including the following steps:

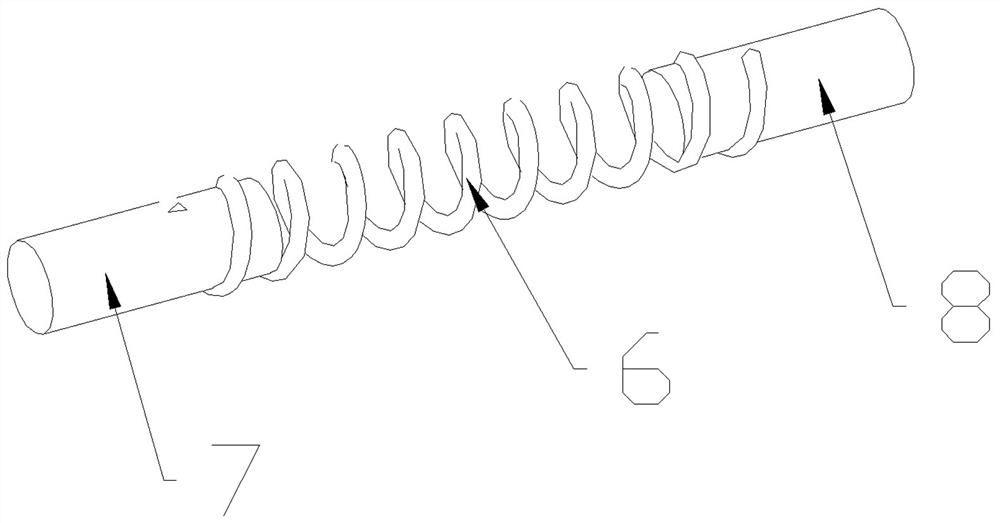

[0035] Such as Figure 4 As shown, the supporting device for coal seam gas drainage drilling is put into the open and close drill bit 9, and under the restriction of the inner wall of the open and close drill bit 9, the support feet 2 are shrunk in the storage groove 3 in the bracket main body 1; Restricted by the groove 3, the spring 6 of the non-return assembly is in a contracted state, so that the first connecting rod 7, the spring 6 and the second connecting rod 8 are limited in the non-return hole 5 of the leg 2, that is, the retracted position of the non-return assembly is in contact with the leg. 2 corresponding to the retracted position.

[0036] Push the bracket main body 1 to advance towar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com