Construction technique for preventing hole collapse of bored cast-in-place pile

A technology of bored piles and construction technology, which is applied in the direction of sheet pile walls, foundation structure engineering, construction, etc., can solve problems such as insufficient lateral support of retaining walls, collapse of hole walls, etc., to overcome insufficient lateral support and improve The effect of drilling success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

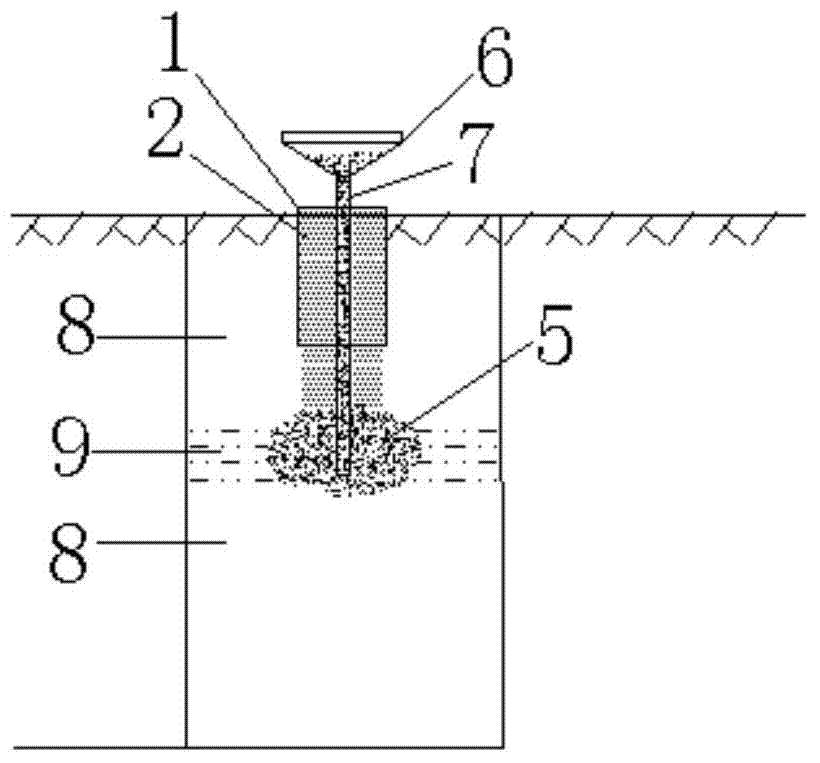

[0025] The present invention adopts following steps:

