Hole collapse prevention construction device and cast-in-place pile construction technology

A construction device and hole collapse technology, which is applied in the direction of drilling with mechanical conveying device, sheet pile wall, foundation structure engineering, etc., can solve the problems affecting the efficiency of pile hole rotary excavation and the construction efficiency of cast-in-situ piles, etc., and achieve improvement Improve construction efficiency, prevent hole collapse, and improve support performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

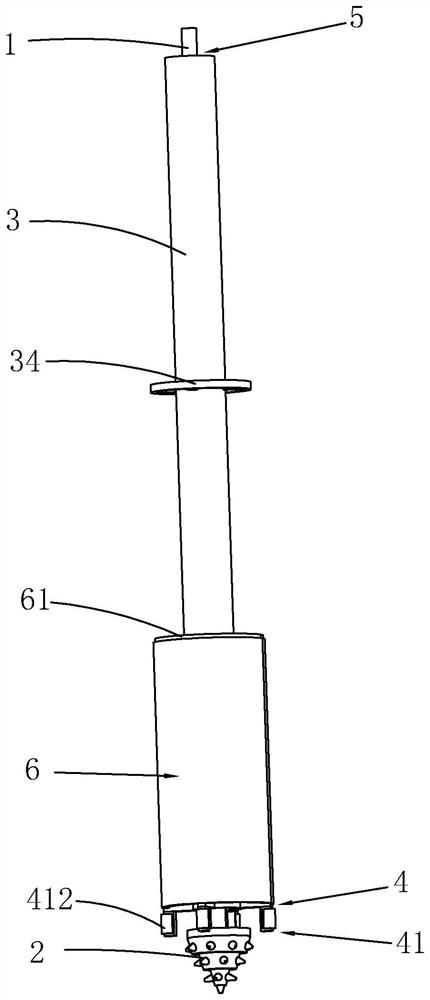

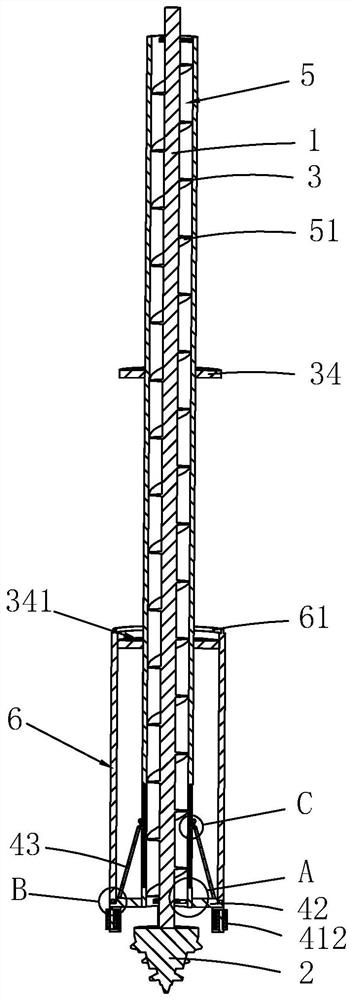

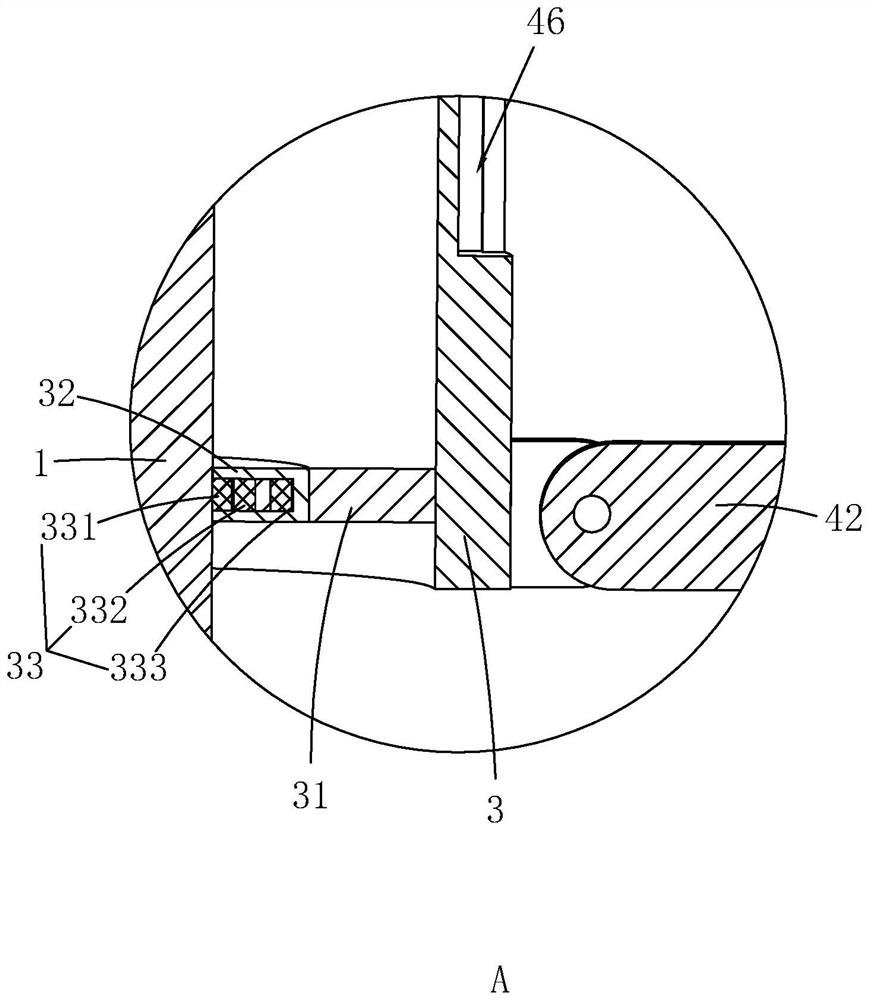

[0049] refer to figure 1 , figure 2 with image 3 , a construction device for preventing collapse includes a drill pipe 1, a rotary drilling bit 2 for rotary digging pile holes, a sleeve 3, at least two sets of connecting rods 31, a lifting assembly 5 for soil extraction, and a casing 6 The supporting assembly 4 that descends synchronously with the rotary drilling bit 2, the rotary drilling bit 2 and the drill pipe 1 are arranged concentrically, the rotary drilling bit 2 is fixedly connected with the suspended end of the drilling pipe 1, and the rotary drilling bit 2 and the drilling pipe 1 are connected by bolts Joint connection; one end of the connecting rod 31 is connected with the inner wall of the sleeve 3, and the other end is rotationally connected with the drill pipe 1. The connecting rod 31 can be set to two groups, three groups, or four groups, and each group The number of connecting rods 31 can be set to three, four, or five, as long as the stable connection betw...

Embodiment 2

[0057] refer to Image 6 with Figure 7 , a construction technique for cast-in-situ piles, comprising the following steps:

[0058] S1. Measure the setting-out positioning pile hole: according to the construction requirements, measure the opening position of the setting-out positioning pile hole and mark it;

[0059] S2. Prefabrication of the casing 6: one end of the casing 6 is integrally connected with the limiting convex rib 61, and the end of the casing 6 away from the limiting convex edge 61 is provided with a limiting groove 62 for inserting the limiting convex rib 61. The casing 6 includes The first arc segment 63 and the second arc segment 64, the first arc segment 63 and the second arc segment 64 are arranged symmetrically about the axis of the casing 6, and the first arc segment 63 is close to the side of the second arc segment 64 At least two positioning rods 65 are provided, and there are two positioning rods 65 in this application, and the positioning rods 65 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com