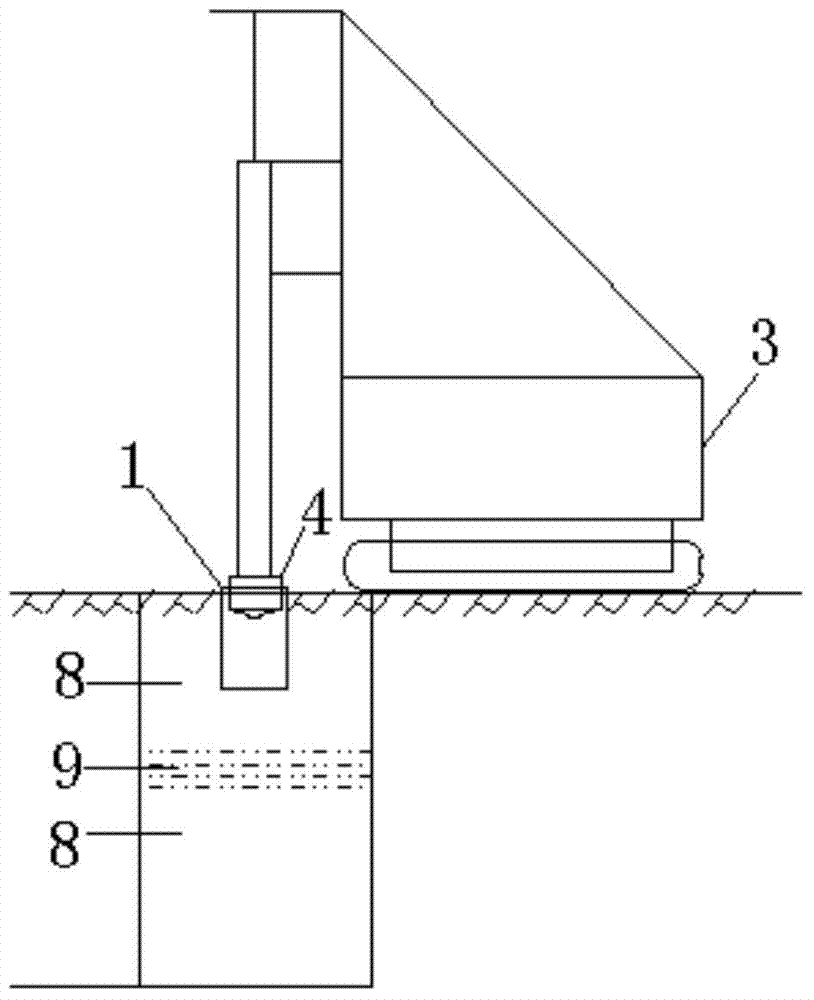

[0026] The first step: if figure 1 As shown, the casing 1 is buried in the soil layer 8 according to the pile position control line, and then the mud circulation system is ready, and the drilling machine 3 is in place. When the set deviation requirements are met, the drilling machine 3 is started, and the drill bit 4 of the drilling machine 3 start drilling;

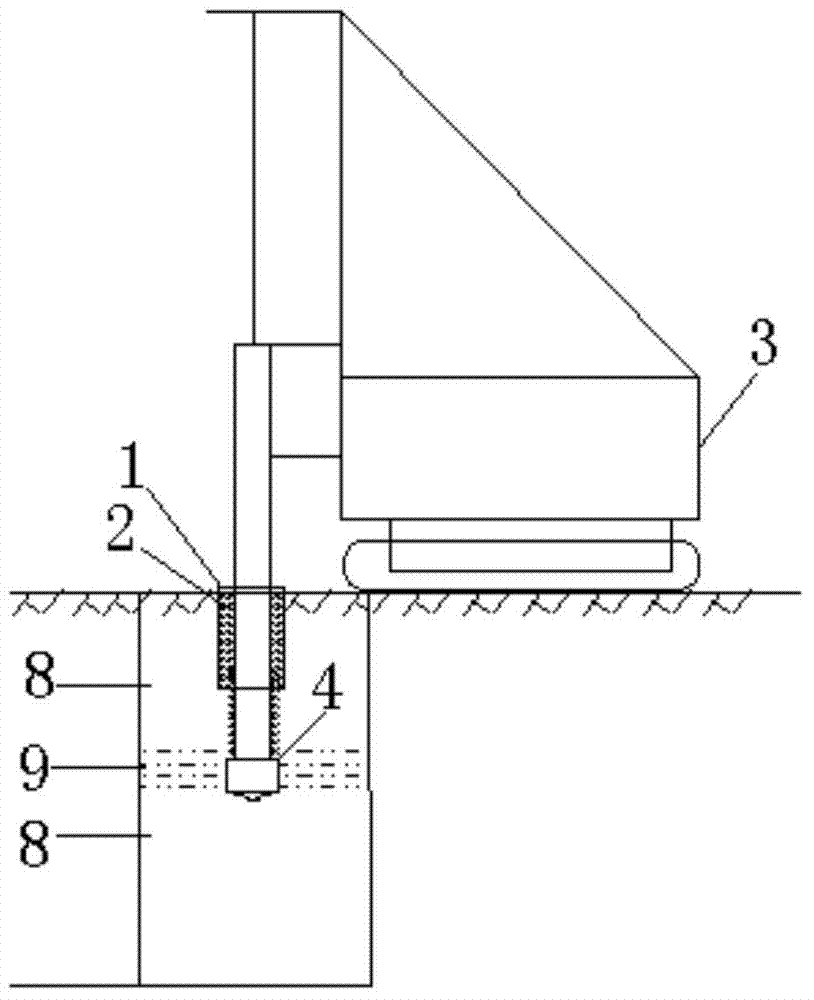

[0027] The second step: if figure 2 As shown, the drill bit 4 of the drilling machine 3 drills normally in the soil layer 8;

[0028] (1) In the process of hole formation, it is necessary to replenish mud 2 in the borehole in time to stabilize the mud in the borehole and maintain the head pressure to play a good role in protecting the wall;

[0029] (2) But when the drill bit 4 penetrates into the soft soil layer 9, because the soft soil layer 9 has strong flow plasticity, the single action of the mud 2 cannot prevent the side wall of the borehole from collapsing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com